Plug welding is a technique used to join two metal pieces by filling a hole in the top metal layer with weld material, forming a strong bond with the underlying metal. This method is commonly employed in automotive and metal fabrication industries for creating durable joints without access to both sides of the workpieces. Explore the rest of the article to understand how plug welding can enhance your metalworking projects.

Table of Comparison

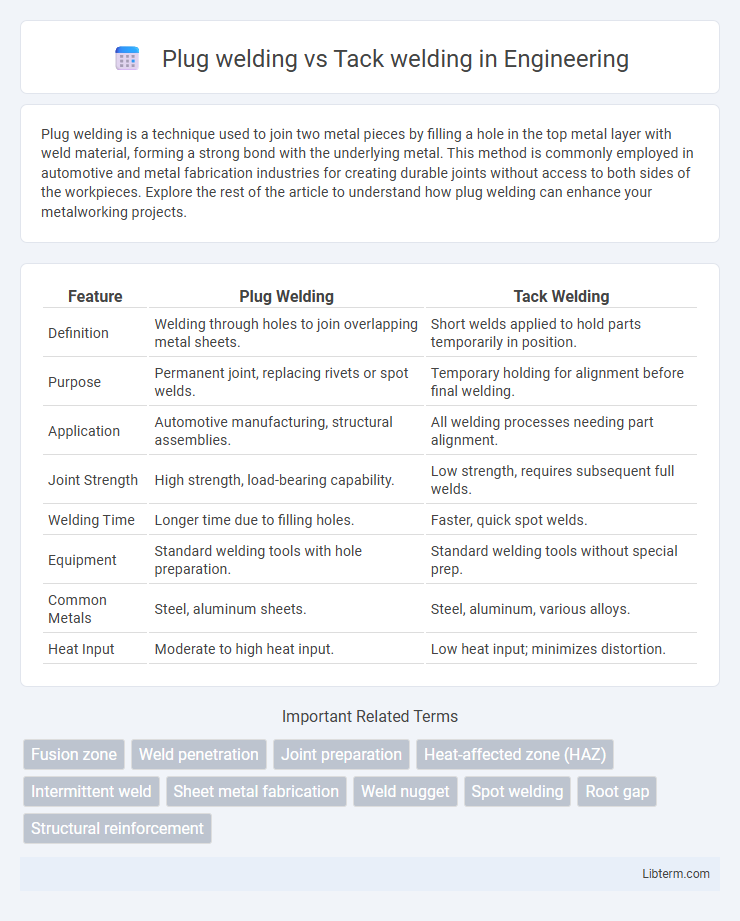

| Feature | Plug Welding | Tack Welding |

|---|---|---|

| Definition | Welding through holes to join overlapping metal sheets. | Short welds applied to hold parts temporarily in position. |

| Purpose | Permanent joint, replacing rivets or spot welds. | Temporary holding for alignment before final welding. |

| Application | Automotive manufacturing, structural assemblies. | All welding processes needing part alignment. |

| Joint Strength | High strength, load-bearing capability. | Low strength, requires subsequent full welds. |

| Welding Time | Longer time due to filling holes. | Faster, quick spot welds. |

| Equipment | Standard welding tools with hole preparation. | Standard welding tools without special prep. |

| Common Metals | Steel, aluminum sheets. | Steel, aluminum, various alloys. |

| Heat Input | Moderate to high heat input. | Low heat input; minimizes distortion. |

Introduction to Plug Welding and Tack Welding

Plug welding involves filling a hole in one metal piece with weld material to join it to another underlying metal, providing strong, permanent joints often used in automotive and structural applications. Tack welding is a technique where small welds temporarily hold components in place before completing a full weld, ensuring alignment and stability during fabrication. Both methods serve distinct roles in metal joining, with plug welding offering structural integrity and tack welding enabling precise assembly.

What is Plug Welding?

Plug welding is a process where holes in one metal piece are filled with weld material to fuse it to another piece beneath. This technique creates a strong, solid joint by penetrating and bonding the overlapping metals through the plug's weld pool. Commonly used in sheet metal fabrication and automotive manufacturing, plug welding provides structural integrity and resistance to shear forces.

What is Tack Welding?

Tack welding is a temporary welding technique used to hold components in place before performing the final welds, ensuring proper alignment and fit-up. It involves applying small, discrete welds at intervals along the joint, which minimizes distortion and secures parts to prevent movement during the welding process. This method is essential in fabrication and assembly for maintaining structural integrity before completing full welds, contrasting with plug welding, which fills holes with weld metal to join overlapping parts.

Key Differences Between Plug Welding and Tack Welding

Plug welding involves filling a hole in one metal piece to join it with another, creating a strong and permanent bond primarily used for thicker materials. Tack welding uses small weld spots to temporarily hold components in place before final welding, offering quick alignment without structural strength. Key differences include the permanence and strength of the weld, with plug welding providing full penetration and tack welding serving as a temporary fixture.

Advantages of Plug Welding

Plug welding provides stronger and more secure joints compared to tack welding, making it ideal for load-bearing applications in automotive and structural industries. This method offers better resistance to shear forces and improves the overall integrity of the welded assembly, reducing the risk of joint failure under stress. Plug welding also allows for improved penetration and fusion between overlapping metal sheets, enhancing durability and longevity in welded structures.

Advantages of Tack Welding

Tack welding offers precise control for securing components temporarily, allowing for easy adjustments and alignment before final welding, which reduces the risk of distortion. It requires less heat input compared to plug welding, minimizing thermal stress and warping in delicate or thin materials. Tack welding also enables faster assembly processes, improving efficiency in production lines and repair work where temporary holding is sufficient before full welds are applied.

Common Applications of Plug Welding

Plug welding is commonly used in automotive manufacturing to join sheet metal components, providing strong, durable bonds in areas such as wheel wells and floor pans. It is also extensively applied in heavy equipment fabrication for assembling thick metal plates where high structural integrity is required. In contrast, tack welding primarily serves as a temporary method to hold parts in position before final welding.

Common Uses of Tack Welding

Tack welding is commonly used to temporarily hold metal pieces in proper alignment before final welding, making it essential in fabrication, automotive repair, and construction applications where precise fit-up is crucial. This method ensures stability and prevents distortion during the welding process, particularly in assembling large structures or components with multiple joints. Unlike plug welding, which fills holes to join overlapping metals, tack welding provides small, strategically placed welds to maintain position without the need for full penetration.

Factors to Consider When Choosing Plug vs Tack Welding

Choosing between plug welding and tack welding depends on factors such as joint strength requirements, metal thickness, and application type. Plug welding provides a stronger, more permanent bond suitable for load-bearing structures, while tack welding offers temporary positioning or alignment during assembly. Consider weld accessibility, heat distortion potential, and overall project durability when selecting the appropriate welding method.

Conclusion: Which Welding Method is Right for Your Project?

Plug welding offers a stronger, more permanent bond ideal for structural applications requiring durability and load-bearing capacity, while tack welding provides quick, temporary joints useful for positioning and alignment during assembly. Choosing between plug and tack welding depends on project requirements, such as strength needs, welding time, and metal thickness. For long-term, high-stress connections, plug welding is more suitable, whereas tack welding is efficient for initial fixture or non-critical parts.

Plug welding Infographic

libterm.com

libterm.com