Yield strength defines the maximum stress a material can withstand without permanent deformation, crucial for structural integrity in engineering applications. Understanding yield strength helps you select materials that ensure safety and performance under load. Explore the full article to learn how yield strength impacts design choices and material selection.

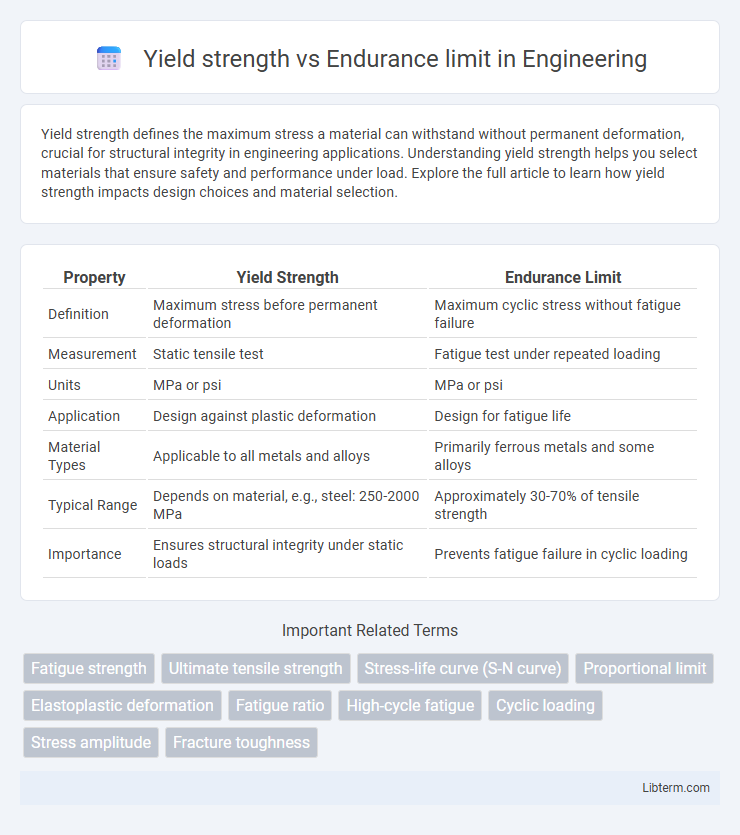

Table of Comparison

| Property | Yield Strength | Endurance Limit |

|---|---|---|

| Definition | Maximum stress before permanent deformation | Maximum cyclic stress without fatigue failure |

| Measurement | Static tensile test | Fatigue test under repeated loading |

| Units | MPa or psi | MPa or psi |

| Application | Design against plastic deformation | Design for fatigue life |

| Material Types | Applicable to all metals and alloys | Primarily ferrous metals and some alloys |

| Typical Range | Depends on material, e.g., steel: 250-2000 MPa | Approximately 30-70% of tensile strength |

| Importance | Ensures structural integrity under static loads | Prevents fatigue failure in cyclic loading |

Introduction to Yield Strength and Endurance Limit

Yield strength defines the maximum stress a material can withstand without permanent deformation, serving as a critical parameter in structural design and safety assessment. The endurance limit represents the stress threshold below which a material can endure an infinite number of load cycles without failure, essential for fatigue analysis in mechanical engineering. Understanding both properties is vital for predicting material behavior under static and cyclic loading conditions.

Definitions: Yield Strength Explained

Yield strength is the stress at which a material begins to deform plastically, marking the transition from elastic to permanent deformation. Endurance limit refers to the maximum stress a material can withstand for an infinite number of load cycles without failure. Understanding yield strength is critical for designing components that must resist permanent distortion under static loads.

Understanding Endurance Limit

The endurance limit is the maximum stress level a material can withstand for an infinite number of load cycles without experiencing fatigue failure, making it critical for designing components subjected to repeated or fluctuating stresses. Yield strength represents the stress at which a material begins to deform plastically, whereas the endurance limit specifically addresses the material's ability to resist crack initiation and propagation under cyclic loading. Understanding the endurance limit allows engineers to predict fatigue life and ensure structural integrity in applications like automotive and aerospace components.

Key Differences Between Yield Strength and Endurance Limit

Yield strength defines the maximum stress a material can withstand without permanent deformation, while endurance limit indicates the maximum stress a material can endure indefinitely under cyclic loading without failure. Yield strength is critical for static applications where permanent deformation must be avoided, whereas endurance limit is essential for components subjected to repeated or fluctuating stresses. Unlike yield strength, which is a single value, the endurance limit often applies only to certain materials like ferrous metals, highlighting their fatigue resistance capabilities.

Importance in Material Selection

Yield strength determines the maximum stress a material can withstand without permanent deformation, crucial for applications requiring structural integrity under static loads. Endurance limit indicates the highest stress a material can endure for an infinite number of cycles without fatigue failure, essential for components subjected to cyclic loading. Selecting materials based on both yield strength and endurance limit ensures durability and safety in engineering designs, balancing immediate load-bearing capacity with long-term fatigue resistance.

Factors Affecting Yield Strength

Yield strength depends on factors such as material composition, grain size, temperature, and work hardening, which influence a material's ability to withstand permanent deformation under stress. Unlike the endurance limit, which specifically concerns cyclic loading and fatigue resistance, yield strength is primarily affected by microstructural features and processing conditions. Alloying elements and heat treatment can significantly enhance yield strength by altering dislocation movement and phase distributions.

Influences on Endurance Limit

Endurance limit is influenced by factors such as surface finish, presence of stress concentrators, and material microstructure, which affect fatigue resistance far more than yield strength does. Yield strength defines the maximum stress a material can withstand without permanent deformation, whereas endurance limit specifically relates to the maximum cyclic stress a material can endure indefinitely without failure. Understanding the influences on endurance limit is critical for designing components subjected to fluctuating stresses to ensure long-term durability.

Applications in Engineering Design

Yield strength defines the maximum stress a material can withstand without permanent deformation, critical for ensuring structural integrity under static loads in engineering design. Endurance limit represents the stress level below which a material can endure infinite cyclic loading without failure, essential for fatigue-sensitive components such as bridges, aircraft, and automotive parts. Selecting materials with appropriate yield strength and endurance limit balances safety and performance, optimizing lifespan and reliability in mechanical and structural applications.

Testing Methods for Yield Strength and Endurance Limit

Yield strength is determined using tensile testing methods, where a specimen is subjected to controlled stress until it deforms plastically, identifying the stress at which permanent deformation begins. Endurance limit testing involves cyclic loading, typically performed through fatigue tests such as rotating bending or axial fatigue tests, to establish the maximum stress a material can withstand for an infinite number of cycles without failure. Both tests require precise instrumentation, with tensile tests focusing on stress-strain curves and fatigue tests analyzing stress-life (S-N) data to assess material performance under static and dynamic loading conditions.

Summary and Practical Considerations

Yield strength defines the maximum stress a material withstands without permanent deformation, while endurance limit represents the maximum stress a material can endure for infinite cycles without fatigue failure. In practical engineering, yield strength ensures structural integrity under static loads, whereas endurance limit is critical for components subjected to repeated or cyclic loading, like springs or rotating shafts. Selecting materials requires balancing these properties to prevent both immediate collapse and long-term fatigue damage.

Yield strength Infographic

libterm.com

libterm.com