Grain boundary strengthening enhances the mechanical properties of metals by impeding dislocation movement, which increases material hardness and strength. Smaller grain sizes create more boundaries, providing greater resistance to deformation and improving overall durability. Explore the rest of the article to understand how grain boundary strengthening can optimize your material performance.

Table of Comparison

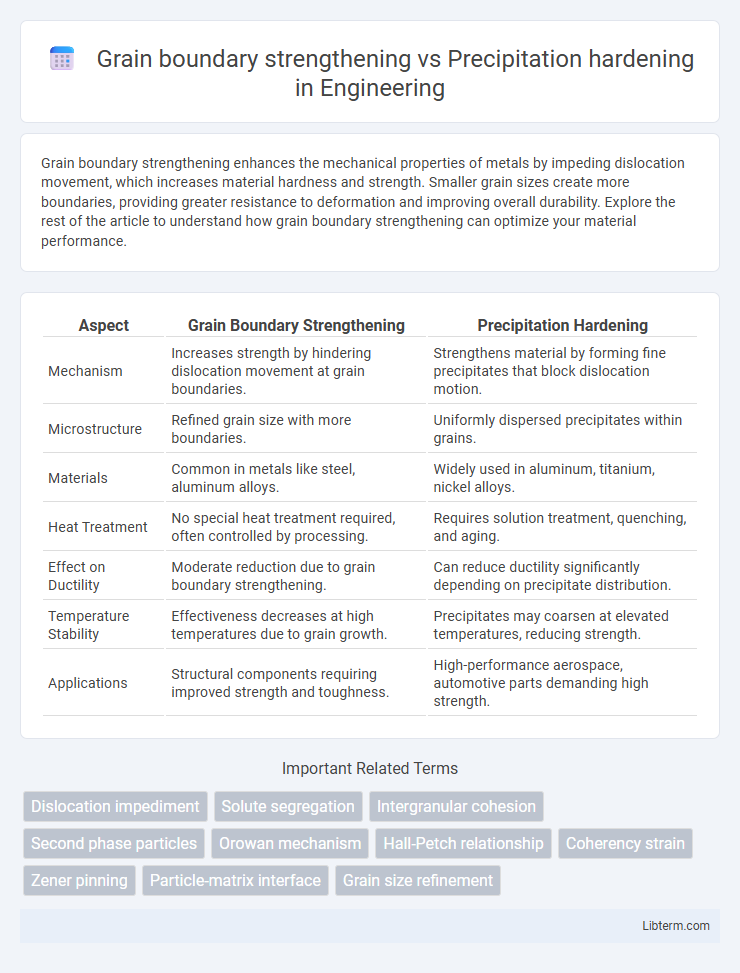

| Aspect | Grain Boundary Strengthening | Precipitation Hardening |

|---|---|---|

| Mechanism | Increases strength by hindering dislocation movement at grain boundaries. | Strengthens material by forming fine precipitates that block dislocation motion. |

| Microstructure | Refined grain size with more boundaries. | Uniformly dispersed precipitates within grains. |

| Materials | Common in metals like steel, aluminum alloys. | Widely used in aluminum, titanium, nickel alloys. |

| Heat Treatment | No special heat treatment required, often controlled by processing. | Requires solution treatment, quenching, and aging. |

| Effect on Ductility | Moderate reduction due to grain boundary strengthening. | Can reduce ductility significantly depending on precipitate distribution. |

| Temperature Stability | Effectiveness decreases at high temperatures due to grain growth. | Precipitates may coarsen at elevated temperatures, reducing strength. |

| Applications | Structural components requiring improved strength and toughness. | High-performance aerospace, automotive parts demanding high strength. |

Introduction to Strengthening Mechanisms

Grain boundary strengthening improves material strength by increasing the number of grain boundaries, which impede dislocation motion and enhance resistance to deformation. Precipitation hardening involves the formation of fine particles within the metal matrix that act as obstacles to dislocation movement, significantly raising yield strength and hardness. Both mechanisms optimize mechanical properties by restricting dislocation mobility but operate through distinct microstructural modifications in metals and alloys.

Overview of Grain Boundary Strengthening

Grain boundary strengthening enhances material strength by increasing the number of grain boundaries, which act as barriers to dislocation movement and impede plastic deformation. Smaller grain sizes result in a higher density of grain boundaries, effectively blocking dislocation slip and enhancing yield strength according to the Hall-Petch relationship. This mechanism is widely used in metals and alloys to improve mechanical properties without altering chemical composition.

