Bang-bang control is a feedback control strategy that switches abruptly between two states, typically fully on or fully off, to regulate a system's output. This method offers simplicity and fast response, making it ideal for applications like thermostats and motor control where precise modulation is unnecessary. Dive into the article to explore how bang-bang control can optimize your system's performance effectively.

Table of Comparison

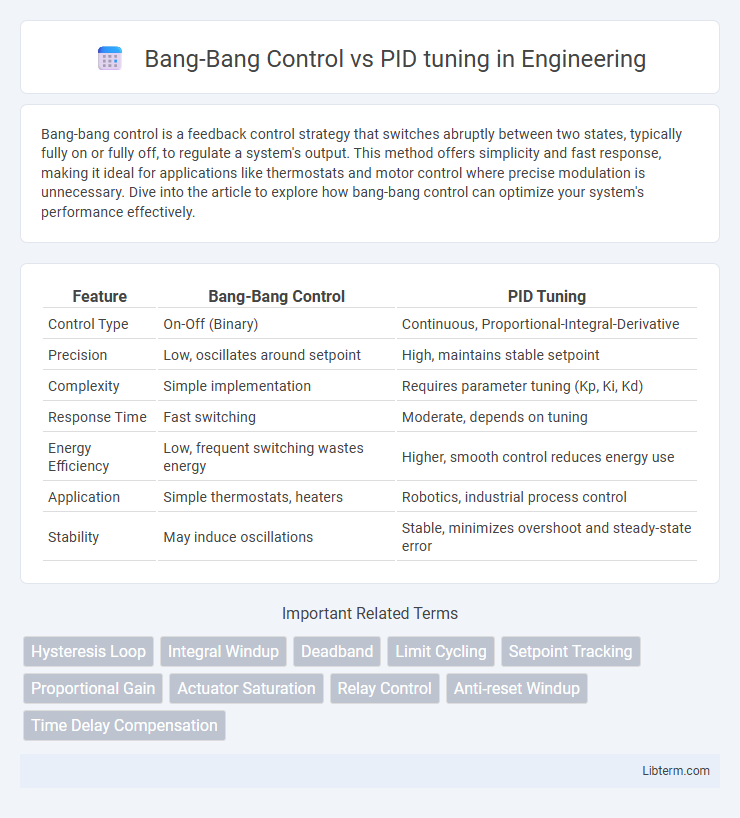

| Feature | Bang-Bang Control | PID Tuning |

|---|---|---|

| Control Type | On-Off (Binary) | Continuous, Proportional-Integral-Derivative |

| Precision | Low, oscillates around setpoint | High, maintains stable setpoint |

| Complexity | Simple implementation | Requires parameter tuning (Kp, Ki, Kd) |

| Response Time | Fast switching | Moderate, depends on tuning |

| Energy Efficiency | Low, frequent switching wastes energy | Higher, smooth control reduces energy use |

| Application | Simple thermostats, heaters | Robotics, industrial process control |

| Stability | May induce oscillations | Stable, minimizes overshoot and steady-state error |

Introduction to Bang-Bang Control and PID Tuning

Bang-Bang control operates on a simple on/off mechanism, switching outputs abruptly based on predefined thresholds, making it ideal for systems requiring rapid response without precision. PID tuning involves adjusting proportional, integral, and derivative parameters to achieve precise control, minimizing error through continuous feedback and smooth output modulation. Understanding the fundamental differences between Bang-Bang control's binary action and PID's continuous modulation is crucial for selecting the appropriate control strategy in automation and process control applications.

Fundamental Differences Between Bang-Bang and PID Controllers

Bang-Bang control operates on a simple on-off mechanism, switching output fully on or off based on error thresholds, whereas PID controllers use proportional, integral, and derivative terms to provide continuous and smooth control signals. Bang-Bang controllers are suitable for systems needing rapid switching with minimal computational resources, but they often cause oscillations and lack precision. PID tuning involves adjusting parameters to minimize steady-state error, overshoot, and settling time, delivering stability and accuracy unmatched by the binary nature of Bang-Bang control.

Principles of Operation: How Bang-Bang Control Works

Bang-Bang Control operates by switching the control output abruptly between two states, typically ON and OFF, to maintain a process variable within a set threshold. This binary approach contrasts with PID tuning, which continuously adjusts the output based on proportional, integral, and derivative calculations to minimize error. Bang-Bang Control relies on simple hysteresis to prevent rapid switching, making it suitable for systems where precise control is less critical and response speed is paramount.

Principles of Operation: How PID Tuning Works

PID tuning optimizes the proportional, integral, and derivative parameters to minimize error by continuously adjusting process outputs based on feedback, ensuring smooth and precise control. The proportional component addresses the current error, the integral tackles accumulated past errors, and the derivative predicts future trends to dampen oscillations. Unlike Bang-Bang control, which switches abruptly between on and off states, PID tuning enables gradual and stable system response by calculating control signals proportionate to the deviation.

Advantages of Bang-Bang Control Systems

Bang-Bang control systems offer simplicity and cost-effectiveness due to their straightforward on-off operation, eliminating the need for complex sensor feedback and continuous calibration. They provide rapid response times and robustness in systems with binary states, making them ideal for applications like thermostats and basic motor controls. Their minimal computational requirements allow for easy implementation in low-power or resource-constrained environments.

Advantages of PID Controllers

PID controllers offer precise and stable control by continuously adjusting the control signal based on proportional, integral, and derivative terms, which reduces overshoot and steady-state error. Their adaptability to varying system dynamics makes them suitable for complex industrial processes requiring fine-tuned regulation. Compared to Bang-Bang control, PID controllers provide smoother operation and enhanced accuracy, improving overall system performance and efficiency.

Common Applications of Bang-Bang vs PID Control

Bang-Bang control is commonly used in simple systems requiring on/off regulation such as thermostats, basic motor controls, and household appliances where immediate switching between states is effective. PID control finds extensive application in complex industrial processes like chemical reactors, robotic arms, and HVAC systems that demand precise, continuous adjustments to maintain stability and optimal performance. The choice between Bang-Bang and PID tuning depends largely on system complexity, accuracy requirements, and the nature of the controlled process.

Limitations and Challenges of Each Method

Bang-Bang Control faces significant limitations due to its on-off nature, causing oscillations and wear in mechanical components without providing fine control accuracy. PID tuning challenges include selecting appropriate proportional, integral, and derivative gains to avoid instability, overshooting, or sluggish response, which requires expert knowledge and iterative testing. Both methods struggle with non-linear systems and external disturbances, but PID offers better adaptability at the cost of increased complexity and sensitivity to parameter tuning errors.

Criteria for Choosing Between Bang-Bang and PID

Bang-Bang control is preferred for simple, on/off systems where rapid switching between states is sufficient, such as thermostats or safety devices, due to its straightforward implementation and low computational requirements. PID tuning is ideal for applications requiring precise, continuous control and minimized overshoot, oscillation, or steady-state error, making it suitable for processes like motor speed regulation or chemical mixing. The decision hinges on system dynamics, desired accuracy, and the complexity of the control task, with Bang-Bang favored for binary states and PID for nuanced, proportional response.

Future Trends in Control System Design

Future trends in control system design emphasize the integration of adaptive PID tuning algorithms with machine learning techniques to enhance process stability and reduce overshoot. Bang-Bang control is increasingly applied in conjunction with smart sensors and IoT devices to manage systems requiring rapid switching and minimal computational overhead. Advances in hybrid control strategies are expected to leverage the robustness of Bang-Bang control and the precision of PID tuning for optimized industrial automation and autonomous systems.

Bang-Bang Control Infographic

libterm.com

libterm.com