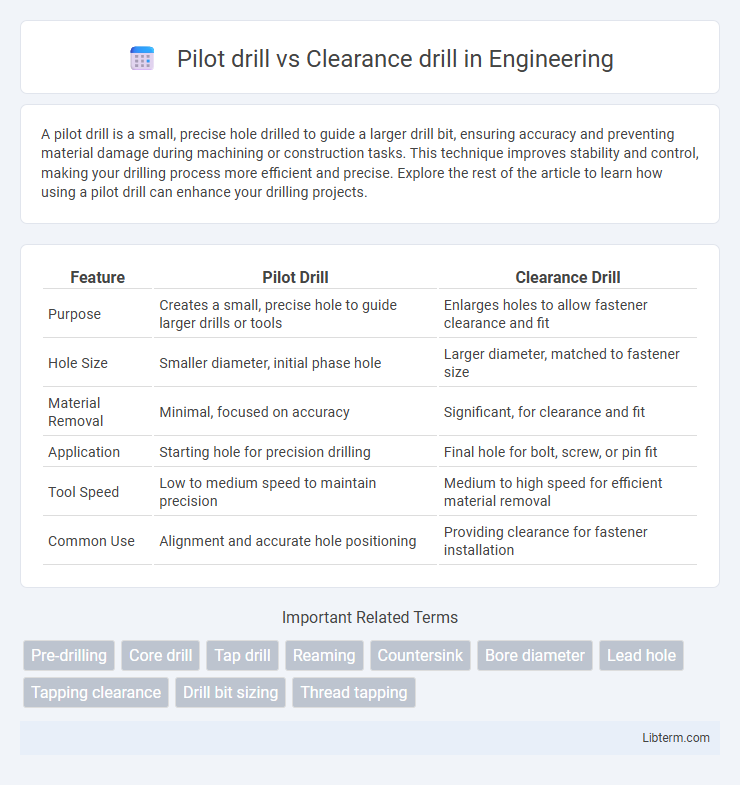

A pilot drill is a small, precise hole drilled to guide a larger drill bit, ensuring accuracy and preventing material damage during machining or construction tasks. This technique improves stability and control, making your drilling process more efficient and precise. Explore the rest of the article to learn how using a pilot drill can enhance your drilling projects.

Table of Comparison

| Feature | Pilot Drill | Clearance Drill |

|---|---|---|

| Purpose | Creates a small, precise hole to guide larger drills or tools | Enlarges holes to allow fastener clearance and fit |

| Hole Size | Smaller diameter, initial phase hole | Larger diameter, matched to fastener size |

| Material Removal | Minimal, focused on accuracy | Significant, for clearance and fit |

| Application | Starting hole for precision drilling | Final hole for bolt, screw, or pin fit |

| Tool Speed | Low to medium speed to maintain precision | Medium to high speed for efficient material removal |

| Common Use | Alignment and accurate hole positioning | Providing clearance for fastener installation |

Introduction to Pilot Drill and Clearance Drill

Pilot drills are small diameter drills used to create initial guide holes in metalwork or wood, ensuring precision and alignment for subsequent drilling operations. Clearance drills are larger diameter drills designed to enlarge the pilot hole to the required final size, allowing bolts or screws to pass through without threading. Both drills are essential in manufacturing and construction for accurate hole preparation and securing fasteners.

Defining Pilot Drill: Purpose and Applications

A pilot drill is a small-diameter drill bit used to create a precise initial hole guiding larger drills during subsequent drilling processes, ensuring accuracy and reducing material stress. Its primary purpose is to set an exact position and depth for the clearance drill, which enlarges the hole to the final required size for fasteners or components. Pilot drills are commonly applied in metalworking, woodworking, and manufacturing industries where precision hole placement is critical.

Understanding Clearance Drill: Usage and Benefits

Clearance drills are used to expand existing pilot holes, improving hole accuracy and reducing friction during fastener insertion, which enhances joint strength and consistency. These drills remove material around the pilot hole to create precise clearance for screws or bolts, preventing binding and ensuring smooth assembly in metalworking and woodworking applications. Proper use of clearance drills leads to better alignment, reduced material stress, and increased overall structural integrity.

Key Differences Between Pilot and Clearance Drills

Pilot drill sizes are smaller and used to create an initial hole that guides the subsequent larger clearance drill, ensuring precision in hole alignment. Clearance drills are larger in diameter, designed to allow fasteners or bolts to pass through without threading, providing proper clearance and fit. The main difference lies in their purpose: pilot drills set the accurate location for drilling, while clearance drills ensure the hole is enlarged for assembly components.

Material Compatibility: Pilot Drill vs Clearance Drill

Pilot drills are designed to create precise guide holes in various materials such as wood, metal, and plastic, ensuring accurate alignment and reducing material stress. Clearance drills, in contrast, are sized slightly larger to allow fastener shafts to pass through without contact, preventing material deformation and maintaining joint integrity. Selecting the appropriate drill type based on material compatibility optimizes hole quality and enhances overall assembly performance.

Steps in Using a Pilot Drill

Using a pilot drill involves selecting a small-diameter drill bit to create an initial guiding hole, ensuring precise alignment for subsequent larger drills and preventing drill bit wandering. The process begins by marking the drilling spot, securing the workpiece, and starting the pilot drill at a controlled speed with steady pressure to establish an accurate hole. After the pilot hole is confirmed, clearance drills are utilized to enlarge the hole to the final diameter, maintaining hole precision and structural integrity.

Steps in Using a Clearance Drill

Using a clearance drill involves several key steps: begin by selecting a drill bit that matches the bolt or screw diameter to ensure proper hole sizing; securely clamp the workpiece to prevent movement during drilling; start with a pilot drill to create an accurate guide hole, then switch to the clearance drill bit to enlarge the hole slightly, allowing the fastener to pass through freely without threading into the material; maintain steady drill speed and pressure for clean hole edges and accurate alignment; finish by deburring the hole to remove sharp edges and ensure smooth assembly. This process optimizes fit, fastening strength, and workpiece integrity in assembly operations.

Common Mistakes with Each Drill Type

Pilot drills often lead to common mistakes such as misalignment and incorrect hole depth, causing inaccurate pilot holes that compromise final drilling accuracy. Clearance drills frequently suffer from issues like oversizing holes or insufficient hole deburring, resulting in poor fit and increased wear of fasteners. Both drill types require precise calibration and technique to avoid errors that affect assembly quality and structural integrity.

Best Practices for Choosing Between Pilot and Clearance Drills

Selecting the appropriate drill size is critical for ensuring accurate hole dimensions and optimal fit during machining processes. Pilot drills, typically smaller, guide the final drill bit to prevent wandering and reduce material stress in concentrated areas, making them ideal for precise hole location in thicker or hard metals. Clearance drills, slightly larger than the fastener, facilitate smooth bolt or screw insertion by creating the necessary space between the hole and the fastener, thus preventing thread damage and ensuring proper alignment in assembly applications.

Conclusion: Selecting the Right Drill for the Task

Choosing the right drill depends on the specific requirements of the project, where pilot drills are ideal for creating precise starter holes that guide larger drill bits, ensuring accuracy and preventing material damage. Clearance drills are essential when a hole must allow a fastener or bolt to pass freely without threading into the material, facilitating proper assembly and bolt alignment. Understanding the distinct functions and applications of pilot and clearance drills optimizes drilling efficiency and structural integrity in manufacturing and construction tasks.

Pilot drill Infographic

libterm.com

libterm.com