Fundamentals of Precipitation Hardening

Precipitation hardening enhances material strength by forming fine, dispersed particles within the metal matrix that impede dislocation motion, significantly improving yield strength and hardness. This process involves solution treating, quenching, and aging, which promotes nucleation and growth of precipitates, optimizing their size and distribution for maximum strengthening effects. Grain boundary strengthening primarily relies on refining grain size to obstruct dislocation movement at grain interfaces, but precipitation hardening provides superior control over strengthening through tailored precipitate phases and morphologies.

Microstructural Changes in Each Mechanism

Grain boundary strengthening involves refining the grain size, creating more grain boundaries that impede dislocation motion and enhance material strength. Precipitation hardening introduces finely dispersed second-phase particles within the matrix, which obstruct dislocation movement through particle shearing or bypass mechanisms. The microstructural change in grain boundary strengthening is characterized by increased grain boundary area, while precipitation hardening results in a uniform distribution of nanoscale precipitates that act as pinning points.

Influences on Yield Strength

Grain boundary strengthening increases yield strength by obstructing dislocation movement at grain interfaces, with smaller grain sizes producing higher strength according to the Hall-Petch relationship. Precipitation hardening enhances yield strength through the formation of finely dispersed particles that impede dislocation glide, with the size, distribution, and coherency of precipitates critically determining the magnitude of strengthening. Both mechanisms contribute significantly to yield strength improvement, but grain boundary strengthening is more effective in fine-grained materials, whereas precipitation hardening is dominant in alloys with tailored precipitate structures.

Grain Size Effect vs Precipitate Distribution

Grain boundary strengthening relies on reducing grain size to increase the total grain boundary area, which impedes dislocation motion and enhances material strength according to the Hall-Petch relationship. Precipitation hardening depends on the size, distribution, and coherency of precipitates within the metal matrix to block dislocations and cause strengthening by obstructing their movement. While grain size directly controls the density of grain boundaries acting as barriers, precipitate distribution governs particle spacing and strength through mechanisms like Orowan looping or shearable precipitates.

Temperature Dependence in Both Mechanisms

Grain boundary strengthening effectiveness decreases at elevated temperatures due to grain boundary sliding and diffusion processes, leading to reduced resistance to deformation. Precipitation hardening maintains higher strength at elevated temperatures as stable precipitates hinder dislocation motion, but coarsening of precipitates can diminish this effect over prolonged exposure. Temperature critically influences the microstructural stability and mechanical performance of both mechanisms, with grain boundaries becoming less effective and precipitates potentially losing strength through morphological changes.

Advantages and Limitations of Grain Boundary Strengthening

Grain boundary strengthening enhances material strength by increasing the number of grain boundaries, which act as barriers to dislocation movement, thereby improving yield strength and hardness. Advantages include improved mechanical properties at elevated temperatures and enhanced resistance to creep and fatigue. Limitations involve potential brittleness due to excessive grain refinement and reduced ductility, as well as challenges in controlling grain size uniformly during processing.

Benefits and Drawbacks of Precipitation Hardening

Precipitation hardening significantly improves material strength and hardness by creating finely dispersed particles that impede dislocation motion, offering superior mechanical properties compared to grain boundary strengthening. This method enhances yield strength and fatigue resistance but can lead to reduced ductility and increased brittleness due to the formation of coarse precipitates if aging is not carefully controlled. Precise heat treatment is required to optimize the size and distribution of precipitates, making the process more complex and sensitive than grain boundary strengthening.

Applications and Industrial Relevance

Grain boundary strengthening is widely utilized in structural steels and aerospace alloys to enhance mechanical properties such as toughness and fatigue resistance by refining grain size, which impedes dislocation movement. Precipitation hardening finds critical applications in aluminum alloys, titanium alloys, and superalloys, significantly improving strength and corrosion resistance through nanoscale precipitate formation that obstructs dislocation glide. Industrially, grain boundary strengthening is favored for cost-effective, large-scale production of durable materials, while precipitation hardening is essential in high-performance sectors like aerospace and automotive manufacturing requiring optimized strength-to-weight ratios.

Grain boundary strengthening Infographic

libterm.com

libterm.com