Yielding is a critical concept in material science referring to the point at which a material begins to deform plastically under stress, losing its ability to return to its original shape. Understanding yielding helps predict the durability and failure of structures, ensuring safety and performance in engineering applications. Explore the rest of the article to learn how yielding impacts various materials and practical uses in your projects.

Table of Comparison

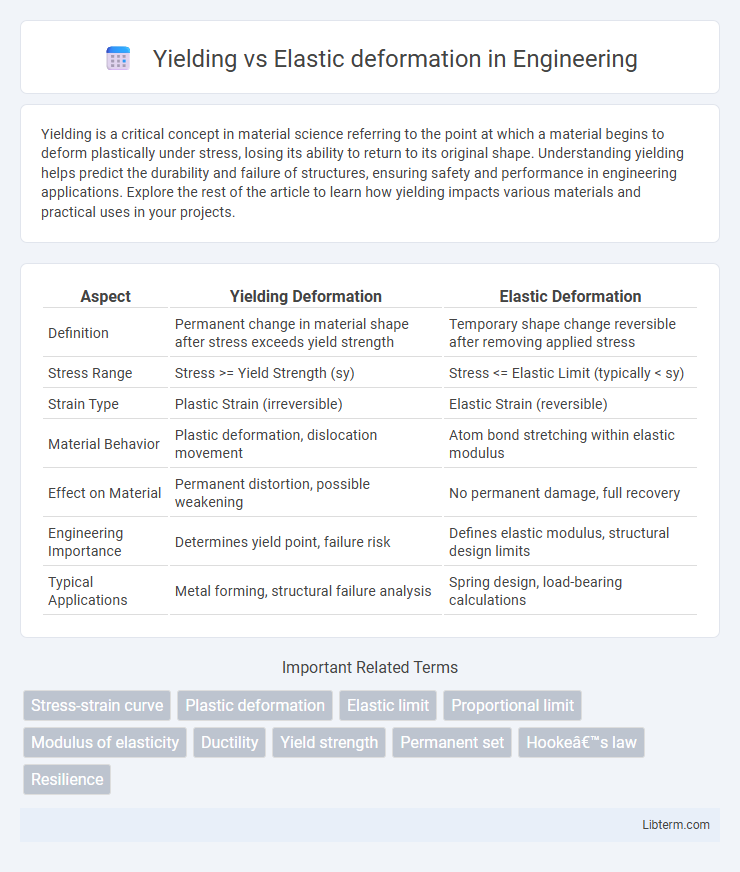

| Aspect | Yielding Deformation | Elastic Deformation |

|---|---|---|

| Definition | Permanent change in material shape after stress exceeds yield strength | Temporary shape change reversible after removing applied stress |

| Stress Range | Stress >= Yield Strength (sy) | Stress <= Elastic Limit (typically < sy) |

| Strain Type | Plastic Strain (irreversible) | Elastic Strain (reversible) |

| Material Behavior | Plastic deformation, dislocation movement | Atom bond stretching within elastic modulus |

| Effect on Material | Permanent distortion, possible weakening | No permanent damage, full recovery |

| Engineering Importance | Determines yield point, failure risk | Defines elastic modulus, structural design limits |

| Typical Applications | Metal forming, structural failure analysis | Spring design, load-bearing calculations |

Introduction to Material Deformation

Material deformation occurs when external forces cause a change in shape or size, classified primarily into yielding and elastic deformation. Elastic deformation is reversible, where the material returns to its original shape after removing the load, governed by the stress-strain relationship within the elastic limit. Yielding marks the onset of permanent deformation, indicating the material has surpassed its yield strength and will not fully recover its initial dimensions.

What is Elastic Deformation?

Elastic deformation refers to the reversible change in shape or size of a material when subjected to stress, where the material returns to its original form once the load is removed. This type of deformation occurs within the material's elastic limit, characterized by a linear relationship between stress and strain as described by Hooke's Law. Unlike yielding, which results in permanent deformation, elastic deformation is temporary and does not cause any lasting structural damage.

What is Yielding in Materials?

Yielding in materials refers to the point at which a material begins to deform plastically and undergoes permanent shape change under applied stress. It marks the transition from elastic deformation, where the material can return to its original shape, to plastic deformation, where the changes are irreversible. Yield strength is a critical property that defines the stress level at which yielding occurs, influencing material selection in engineering and design.

Key Differences: Elastic vs Yield Deformation

Elastic deformation is a reversible change in shape or size when a material is subjected to stress within its elastic limit, meaning it returns to its original form once the stress is removed. Yielding represents the point at which a material undergoes permanent deformation, surpassing the elastic limit and causing irreversible structural changes. The key difference lies in elastic deformation being fully recoverable, while yielding results in permanent alteration of the material's shape.

Stress-Strain Curve Explained

The stress-strain curve illustrates elastic deformation as the initial linear portion where stress and strain are proportional, allowing the material to return to its original shape upon unloading. Yielding marks the transition point on the curve, often identified by the yield strength, where permanent plastic deformation begins, and the material no longer returns to its original shape. Beyond yielding, the curve shows plastic deformation characterized by strain hardening until ultimate tensile strength is reached, followed by necking leading to fracture.

Factors Influencing Elastic and Plastic Behavior

Material composition, temperature, and strain rate significantly influence elastic and plastic deformation behaviors, dictating whether a material yields or remains within its elastic limit. Microstructural features such as grain size, dislocation density, and phase distribution also affect a material's ability to undergo elastic recovery or permanent plastic deformation. Stress state and loading conditions further determine the transition from elastic to plastic behavior, impacting yield strength and ductility.

Significance of Yield Point in Engineering

The yield point marks the transition from elastic to plastic deformation, indicating the maximum stress a material can withstand without permanent shape change. Recognizing the yield point is crucial in engineering design to ensure structures maintain integrity under operational loads without experiencing irreversible damage. Accurate identification of this threshold enables engineers to select appropriate materials and design safety margins, preventing structural failures.

Real-World Examples of Elastic and Yield Deformation

Elastic deformation occurs in everyday items like rubber bands and springs, which return to their original shape after being stretched or compressed. Yielding deformation is seen in materials like metals during metalworking or structural steel under heavy loads, where the material undergoes permanent shape change beyond its elastic limit. Bridge supports and automotive suspension components frequently experience elastic deformation during normal operation but can yield under excessive stress or impact.

Importance in Material Selection and Design

Yielding and elastic deformation are critical factors in material selection and design, as they determine a material's ability to withstand applied stresses without permanent shape changes. Elastic deformation allows structures to absorb and release energy without damage, ensuring durability and service life under normal operational loads. Understanding the yield strength helps engineers select materials that prevent irreversible deformation, thus maintaining structural integrity and safety in applications ranging from aerospace to civil engineering.

Conclusion: Implications for Engineering and Manufacturing

Yielding indicates permanent deformation beyond the elastic limit, critical for defining material failure points in engineering design and manufacturing processes. Elastic deformation allows materials to return to their original shape, essential for applications requiring resilience and repeated stress tolerance. Understanding the balance between yielding and elastic deformation guides the selection of suitable materials to ensure structural integrity and longevity in manufactured products.

Yielding Infographic

libterm.com

libterm.com