Extrusion is a manufacturing process that shapes material by forcing it through a die, creating long objects with a fixed cross-sectional profile. This technique is widely used with metals, plastics, and ceramics to produce pipes, rods, and sheets with precise dimensions and smooth surfaces. Discover how extrusion can enhance Your production efficiency and quality by reading the full article.

Table of Comparison

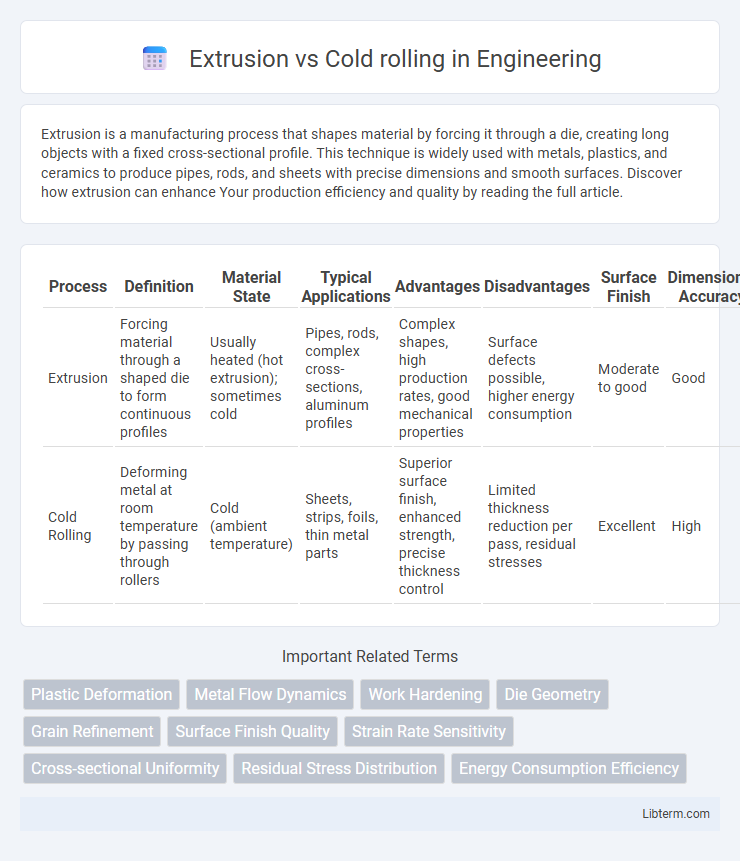

| Process | Definition | Material State | Typical Applications | Advantages | Disadvantages | Surface Finish | Dimensional Accuracy |

|---|---|---|---|---|---|---|---|

| Extrusion | Forcing material through a shaped die to form continuous profiles | Usually heated (hot extrusion); sometimes cold | Pipes, rods, complex cross-sections, aluminum profiles | Complex shapes, high production rates, good mechanical properties | Surface defects possible, higher energy consumption | Moderate to good | Good |

| Cold Rolling | Deforming metal at room temperature by passing through rollers | Cold (ambient temperature) | Sheets, strips, foils, thin metal parts | Superior surface finish, enhanced strength, precise thickness control | Limited thickness reduction per pass, residual stresses | Excellent | High |

Introduction to Extrusion and Cold Rolling

Extrusion is a metal forming process where material is forced through a die to create objects with a fixed cross-sectional profile, commonly used for manufacturing complex shapes with high dimensional accuracy. Cold rolling involves passing metal sheets or strips through rollers at room temperature to reduce thickness, improve surface finish, and enhance mechanical properties through strain hardening. Both processes are essential in metal fabrication, with extrusion excelling in producing intricate profiles and cold rolling optimizing flat products for strength and surface quality.

Process Overview: Extrusion Explained

Extrusion is a manufacturing process that involves forcing heated metal through a die to create objects of a fixed cross-sectional profile. This method allows for complex shapes and tight tolerances, making it ideal for producing components such as pipes, rods, and structural parts. Unlike cold rolling, extrusion shapes materials by deformation at elevated temperatures, improving ductility and reducing internal stresses.

