Lobe pumps deliver efficient, gentle handling of viscous fluids with minimal pulsation and shear, making them ideal for food processing, pharmaceuticals, and chemical industries. Their robust design enables reliable performance in demanding applications while maintaining product integrity. Discover how your operations can benefit from the versatility and durability of lobe pumps in the rest of this article.

Table of Comparison

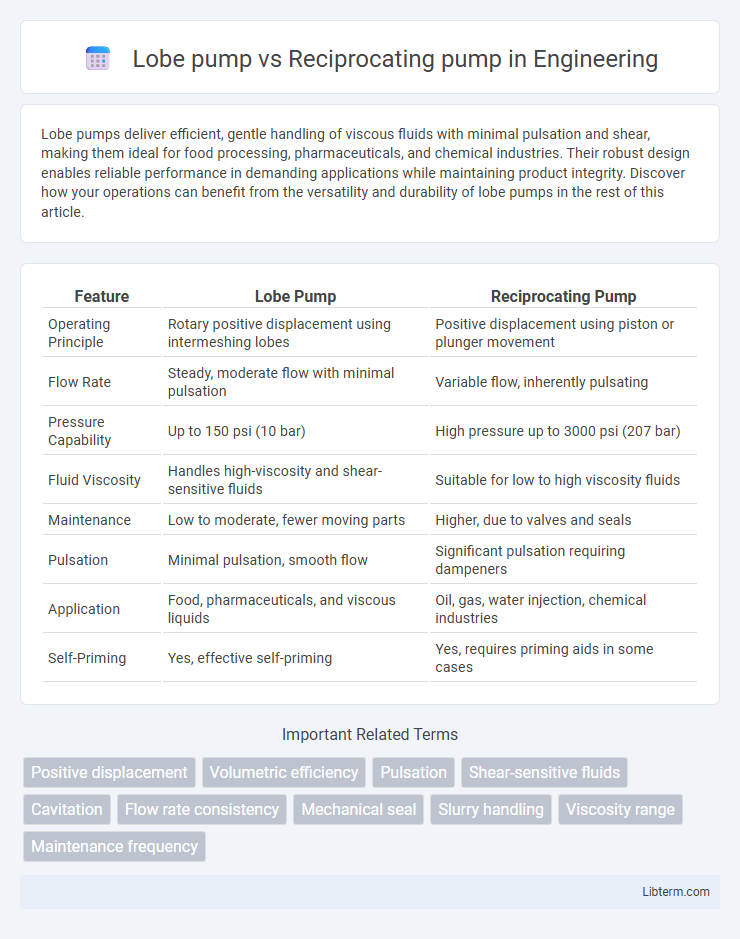

| Feature | Lobe Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Rotary positive displacement using intermeshing lobes | Positive displacement using piston or plunger movement |

| Flow Rate | Steady, moderate flow with minimal pulsation | Variable flow, inherently pulsating |

| Pressure Capability | Up to 150 psi (10 bar) | High pressure up to 3000 psi (207 bar) |

| Fluid Viscosity | Handles high-viscosity and shear-sensitive fluids | Suitable for low to high viscosity fluids |

| Maintenance | Low to moderate, fewer moving parts | Higher, due to valves and seals |

| Pulsation | Minimal pulsation, smooth flow | Significant pulsation requiring dampeners |

| Application | Food, pharmaceuticals, and viscous liquids | Oil, gas, water injection, chemical industries |

| Self-Priming | Yes, effective self-priming | Yes, requires priming aids in some cases |

Introduction to Lobe Pumps and Reciprocating Pumps

Lobe pumps utilize rotating lobes to transfer fluids gently, making them ideal for handling viscous or shear-sensitive materials in industries like food processing and pharmaceuticals. Reciprocating pumps operate by the back-and-forth motion of a piston or diaphragm, providing precise flow control and high-pressure capability suited for chemical dosing and hydraulic systems. Both types offer distinct advantages based on fluid characteristics and application requirements.

Working Principle of Lobe Pumps

Lobe pumps operate by using two or more lobed rotors rotating in opposite directions within a casing, creating cavities that trap and transport fluid from the inlet to the outlet without internal contact, ensuring gentle handling of viscous and shear-sensitive materials. In contrast, reciprocating pumps rely on a piston or plunger moving back and forth to create a pressure differential that draws in and displaces fluid. The lobe pump's positive displacement mechanism provides consistent flow rates and is highly efficient for applications requiring sanitation and minimal pulsation, such as food processing and pharmaceuticals.

