Reinforcement strengthens behavioral responses by providing positive or negative feedback, enhancing learning and adaptation. It plays a crucial role in shaping habits and decision-making processes, influencing how behaviors are repeated or modified over time. Discover how reinforcement can transform your approach to personal growth and motivation in the rest of this article.

Table of Comparison

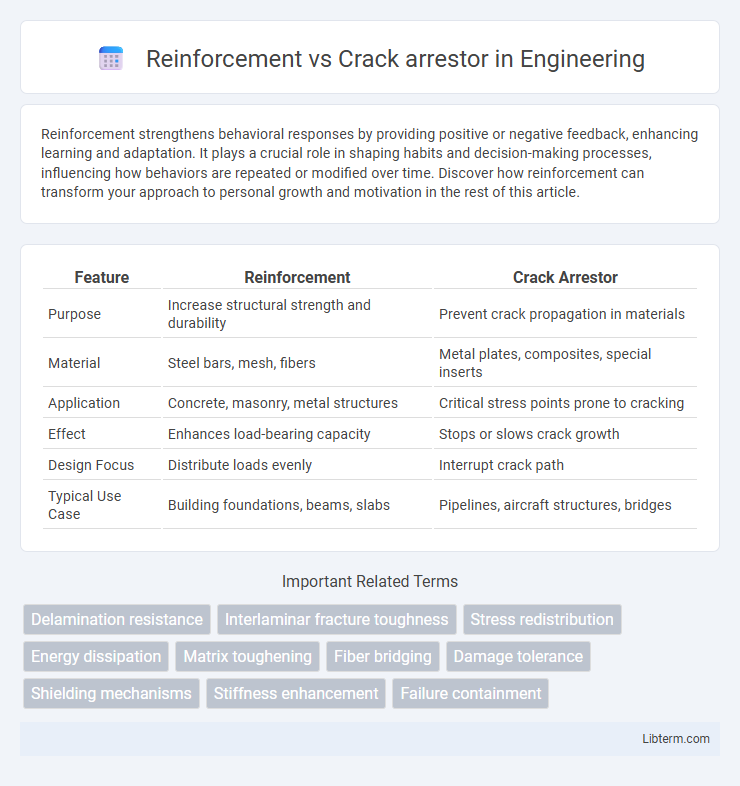

| Feature | Reinforcement | Crack Arrestor |

|---|---|---|

| Purpose | Increase structural strength and durability | Prevent crack propagation in materials |

| Material | Steel bars, mesh, fibers | Metal plates, composites, special inserts |

| Application | Concrete, masonry, metal structures | Critical stress points prone to cracking |

| Effect | Enhances load-bearing capacity | Stops or slows crack growth |

| Design Focus | Distribute loads evenly | Interrupt crack path |

| Typical Use Case | Building foundations, beams, slabs | Pipelines, aircraft structures, bridges |

Introduction to Reinforcement and Crack Arrestors

Reinforcement in construction typically involves embedding steel bars or mesh within concrete to enhance its tensile strength and durability, preventing structural failure. Crack arrestors are specialized devices or design features intended to halt the propagation of cracks within materials, thereby extending the service life of the structure. While reinforcement strengthens the material to resist stress, crack arrestors function as barriers that control crack growth and prevent catastrophic damage.

Core Differences: Reinforcement vs Crack Arrestor

Reinforcement primarily enhances the structural capacity and load-bearing ability of materials by distributing stresses and preventing deformation, while crack arrestors are specifically designed to halt or slow the propagation of cracks within a structure. Reinforcement typically involves continuous elements such as steel bars or fibers integrated into concrete or composites, whereas crack arrestors are often discrete devices or features that localize stress to stop crack growth. Understanding these core differences is critical for optimizing structural integrity, where reinforcement improves overall strength and crack arrestors focus on damage containment.

Material Types Used in Reinforcements and Crack Arrestors

Reinforcements commonly use materials such as carbon fiber, fiberglass, and aramid fibers, chosen for their high tensile strength and lightweight properties that enhance structural durability. Crack arrestors often incorporate metallic alloys like stainless steel or titanium alongside composite materials, designed to dissipate stress and prevent crack propagation effectively. The selection of materials in both reinforcements and crack arrestors critically influences their performance in applications requiring resistance to mechanical fatigue and structural integrity.

Mechanisms of Crack Prevention and Arrest

Reinforcement prevents crack initiation by distributing stresses evenly across a concrete matrix, enhancing tensile strength and reducing localized stress concentrations that cause cracks. Crack arrestors function by interrupting crack propagation paths through embedded barriers, absorbing energy and preventing crack extension. Both mechanisms rely on modifying stress fields and crack tip energy release rates to maintain structural integrity.

Structural Applications and Use Cases

Reinforcements in structural applications enhance load-bearing capacity and distribute stresses across concrete, steel, or composite materials to prevent failure under heavy loads and dynamic forces. Crack arrestors, integrated within structures, localize and halt crack propagation to preserve integrity and extend service life, especially in high-stress zones such as joints, welds, or areas prone to fatigue. Use cases for reinforcements include beams, columns, and slabs in buildings and bridges, while crack arrestors are critical in aerospace, pipelines, and pressure vessels where preventing crack growth is essential for safety and durability.

Performance Comparison: Strength, Durability, and Cost

Reinforcement materials typically offer higher tensile strength and improved load-bearing capacity compared to crack arrestors, making them ideal for structural applications requiring enhanced durability. Crack arrestors excel in preventing crack propagation and extending service life by localizing damage, often resulting in lower long-term maintenance costs but potentially higher initial investment. Cost effectiveness depends on project scale and application, with reinforcement favored for overall strength enhancement, while crack arrestors provide targeted durability benefits in critical stress areas.

Installation Methods and Best Practices

Reinforcement installation typically involves welding or bolting steel plates or bars directly onto concrete or structural surfaces to enhance load-bearing capacity and prevent cracking. Crack arrestors are often embedded into joints or existing cracks using epoxy injection or mechanical anchoring to halt crack propagation effectively. Best practices include ensuring surface preparation for optimal adhesion, using corrosion-resistant materials, and following manufacturer guidelines to maintain structural integrity and prolong service life.

Pros and Cons: Reinforcements vs Crack Arrestors

Reinforcements enhance structural strength by distributing loads and preventing deformation, but may increase weight and material costs. Crack arrestors effectively halt crack propagation, improving durability and safety, although they can complicate design and require precise placement. Balancing the use of reinforcements and crack arrestors depends on the specific engineering requirements, material properties, and long-term performance goals.

Industry Standards and Guidelines

Reinforcement and crack arrestors are critical components in structural engineering, governed by industry standards such as ASTM E647 for fatigue crack growth and ACI 318 for concrete reinforcement requirements. Reinforcement primarily enhances load-bearing capacity and ductility, while crack arrestors are designed to halt crack propagation, ensuring structural integrity under cyclic stresses. Compliance with guidelines from organizations like ISO and ASME ensures proper material selection, placement, and performance verification to meet safety and durability criteria.

Selecting the Right Solution for Your Project

Selecting the right solution between reinforcement and crack arrestors depends on the project's structural requirements and crack management goals. Reinforcement enhances overall load-bearing capacity and durability in concrete or metal structures, while crack arrestors are specialized devices designed to halt the propagation of existing cracks. Evaluating factors such as crack size, location, material type, and environmental exposure ensures optimal performance and longevity in the chosen approach.

Reinforcement Infographic

libterm.com

libterm.com