Thrust roller bearings are designed to handle high axial loads while maintaining low friction and efficient operation in machinery. These bearings feature cylindrical rollers arranged to support heavy axial forces, making them ideal for applications like automotive, industrial equipment, and heavy-duty machinery. Explore the rest of the article to understand how thrust roller bearings can enhance your equipment's performance and longevity.

Table of Comparison

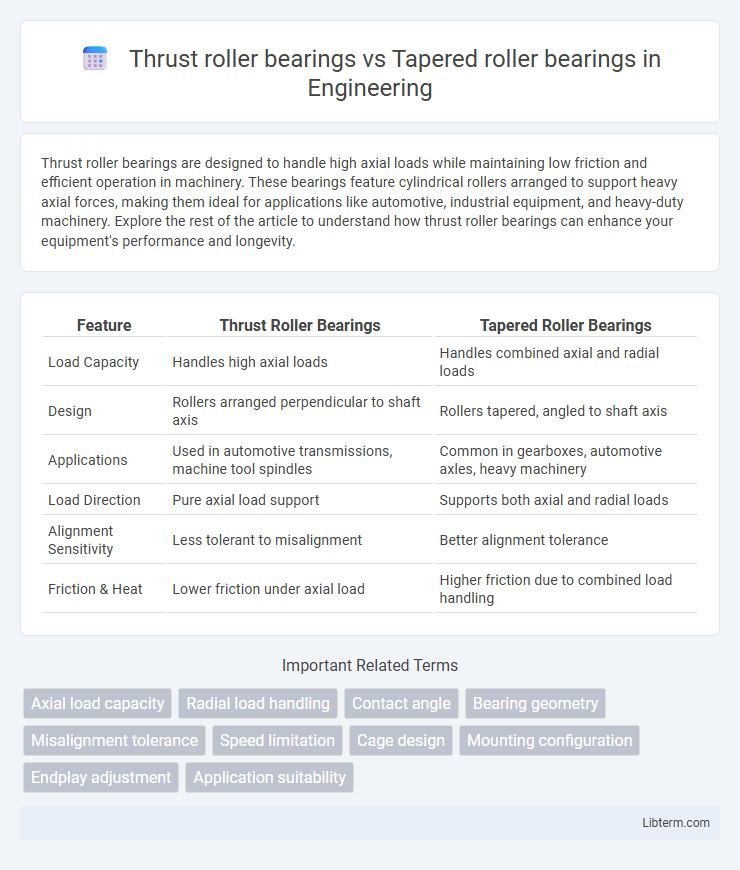

| Feature | Thrust Roller Bearings | Tapered Roller Bearings |

|---|---|---|

| Load Capacity | Handles high axial loads | Handles combined axial and radial loads |

| Design | Rollers arranged perpendicular to shaft axis | Rollers tapered, angled to shaft axis |

| Applications | Used in automotive transmissions, machine tool spindles | Common in gearboxes, automotive axles, heavy machinery |

| Load Direction | Pure axial load support | Supports both axial and radial loads |

| Alignment Sensitivity | Less tolerant to misalignment | Better alignment tolerance |

| Friction & Heat | Lower friction under axial load | Higher friction due to combined load handling |

Introduction to Thrust Roller Bearings and Tapered Roller Bearings

Thrust roller bearings are designed to handle high axial loads in one direction, featuring cylindrical rollers arranged perpendicular to the shaft, enabling efficient support in thrust applications. Tapered roller bearings accommodate both radial and axial loads, with rollers positioned at an angle, allowing them to manage combined loads and reduce friction in rotating machinery. The key distinction lies in their load-handling capabilities and roller orientation, making each suitable for specific mechanical requirements.

Structural Design Differences

Thrust roller bearings feature cylindrical rollers arranged axially to handle high axial loads, with a design that lacks the radial load capacity of tapered roller bearings. Tapered roller bearings incorporate conical rollers set at angles, enabling them to support combined radial and axial loads simultaneously through their cup-and-cone assembly. The key structural difference lies in the roller orientation and raceway geometry, where thrust bearings focus on axial load accommodation, while tapered bearings distribute loads between axial and radial directions.

