Phase Change Materials (PCMs) store and release thermal energy by changing their physical state, typically from solid to liquid and vice versa. This capability makes them highly efficient for temperature regulation in building materials, electronics cooling, and thermal energy storage systems. Discover how PCMs can enhance your energy efficiency and explore their diverse applications in the rest of this article.

Table of Comparison

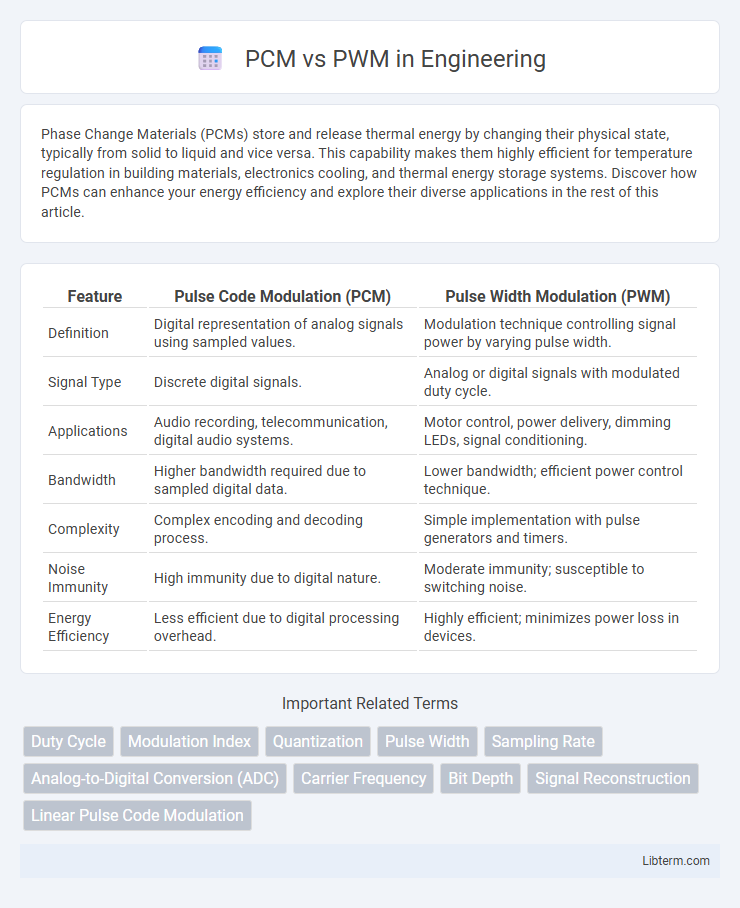

| Feature | Pulse Code Modulation (PCM) | Pulse Width Modulation (PWM) |

|---|---|---|

| Definition | Digital representation of analog signals using sampled values. | Modulation technique controlling signal power by varying pulse width. |

| Signal Type | Discrete digital signals. | Analog or digital signals with modulated duty cycle. |

| Applications | Audio recording, telecommunication, digital audio systems. | Motor control, power delivery, dimming LEDs, signal conditioning. |

| Bandwidth | Higher bandwidth required due to sampled digital data. | Lower bandwidth; efficient power control technique. |

| Complexity | Complex encoding and decoding process. | Simple implementation with pulse generators and timers. |

| Noise Immunity | High immunity due to digital nature. | Moderate immunity; susceptible to switching noise. |

| Energy Efficiency | Less efficient due to digital processing overhead. | Highly efficient; minimizes power loss in devices. |

Introduction to PCM and PWM

Pulse Code Modulation (PCM) and Pulse Width Modulation (PWM) are fundamental methods used in digital signal processing and communication. PCM encodes analog signals into a digital bitstream by sampling the amplitude at regular intervals, making it ideal for high-fidelity audio and data transmission. PWM varies the width of digital pulses to represent analog signal levels, commonly applied in motor control and power regulation due to its efficient energy use.