Process Overview: Cold Rolling Unveiled

Cold rolling involves passing metal sheets between rollers at temperatures below the metal's recrystallization point, enhancing surface finish and dimensional accuracy. The process increases material strength through strain hardening while producing uniform thickness, making it ideal for applications requiring precise tolerances. Compared to extrusion, cold rolling delivers superior mechanical properties and improved surface quality without the extensive deformation and heating characteristic of extrusion.

Material Suitability for Each Method

Extrusion is ideal for materials with good plasticity, such as aluminum, copper, and certain plastics, allowing them to be formed into complex cross-sectional shapes. Cold rolling suits metals with excellent ductility, like steel and aluminum alloys, enhancing surface finish and mechanical properties without altering the material's chemical composition. Materials with low ductility or that are brittle generally perform poorly in cold rolling but may be extruded if their temperature and deformation conditions are carefully controlled.

Comparative Analysis of Mechanical Properties

Extrusion produces materials with enhanced tensile strength and uniform grain structure due to the directional flow of metal, resulting in superior ductility compared to cold rolling, which often increases hardness and strength but reduces ductility through strain hardening. Cold rolling improves surface finish and dimensional accuracy, yet may introduce residual stresses that affect fatigue resistance, while extrusion typically yields better impact toughness and isotropic mechanical properties. The choice between extrusion and cold rolling depends on the required balance of mechanical characteristics such as yield strength, elongation, and toughness for specific industrial applications.

Surface Finish and Dimensional Accuracy

Extrusion typically produces a rougher surface finish compared to cold rolling, which delivers smoother and more polished surfaces ideal for aesthetics and further processing. Cold rolling offers superior dimensional accuracy due to precise control over thickness and tighter tolerances, making it suitable for applications requiring exact specifications. Extrusion is more versatile for complex cross-sectional shapes but lacks the fine surface details and consistent dimensional control characteristic of cold-rolled products.

Energy Consumption and Efficiency

Extrusion typically requires higher energy consumption compared to cold rolling due to the intense heat and force needed to shape metals through a die, while cold rolling operates at room temperature, reducing thermal energy use. Cold rolling offers greater energy efficiency by minimizing heating requirements and enabling faster processing speeds, making it more suitable for large-scale production with lower operational costs. Energy consumption in extrusion varies significantly with material properties and die complexity, whereas cold rolling maintains consistent efficiency largely dependent on thickness reduction and rolling mill design.

Application Areas: Industry Use Cases

Extrusion is widely used in industries such as automotive, aerospace, and construction for producing complex cross-sectional profiles like window frames, pipes, and heat sinks. Cold rolling finds extensive application in manufacturing sheets, strips, and foils for packaging, electrical appliances, and automotive body panels due to its ability to enhance surface finish and mechanical properties. Both processes optimize material performance tailored to specific industrial requirements, balancing form complexity and mechanical strength.

Cost Implications and Economic Considerations

Extrusion generally involves higher initial tooling and energy costs compared to cold rolling, but it offers better material utilization and complex cross-sectional shapes, which can reduce waste and secondary processing costs. Cold rolling typically provides lower per-unit costs for high-volume production due to faster processing speeds and less energy consumption, making it more economical for producing thin sheets and strips. Evaluating project scale, material type, and desired product geometry is essential for determining the most cost-effective manufacturing method in extrusion versus cold rolling.

Choosing the Right Process: Key Decision Factors

Choosing between extrusion and cold rolling depends on factors like desired material properties, surface finish, and dimensional precision. Extrusion is ideal for complex cross-sectional profiles and enhanced mechanical strength through hot working, whereas cold rolling provides superior surface finish and tight tolerances ideal for sheet and strip products. Material type, production volume, and cost constraints also significantly influence the optimal process selection.

Extrusion Infographic

libterm.com

libterm.com