Coating enhances the durability and appearance of surfaces by providing a protective layer against corrosion, wear, and environmental damage. Different types of coatings, such as epoxy, polyurethane, and powder coatings, offer specialized benefits tailored to various industries and applications. Discover how the right coating can extend the life of your materials and improve performance by reading the rest of this article.

Table of Comparison

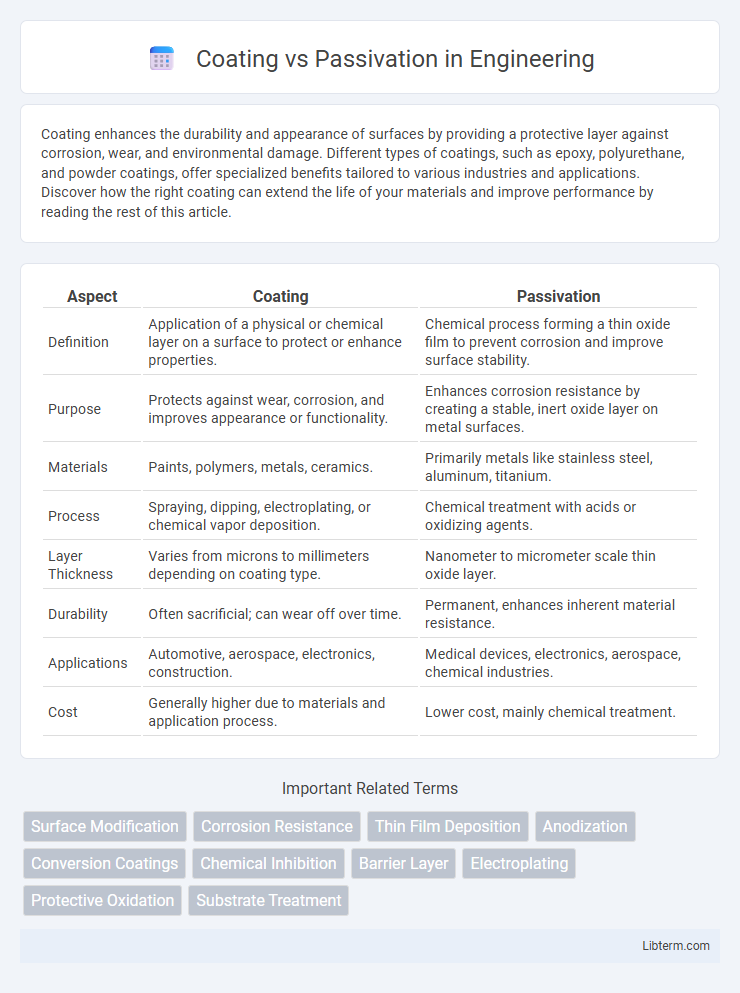

| Aspect | Coating | Passivation |

|---|---|---|

| Definition | Application of a physical or chemical layer on a surface to protect or enhance properties. | Chemical process forming a thin oxide film to prevent corrosion and improve surface stability. |

| Purpose | Protects against wear, corrosion, and improves appearance or functionality. | Enhances corrosion resistance by creating a stable, inert oxide layer on metal surfaces. |

| Materials | Paints, polymers, metals, ceramics. | Primarily metals like stainless steel, aluminum, titanium. |

| Process | Spraying, dipping, electroplating, or chemical vapor deposition. | Chemical treatment with acids or oxidizing agents. |

| Layer Thickness | Varies from microns to millimeters depending on coating type. | Nanometer to micrometer scale thin oxide layer. |

| Durability | Often sacrificial; can wear off over time. | Permanent, enhances inherent material resistance. |

| Applications | Automotive, aerospace, electronics, construction. | Medical devices, electronics, aerospace, chemical industries. |

| Cost | Generally higher due to materials and application process. | Lower cost, mainly chemical treatment. |

Introduction to Surface Protection Methods

Coating and passivation are essential surface protection methods used to enhance material durability and prevent corrosion. Coating involves applying a physical layer such as paint, polymer, or metal plating to create a barrier against environmental factors. Passivation chemically alters the surface, typically through the formation of a thin oxide film, to improve corrosion resistance without adding a separate layer.

