General 3D technology revolutionizes how we visualize and interact with digital content, transforming industries from gaming to medical imaging. Its applications extend into education, design, and entertainment, offering immersive experiences and precise modeling capabilities. Explore the full article to discover how General 3D can enhance your projects and creativity.

Table of Comparison

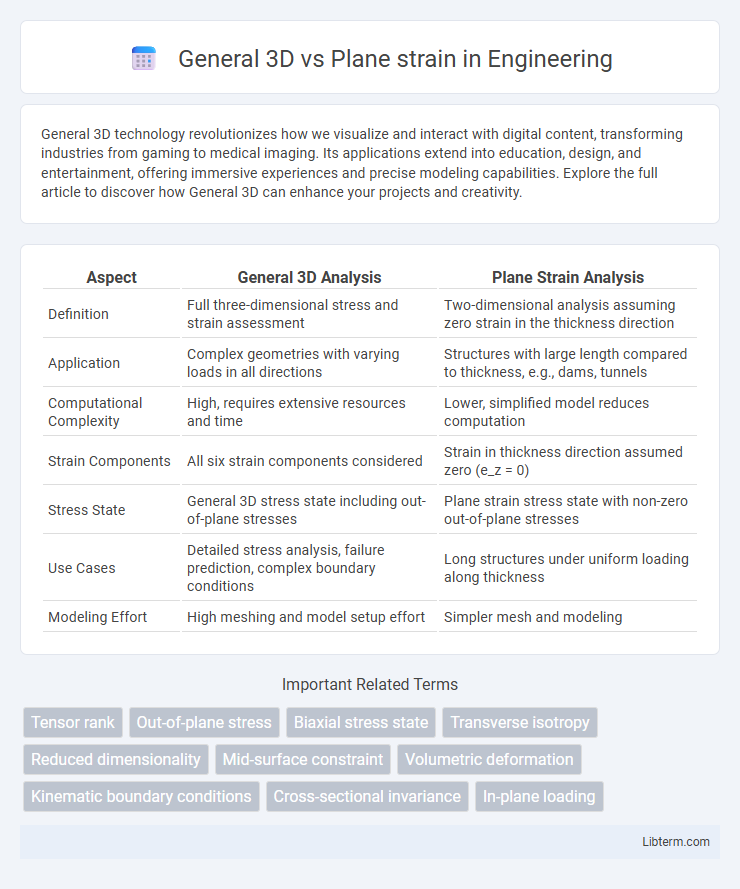

| Aspect | General 3D Analysis | Plane Strain Analysis |

|---|---|---|

| Definition | Full three-dimensional stress and strain assessment | Two-dimensional analysis assuming zero strain in the thickness direction |

| Application | Complex geometries with varying loads in all directions | Structures with large length compared to thickness, e.g., dams, tunnels |

| Computational Complexity | High, requires extensive resources and time | Lower, simplified model reduces computation |

| Strain Components | All six strain components considered | Strain in thickness direction assumed zero (e_z = 0) |

| Stress State | General 3D stress state including out-of-plane stresses | Plane strain stress state with non-zero out-of-plane stresses |

| Use Cases | Detailed stress analysis, failure prediction, complex boundary conditions | Long structures under uniform loading along thickness |

| Modeling Effort | High meshing and model setup effort | Simpler mesh and modeling |

Introduction to 3D and Plane Strain Analysis

General 3D analysis evaluates stresses and strains in all three spatial dimensions, capturing complex geometries and loading conditions in structures with significant out-of-plane effects. Plane strain analysis assumes zero strain in the thickness direction, typically applied to long structures where deformation across thickness is negligible, simplifying modeling and computational effort. Understanding the distinction between 3D and plane strain is crucial for selecting appropriate methods in finite element analysis, ensuring accuracy and efficiency based on the problem's dimensional characteristics.

Fundamental Concepts of 3D Stress and Strain

General 3D stress and strain analysis considers all six components of stress and strain tensors, capturing the complete state of stress in three-dimensional bodies, essential for accurately modeling complex loading conditions. Plane strain conditions simplify the problem by assuming zero strain in one principal direction, typically applicable in long structures where deformation perpendicular to the cross-section is negligible. Understanding the fundamental difference between full 3D stress tensors and plane strain approximations is critical for selecting appropriate boundary conditions and ensuring precise predictions in structural, geotechnical, and material deformation analyses.