Defining Pulse Code Modulation (PCM)

Pulse Code Modulation (PCM) is a digital representation of analog signals where the amplitude of the continuous signal is sampled at uniform intervals and quantized into a series of binary numbers. This encoding process allows for accurate and noise-resistant transmission of audio, video, and other data over digital communication systems. PCM is widely used in telephony, audio recording, and digital signal processing for its high fidelity and efficient bandwidth utilization.

Understanding Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) controls the power supplied to electrical devices by varying the duty cycle of digital pulses, enabling precise adjustment of voltage and current without energy loss. Unlike Pulse Code Modulation (PCM), which encodes analog signals into a binary form for digital transmission, PWM modulates signal width to regulate output power efficiently. PWM's effectiveness in motor speed control, LED dimming, and power delivery highlights its importance in modern electronics and embedded systems.

Core Differences Between PCM and PWM

Pulse Code Modulation (PCM) encodes analog signals into binary form by sampling amplitude levels at uniform intervals, enabling precise digital representation. Pulse Width Modulation (PWM) controls the power delivered to devices by varying the width of fixed-amplitude pulses within a constant frequency signal. The core difference lies in PCM's digital signal encoding for data transmission and storage, whereas PWM is primarily used for analog signal control through varying pulse durations.

Applications of PCM in Modern Technology

Pulse Code Modulation (PCM) is widely applied in digital telephony, audio recording, and multimedia streaming due to its high fidelity and noise resistance. It is integral in compact disc (CD) technology, Voice over Internet Protocol (VoIP) systems, and digital television broadcasting, enabling reliable and clear data transmission. The robustness of PCM in converting analog signals into digital form makes it essential for modern communication and data storage infrastructures.

Common Uses of PWM Across Industries

Pulse Width Modulation (PWM) is widely used in motor control applications across automotive, industrial automation, and robotics for precise speed and torque management. In telecommunications, PWM serves as a modulation technique for signal encoding and data transmission to enhance communication reliability. PWM also plays a critical role in power electronics, such as inverters and DC-DC converters, improving energy efficiency and thermal performance in renewable energy systems and consumer electronics.

Advantages of PCM Over PWM

Pulse Code Modulation (PCM) offers superior noise immunity and signal integrity compared to Pulse Width Modulation (PWM) due to its digital encoding of analog signals, which reduces distortion and error rates during transmission. PCM facilitates easier error detection and correction, enhancing communication reliability in complex systems such as digital telephony and data networks. The quantization process in PCM also enables more precise signal representation, making it ideal for high-fidelity audio and video applications.

Benefits of PWM Compared to PCM

Pulse Width Modulation (PWM) offers superior energy efficiency and finer control over power delivery compared to Pulse Code Modulation (PCM), making it ideal for applications like motor speed control and dimming LED lights. PWM reduces heat loss by adjusting the duty cycle of the signal rather than varying voltage levels, leading to lower power dissipation and improved device lifespan. Enhanced noise immunity and smoother signal transitions further contribute to PWM's advantage in precision and reliability in electronic and communication systems.

Challenges and Limitations of Both Modulation Techniques

Pulse Code Modulation (PCM) faces challenges such as quantization noise and high bandwidth requirements due to its discrete amplitude representation, making it less efficient for bandwidth-constrained systems. Pulse Width Modulation (PWM) encounters limitations including susceptibility to noise, signal distortion from varying pulse widths, and reduced fidelity in transmitting analog signals. Both techniques require careful trade-offs between complexity, power consumption, and signal integrity in communication and control applications.

Choosing the Right Modulation: PCM or PWM?

Choosing the right modulation between Pulse Code Modulation (PCM) and Pulse Width Modulation (PWM) depends on the application requirements for signal accuracy and bandwidth efficiency. PCM offers precise digital representation, ideal for audio and communication systems needing noise immunity and error correction. PWM excels in power control and motor drive contexts due to its efficient analog control through varying pulse widths.

PCM Infographic

libterm.com

libterm.com