Load Handling Capabilities

Thrust roller bearings excel at handling high axial loads in one direction, making them ideal for applications with significant thrust forces. Tapered roller bearings manage both radial and axial loads simultaneously due to their angled roller design, offering versatility in load handling. The choice between these bearings depends on the specific load requirements and the directionality of forces in the machinery.

Axial vs. Radial Load Support

Thrust roller bearings excel at handling high axial loads due to their design with rollers oriented parallel to the axis, making them ideal for applications with predominant axial forces. Tapered roller bearings support both radial and axial loads efficiently, thanks to their conical geometry that allows them to accommodate combined load conditions. Selecting between these bearings depends on the specific load requirements: thrust roller bearings for primarily axial load support and tapered roller bearings for balanced radial and axial load management.

Applications in Industry

Thrust roller bearings are primarily used in heavy-duty axial load applications such as gearboxes, machine tool spindles, and marine propulsion systems due to their high axial load capacity and rigidity. Tapered roller bearings handle combined radial and axial loads, making them ideal for automotive wheel hubs, construction machinery, and agricultural equipment where both load types are present. Industrial sectors prioritize thrust roller bearings for vertical shaft support and tapered roller bearings for applications involving complex load directions.

Performance Under High-Speed Operations

Thrust roller bearings exhibit superior axial load capacity and stability in high-speed operations due to their design, which effectively distributes loads along the shaft axis. Tapered roller bearings balance radial and axial loads but tend to generate more heat and experience higher friction at elevated speeds, impacting their performance. Optimizing bearing selection for high-speed machinery involves prioritizing the axial load handling of thrust roller bearings while considering the mixed load capabilities of tapered roller bearings.

Installation and Maintenance Considerations

Thrust roller bearings require precise axial alignment during installation to prevent uneven load distribution and premature wear, while tapered roller bearings demand careful adjustment of both axial and radial clearances to ensure optimal performance. Maintenance for thrust roller bearings involves regular lubrication checks to maintain axial load capacity, whereas tapered roller bearings need frequent inspections for both lubricant condition and bearing preload to avoid misalignment and excess friction. Proper handling and alignment during installation significantly reduce the risk of bearing failure in both types.

Material Selection and Durability

Thrust roller bearings are typically crafted from high-carbon chromium steel to withstand axial loads and resist wear in high-stress environments, while tapered roller bearings utilize heat-treated alloy steel for enhanced durability under combined radial and axial loads. The material selection in both bearing types directly influences their resistance to fatigue, corrosion, and deformation, ensuring operational longevity. Advances in surface coatings and lubrication technologies further improve the durability and performance of these bearings in demanding industrial applications.

Cost Comparison and Economic Factors

Thrust roller bearings generally cost less than tapered roller bearings due to simpler design and lower manufacturing complexity, making them an economical choice for axial load applications. Tapered roller bearings, with higher precision and capability to handle combined radial and axial loads, incur greater material and production expenses, impacting initial investment and maintenance costs. Considering lifespan, load requirements, and application-specific stresses is essential for optimizing cost-effectiveness between these bearing types.

Choosing the Right Bearing for Your Application

Thrust roller bearings excel in handling axial loads and are suitable for applications requiring high axial rigidity, such as machine tool spindles and automotive transmissions, while tapered roller bearings accommodate both radial and axial loads, making them ideal for wheel hubs and gearboxes. Selecting the right bearing depends on load direction, load magnitude, speed, and alignment requirements; thrust roller bearings provide superior axial capacity, whereas tapered roller bearings offer versatility under combined loads. Understanding the operational environment and load characteristics ensures optimal bearing performance, extended service life, and reduced maintenance costs.

Thrust roller bearings Infographic

libterm.com

libterm.com