A flexible shaft transmits rotary motion between two points that are not aligned, allowing for smooth operation in tight or complex spaces. Its versatility suits various applications, from power tools to medical devices, ensuring efficiency and precision. Explore the rest of this article to understand how a flexible shaft can enhance your mechanical solutions.

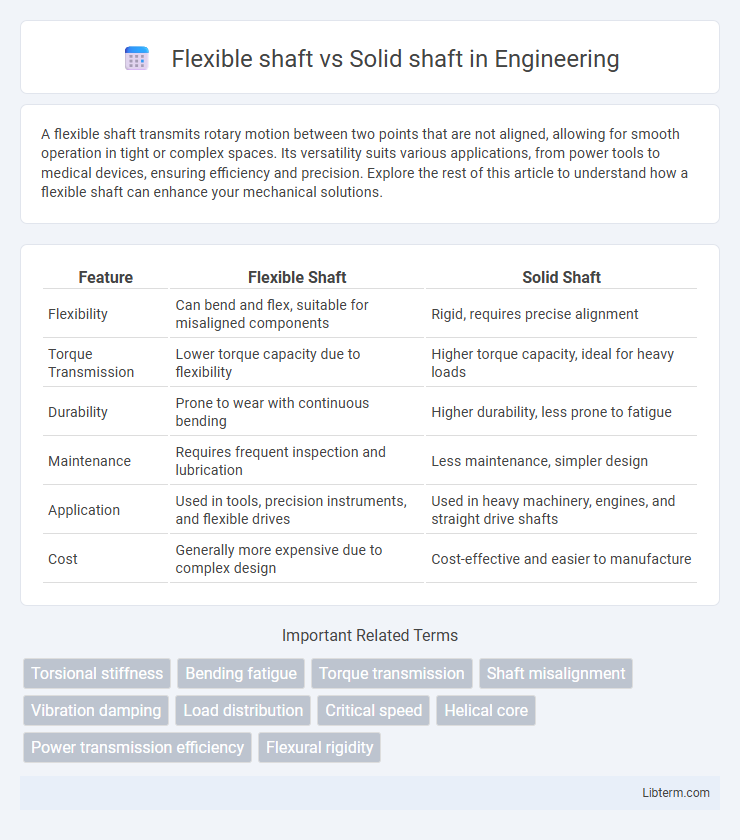

Table of Comparison

| Feature | Flexible Shaft | Solid Shaft |

|---|---|---|

| Flexibility | Can bend and flex, suitable for misaligned components | Rigid, requires precise alignment |

| Torque Transmission | Lower torque capacity due to flexibility | Higher torque capacity, ideal for heavy loads |

| Durability | Prone to wear with continuous bending | Higher durability, less prone to fatigue |

| Maintenance | Requires frequent inspection and lubrication | Less maintenance, simpler design |

| Application | Used in tools, precision instruments, and flexible drives | Used in heavy machinery, engines, and straight drive shafts |

| Cost | Generally more expensive due to complex design | Cost-effective and easier to manufacture |

Introduction to Flexible and Solid Shafts

Flexible shafts consist of a core wire or coil designed to transmit rotary motion through bends and curves, allowing for versatile applications where rigid alignment is not feasible. Solid shafts are rigid mechanical elements typically used to transmit torque and rotation in straight-line configurations, providing high strength and resistance to torsional deformation. The choice between flexible and solid shafts depends on the need for adaptability versus rigidity in mechanical power transmission systems.

Key Differences Between Flexible and Solid Shafts

Flexible shafts offer greater adaptability by allowing torque transmission through curves and bends, making them ideal for applications requiring maneuverability, whereas solid shafts provide higher strength and rigidity suited for direct power transmission. Material composition and design influence their torque capacity, with solid shafts generally supporting higher loads due to their unbroken structure, while flexible shafts incorporate inner cores and outer casings to maintain flexibility. Maintenance requirements differ as flexible shafts may require more frequent inspection for wear and fatigue, while solid shafts demand monitoring for alignment and stress-related fractures.

Construction and Material Composition

Flexible shafts consist of tightly wound helical wire strands, typically made from high-grade steel or stainless steel, allowing them to bend while transmitting torque smoothly. Solid shafts are manufactured from a single, continuous piece of metal, commonly carbon steel or alloy steel, offering higher torsional rigidity and strength. The construction differences directly influence their flexibility, durability, and suitability for various mechanical applications.

Flexibility and Motion Capabilities

Flexible shafts offer superior flexibility, allowing for the transmission of rotary motion around obstacles and through curved paths, making them ideal for applications requiring maneuverability. Solid shafts provide high torque transmission with minimal torsional deflection but lack the adaptability to navigate complex motion routes. The choice between flexible and solid shafts hinges on the need for movement versatility versus torque rigidity in mechanical systems.

Strength and Durability Comparison

Flexible shafts offer superior bending endurance and resistance to torsional stress, making them ideal for applications requiring frequent movement and intricate maneuvering. Solid shafts provide greater overall strength and rigidity, delivering higher load-bearing capacity and durability in heavy-duty machinery where minimal deformation is critical. The choice between flexible and solid shafts depends on balancing the need for flexibility against maximum strength and long-term durability in specific operational conditions.

Efficiency in Power Transmission

Flexible shafts offer enhanced efficiency in power transmission by allowing for smooth torque transfer in applications with misalignment or complex routing, reducing energy losses caused by vibration and bending. Solid shafts provide higher efficiency in straightforward, rigid alignments due to their minimal flex and lower internal friction, which maximizes torque delivery and reduces maintenance needs. Selection between flexible and solid shafts depends on operational conditions, with flexible shafts excelling in dynamic environments and solid shafts optimizing efficiency in stable, linear power transmission setups.

Typical Applications and Industries

Flexible shafts excel in applications requiring complex routing and vibration absorption, commonly used in dental equipment, power tools, and robotics for precise torque transmission. Solid shafts are preferred in automotive drivetrains, industrial machinery, and construction equipment where high torque capacity and rigidity are critical. Industries such as aerospace, medical devices, and manufacturing often select flexible shafts for adaptability, while solid shafts dominate heavy-duty and high-load environments.

Maintenance and Longevity

Flexible shafts typically require more frequent maintenance due to their moving internal components and susceptibility to wear, including lubrication and inspection for bends or cracks. Solid shafts offer greater durability and longevity with lower maintenance demands because their rigid construction resists deformation and reduces the risk of mechanical failure. Proper alignment and regular checks are essential for both types to maximize service life and operational efficiency.

Cost Considerations

Flexible shafts generally incur higher initial costs due to complex manufacturing and specialized materials, while solid shafts are more cost-effective to produce because of simpler design and common material use. Maintenance expenses for flexible shafts can increase over time due to wear and potential failure in dynamic applications, whereas solid shafts typically demand less frequent maintenance, resulting in lower long-term costs. Choosing between them depends on balancing initial investment against lifecycle expenses based on application requirements.

Choosing the Right Shaft for Your Needs

Choosing the right shaft depends on the application's flexibility requirements and torque transmission. Flexible shafts offer excellent adaptability for transmitting rotary motion around bends or in confined spaces, making them ideal for precision tools and automotive controls. Solid shafts provide superior strength and rigidity, suitable for high-torque and heavy-duty industrial machinery where durability and minimal deflection are critical.

Flexible shaft Infographic

libterm.com

libterm.com