Working Principle of Reciprocating Pumps

Reciprocating pumps operate using a piston or plunger that moves back and forth within a cylinder, creating suction and pressure to draw fluid into the chamber and then force it out through a discharge valve. This positive displacement mechanism allows for precise flow control and high pressure output, making reciprocating pumps ideal for applications requiring consistent and accurate fluid delivery. Unlike lobe pumps, which rely on rotating lobes to trap and move fluid, reciprocating pumps convert linear motion into hydraulic energy for efficient fluid transfer.

Key Design Differences

Lobe pumps feature rotating lobes that create smooth, continuous flow ideal for handling viscous fluids without pulsation, while reciprocating pumps utilize pistons or diaphragms to generate a pulsating flow suitable for high-pressure applications. The design of lobe pumps emphasizes gentle handling and minimal shear, making them preferable in food and pharmaceutical industries, whereas reciprocating pumps are favored for precise dose control and high-pressure delivery in oil and chemical processing. Material selection and sealing mechanisms also differ significantly, with lobe pumps requiring precise clearances to prevent product contamination and reciprocating pumps incorporating robust seals to manage high pressure and avoid leakage.

Performance Efficiency Comparison

Lobe pumps deliver consistent flow with low pulsation and high volumetric efficiency, making them ideal for handling viscous fluids with minimal shear. Reciprocating pumps provide high-pressure output and precise flow control, achieving superior efficiency in applications requiring accurate dosing and high pressure. While lobe pumps excel in smooth, gentle pumping suitable for sanitary uses, reciprocating pumps outperform in energy efficiency under high-pressure conditions and intermittent operation.

Applications and Industries

Lobe pumps excel in hygienic applications such as food processing, pharmaceuticals, and cosmetics due to their gentle product handling and easy cleaning features. Reciprocating pumps are preferred in industries requiring high pressure and precise dosing, including oil and gas, chemical processing, and water treatment. Both pump types serve critical roles where reliability and specific flow control are essential across various manufacturing and processing environments.

Maintenance and Durability

Lobe pumps offer easier maintenance due to their simple design with fewer moving parts, allowing quick access for cleaning and repair, which reduces downtime in industrial applications. Their durability is enhanced by robust construction and resistance to wear, making them suitable for handling viscous fluids and solids without damage. Reciprocating pumps, while efficient in high-pressure applications, require more frequent maintenance because of their complex valve and piston systems that are prone to wear and need regular inspection to ensure longevity.

Cost and Operational Considerations

Lobe pumps generally have higher initial costs due to their complex design but offer lower maintenance expenses and longer operational life in handling viscous fluids, making them cost-effective over time. Reciprocating pumps tend to have lower upfront costs but require more frequent maintenance and experience higher wear and tear due to their pulsating flow and moving seals. Operational considerations include lobe pumps providing smooth, non-pulsating flow ideal for sanitary applications, while reciprocating pumps are better suited for high-pressure, precise dosing tasks despite their increased operational complexity.

Advantages and Disadvantages

Lobe pumps provide gentle, non-pulsating flow ideal for handling viscous fluids and solids with minimal shear, offering easy maintenance and sanitary design suited for food and pharmaceutical industries. Reciprocating pumps deliver high pressure and precise flow control, making them suitable for applications requiring accurate dosing and high head, but they generate pulsating flow and require more frequent maintenance due to complex mechanical parts. Lobe pumps generally have lower pressure capabilities and higher initial cost, whereas reciprocating pumps face challenges with noise, vibration, and potential wear from moving seals.

Choosing the Right Pump for Your Needs

Lobe pumps provide gentle, non-pulsating flow ideal for handling viscous fluids and shear-sensitive materials, making them suitable for food processing and pharmaceutical applications. Reciprocating pumps deliver high-pressure, precise volumetric flow, excelling in applications requiring consistent pressure and high accuracy, such as chemical dosing and hydraulic systems. Choosing the right pump depends on factors like fluid viscosity, pressure requirements, and flow consistency to ensure efficient and reliable operation.

Lobe pump Infographic

libterm.com

libterm.com