Binder Jetting revolutionizes 3D printing by using a liquid binding agent to fuse powder materials layer by layer, enabling fast production of complex geometries with minimal waste. This additive manufacturing process supports a wide range of materials, including metals, ceramics, and sand, making it ideal for both prototyping and low-volume manufacturing. Discover how Binder Jetting can transform Your manufacturing capabilities by exploring its innovative applications and benefits in the rest of the article.

Table of Comparison

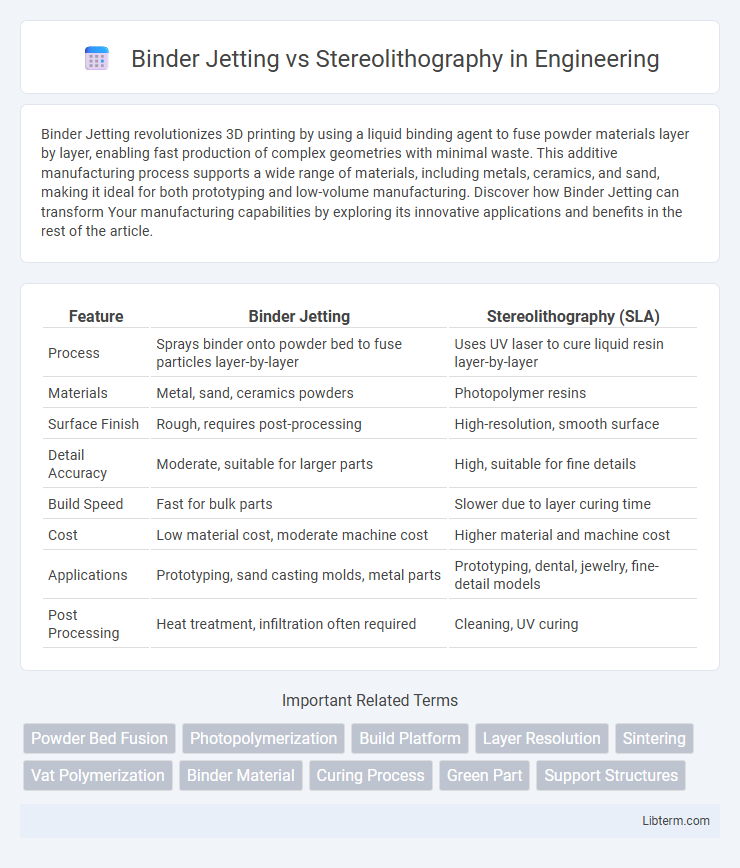

| Feature | Binder Jetting | Stereolithography (SLA) |

|---|---|---|

| Process | Sprays binder onto powder bed to fuse particles layer-by-layer | Uses UV laser to cure liquid resin layer-by-layer |

| Materials | Metal, sand, ceramics powders | Photopolymer resins |

| Surface Finish | Rough, requires post-processing | High-resolution, smooth surface |

| Detail Accuracy | Moderate, suitable for larger parts | High, suitable for fine details |

| Build Speed | Fast for bulk parts | Slower due to layer curing time |

| Cost | Low material cost, moderate machine cost | Higher material and machine cost |

| Applications | Prototyping, sand casting molds, metal parts | Prototyping, dental, jewelry, fine-detail models |

| Post Processing | Heat treatment, infiltration often required | Cleaning, UV curing |

Overview of Binder Jetting and Stereolithography

Binder Jetting employs a liquid binding agent selectively deposited onto a powder bed, enabling rapid production of full-color, complex metal, ceramic, or sand parts with minimal heat-induced distortion. Stereolithography uses a laser to cure liquid photopolymer resin layer by layer, achieving high-resolution and smooth-surfaced prototypes primarily suited for precise plastics and intricate geometries. Both technologies serve distinct manufacturing needs, with Binder Jetting excelling in metal and sand applications, while Stereolithography offers superior detail for polymer-based parts.

Fundamental Principles and Processes

Binder Jetting employs a liquid binding agent selectively deposited onto a powder bed, layer by layer, creating complex geometries without heat-driven fusion. Stereolithography (SLA) utilizes a UV laser to cure liquid photopolymer resin, solidifying each layer through a precise photopolymerization process. While Binder Jetting builds parts through powder bonding and subsequent sintering, SLA achieves high-resolution details via controlled resin solidification.