What is Coating?

Coating is the application of a protective or decorative layer on a material's surface to enhance durability, corrosion resistance, and aesthetic appeal. Common types include paint, powder coating, and plating, each providing a barrier against environmental factors such as moisture and chemicals. Coatings are essential in industries like automotive, aerospace, and construction for extending the lifespan and performance of metal, plastic, and wooden components.

Understanding Passivation

Passivation is a chemical process that enhances corrosion resistance by creating a thin, inert oxide layer on metal surfaces, commonly applied to stainless steel and aluminum. Unlike coatings, which provide a physical barrier, passivation treats the metal surface at a molecular level to prevent oxidation and improve durability. This process is essential in industries such as aerospace, medical devices, and electronics for maintaining metal integrity and extending component lifespan.

Key Differences Between Coating and Passivation

Coating involves applying a protective layer of material to a surface to shield it from environmental damage, corrosion, or wear, whereas passivation is a chemical process that forms a thin, inert oxide layer on a metal surface to enhance its corrosion resistance. Coatings can be organic or inorganic, such as paint, polymer, or plating, whereas passivation typically involves treatment with acids like nitric or citric acid to remove contaminants and promote oxide film formation. The key difference lies in coatings providing a physical barrier, while passivation improves the metal's inherent corrosion resistance through surface chemistry modification.

Advantages of Coating Techniques

Coating techniques provide enhanced surface protection by forming a physical barrier that resists corrosion, wear, and environmental damage more effectively than passivation. Advanced coatings can be tailored with specific materials like polymers, ceramics, or metals to improve mechanical strength and chemical resistance, extending the lifespan of components. These methods also offer versatile applications across industries such as automotive, aerospace, and electronics, where high durability and aesthetic finishes are crucial.

Benefits of Passivation Processes

Passivation processes enhance the corrosion resistance of metals by forming a thin, protective oxide layer that prevents oxidation and surface degradation. This chemical treatment improves the durability and longevity of stainless steel and other alloys without altering their appearance or dimensional tolerances. Compared to coatings, passivation offers superior adhesion, increased resistance to environmental factors, and reduced maintenance requirements, making it ideal for critical applications in aerospace, medical devices, and food processing industries.

Common Applications for Coating

Coating is widely applied in industries such as automotive, aerospace, and electronics to enhance surface properties like corrosion resistance, wear resistance, and aesthetic appeal. Common coatings include paints, powders, and metallic layers that protect components from environmental damage and extend their service life. Unlike passivation, which chemically stabilizes the surface, coatings create a physical barrier that provides both functional and decorative benefits.

Typical Uses of Passivation

Passivation is typically used to enhance corrosion resistance in stainless steel and other metal surfaces by creating a protective oxide layer that prevents rust and contamination. Common applications include medical instruments, aerospace components, and semiconductor manufacturing, where maintaining surface integrity and cleanliness is critical. This chemical treatment prolongs the lifespan of metals exposed to harsh environmental conditions without altering their dimensions.

How to Choose Between Coating and Passivation

Choosing between coating and passivation depends on the specific application requirements such as corrosion resistance, aesthetics, and environmental conditions. Coating provides a protective layer that can also enhance appearance and offer additional functionalities like UV resistance, while passivation chemically enhances the metal's surface to prevent oxidation without altering its appearance. Evaluate factors like exposure to harsh chemicals, desired durability, maintenance needs, and cost-effectiveness to determine the optimal surface treatment for metals.

Final Thoughts on Surface Protection Solutions

Coating provides a physical barrier that enhances durability and resistance against corrosion, wear, and environmental damage, making it ideal for external surface protection. Passivation chemically improves metal surfaces, particularly stainless steel, by removing free iron and forming a protective oxide layer that prevents rust without altering the metal's appearance. Selecting between coating and passivation depends on application requirements, with coatings suited for aggressive environments and passivation preferred for maintaining metal integrity and corrosion resistance in less exposed conditions.

Coating Infographic

libterm.com

libterm.com