Defining Plane Strain: Assumptions and Applications

Plane strain assumes deformation occurs primarily in two dimensions, with negligible strain in the third dimension, making it ideal for modeling long structures where thickness remains constant. This simplification reduces computational complexity while accurately representing stress and strain distributions in applications such as tunnels, dams, and deep beams. In contrast, general 3D analysis captures full spatial variation, essential for components with significant out-of-plane deformation or complex geometries.

Key Differences Between General 3D and Plane Strain

General 3D analysis considers deformation and stress in all three spatial dimensions, capturing complex geometries and boundary conditions where strain varies in every direction, while plane strain assumes no strain in the out-of-plane direction, simplifying problems that are long in one dimension compared to the other two. Plane strain is commonly applied in structures like tunnels and dams, where thickness is large relative to the in-plane dimensions, whereas General 3D models are essential for detailed stress evaluations in components with intricate 3D features or localized effects. The choice between General 3D and Plane strain directly affects computational complexity, required material models, and the accuracy of stress-strain predictions in engineering simulations.

Mathematical Formulation: 3D vs Plane Strain

The mathematical formulation of general 3D elasticity involves solving stress and strain tensors in all three spatial dimensions, requiring the consideration of six independent strain components and six corresponding stress components. Plane strain simplifies this by assuming strain in one direction (usually the thickness direction) is zero, reducing the problem to four nonzero strain components and associated stress components, which leads to a smaller system of partial differential equations. This reduction streamlines computational complexity while maintaining accuracy for long structures with constrained deformation in the out-of-plane direction.

Typical Engineering Applications

General 3D analysis is essential in complex structures like aerospace components, automotive crash simulations, and biomechanical implants where stress and deformation occur in multiple directions simultaneously. Plane strain models are typically used in geotechnical engineering, such as tunnel walls and dam foundations, where the strain in one direction is negligible due to the geometry's extent. Engineers select General 3D for detailed localized stress predictions and Plane strain for large-scale problems with uniform strain conditions along one axis.

Advantages and Limitations of General 3D Analysis

General 3D analysis provides a comprehensive understanding of complex mechanical behaviors by accounting for variations in all three spatial dimensions, enabling accurate modeling of stress, strain, and deformation in irregular geometries and heterogeneous materials. It captures edge effects and out-of-plane stresses that plane strain assumptions ignore, making it ideal for detailed analysis where thickness effects and stress gradients across the thickness are significant. However, General 3D analysis demands high computational resources and longer simulation times, making it less practical for large-scale or simplified problems where plane strain assumptions offer efficient and sufficiently accurate approximations.

Advantages and Limitations of Plane Strain Analysis

Plane strain analysis simplifies complex 3D stress states by assuming zero strain in one direction, making it highly effective for modeling long structures like tunnels, dams, and thick walls where deformation is predominantly two-dimensional. This method offers computational efficiency and reduced processing time compared to full 3D simulations, enabling quicker assessments of stress and displacement fields under constrained deformation conditions. However, plane strain analysis is limited in scenarios with significant out-of-plane stresses or strains, as it cannot capture three-dimensional effects such as localized bending or twisting, potentially leading to less accurate predictions for components with complex geometries or loadings.

Selection Criteria: When to Use 3D or Plane Strain

General 3D analysis is essential for modeling complex geometries, localized stress concentrations, and scenarios involving multi-directional loading where out-of-plane effects cannot be neglected. Plane strain assumptions are suitable for long structures with uniform cross-sections subjected to loadings predominantly in two dimensions, minimizing computational effort while maintaining accuracy. Selecting between 3D and plane strain depends on the geometry scale, loading conditions, and the need to capture three-dimensional stress gradients accurately.

Summary and Future Perspectives

General 3D analysis captures complex stress and deformation states in structures more accurately than plane strain models, which assume deformation constraints in one dimension, limiting their application to specific scenarios such as long, prismatic bodies. Future perspectives emphasize integrating advanced computational methods and machine learning algorithms to enhance 3D modeling efficiency and predictive accuracy, enabling more precise simulations of real-world engineering problems. Continued development in high-performance computing and adaptive meshing techniques will further improve the fidelity and applicability of general 3D analyses in diverse industries.

General 3D Infographic

libterm.com

libterm.com