Material Compatibility and Selection

Binder Jetting offers broad material compatibility, including metals, ceramics, and sand, enabling versatile applications in aerospace, automotive, and casting industries. Stereolithography is primarily compatible with photopolymer resins, which provide high-detail, smooth surface finishes ideal for prototypes, dental, and jewelry applications. Material selection in Binder Jetting depends on the powder type and binder, while Stereolithography requires selecting specific resin formulations tailored for mechanical properties and curing speed.

Precision and Surface Finish Comparison

Binder Jetting delivers moderate precision with layer thickness typically around 50 to 100 microns, producing parts with a rougher surface finish requiring post-processing. Stereolithography (SLA) excels in precision, achieving layer resolutions as fine as 25 microns, resulting in smooth surfaces ideal for detailed prototypes and cosmetic parts. The inherent differences in these technologies mean SLA generally outperforms Binder Jetting in both dimensional accuracy and surface quality.

Build Speed and Efficiency

Binder Jetting offers significantly faster build speeds by simultaneously depositing binder across entire layers, making it ideal for high-volume production. Stereolithography (SLA) involves slower, precise laser curing of photopolymer resin layer by layer, which enhances detail but reduces throughput. Efficiency in Binder Jetting is higher for metal and sand parts due to minimal post-processing, whereas SLA demands extensive cleaning and curing, impacting overall production time.

Design Flexibility and Limitations

Binder Jetting offers high design flexibility for producing complex geometries and large-scale parts but struggles with fine details and smooth surface finishes compared to Stereolithography (SLA). Stereolithography excels in detail resolution and smooth surfaces, enabling intricate designs with tight tolerances, yet it is limited to smaller build volumes and less suitable for producing robust, functional prototypes. Both technologies require design adjustments: Binder Jetting demands consideration for powder support and post-processing, while SLA designs must accommodate resin viscosity and potential shrinkage.

Cost Analysis of Both Technologies

Binder Jetting offers a cost-effective solution for large-scale metal and sand parts due to lower material expenses and faster print speeds, while Stereolithography incurs higher costs driven by expensive resin materials and slower post-processing times. Maintenance and operational costs are generally lower for Binder Jetting since it requires less energy and simpler support removal compared to the UV curing and resin handling in Stereolithography. Overall, for prototyping and production where cost-efficiency is critical, Binder Jetting provides a financially advantageous option, whereas Stereolithography suits high-detail applications despite its higher price point.

Applications and Industry Use Cases

Binder jetting excels in producing complex metal parts for aerospace and automotive applications, offering cost-effective and scalable manufacturing of functional prototypes and end-use components. Stereolithography (SLA) is widely used in dental, jewelry, and medical industries to create highly detailed resin models with superior surface finish and accuracy. Both technologies support rapid prototyping, but binder jetting's material versatility suits industrial-scale production, whereas SLA prioritizes precision in small-batch, intricate designs.

Advantages and Disadvantages

Binder Jetting offers rapid production and cost-effective printing for large metal or sand parts but often results in lower surface finish quality and mechanical strength compared to Stereolithography. Stereolithography provides superior precision and smooth surface finishes suitable for detailed prototypes, though it is generally slower and less economical for large-scale manufacturing. Both processes require post-processing, but Binder Jetting involves sintering or infiltration, while Stereolithography needs UV curing and cleaning steps.

Future Trends in Additive Manufacturing

Binder Jetting is evolving with advancements in multi-material printing and increased printing speeds, making it suitable for large-scale industrial applications with complex geometries and metal parts production. Stereolithography (SLA) continues to innovate through enhanced resin formulations and ultra-high-resolution printing, enabling intricate prototypes and functional parts for biomedical and aerospace industries. Future trends in additive manufacturing emphasize hybrid manufacturing systems combining Binder Jetting and SLA for optimized precision, speed, and material properties, driving customization and mass production capabilities.

Binder Jetting Infographic

libterm.com

libterm.com