A fracture occurs when a bone breaks due to high impact, stress, or underlying medical conditions, resulting in pain, swelling, and impaired movement. Proper diagnosis and treatment, such as immobilization or surgery, are essential for effective healing and preventing complications. Explore the rest of this article to understand different types of fractures and the best methods for recovery.

Table of Comparison

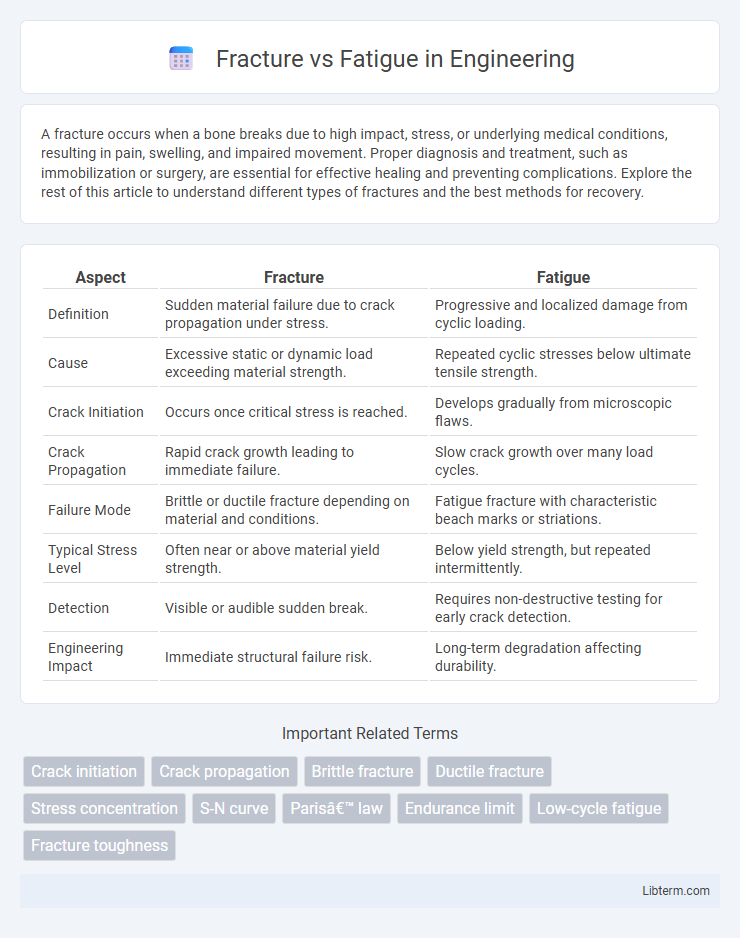

| Aspect | Fracture | Fatigue |

|---|---|---|

| Definition | Sudden material failure due to crack propagation under stress. | Progressive and localized damage from cyclic loading. |

| Cause | Excessive static or dynamic load exceeding material strength. | Repeated cyclic stresses below ultimate tensile strength. |

| Crack Initiation | Occurs once critical stress is reached. | Develops gradually from microscopic flaws. |

| Crack Propagation | Rapid crack growth leading to immediate failure. | Slow crack growth over many load cycles. |

| Failure Mode | Brittle or ductile fracture depending on material and conditions. | Fatigue fracture with characteristic beach marks or striations. |

| Typical Stress Level | Often near or above material yield strength. | Below yield strength, but repeated intermittently. |

| Detection | Visible or audible sudden break. | Requires non-destructive testing for early crack detection. |

| Engineering Impact | Immediate structural failure risk. | Long-term degradation affecting durability. |

Introduction to Fracture and Fatigue

Fracture occurs when a material experiences a sudden and complete separation due to stress exceeding its ultimate strength, often resulting in catastrophic failure. Fatigue involves progressive structural damage from repetitive or cyclic loading well below the material's ultimate tensile strength, leading to crack initiation and growth over time. Understanding the distinction between fracture's immediate breakage and fatigue's gradual deterioration is crucial in materials engineering and structural design.

Defining Fracture: Causes and Characteristics

Fracture refers to the complete or partial breakage of a material due to the application of stress exceeding its strength, often caused by sudden impacts, overloads, or defects within the structure. This failure mode is characterized by the rapid propagation of cracks leading to the material separation, typically exhibiting features such as brittle or ductile fracture surfaces. Common causes include sharp stress concentrators, manufacturing flaws, or extreme loading conditions that surpass the inherent toughness of the material.

Understanding Material Fatigue

Material fatigue occurs due to repeated cyclic loading, leading to the initiation and growth of microscopic cracks that eventually cause fracture. Unlike a sudden fracture caused by a single overload, fatigue damage accumulates over time, significantly influenced by stress amplitude, frequency, and environmental conditions. Understanding material fatigue involves analyzing S-N curves, crack propagation rates, and fatigue limit to predict service life and prevent unexpected failures in engineering components.

Key Differences Between Fracture and Fatigue

Fracture involves the rapid and complete separation of a material under a single load or stress exceeding its strength, resulting in crack propagation until failure. Fatigue, on the other hand, is the progressive and localized structural damage that occurs when a material undergoes repeated cyclic loading, causing cracks to initiate and grow over time even below the material's yield strength. Key differences include fracture being a sudden event often due to a high load, whereas fatigue develops gradually under fluctuating stresses, significantly affecting the lifespan of components such as metals and alloys.

Types of Fractures in Engineering Materials

Types of fractures in engineering materials include brittle, ductile, and fatigue fractures, each differing in crack propagation and energy absorption characteristics. Brittle fractures occur with little plastic deformation and rapid crack growth, often resulting in sudden failure, while ductile fractures involve significant plastic deformation before failure, displaying necking and void coalescence. Fatigue fractures result from cyclic loading that initiates and propagates cracks over time, commonly producing characteristic beach marks or striations on the fracture surface indicative of crack growth stages.

Mechanisms of Fatigue Failure

Fatigue failure occurs through the initiation and propagation of microcracks caused by cyclic stresses below the material's ultimate tensile strength. Repetitive loading leads to localized plastic deformation and crack growth, ultimately resulting in sudden fracture. This mechanism contrasts with fracture, which typically involves crack propagation due to a single overload or static stress event.

Factors Influencing Fracture and Fatigue

Fracture and fatigue are influenced by factors such as material composition, microstructure, and environmental conditions including temperature and corrosion. Stress concentration points, loading frequency, and magnitude significantly affect fatigue life, while fracture toughness, crack propagation rate, and fracture mode determine fracture behavior. Understanding these parameters aids in predicting failure mechanisms and optimizing design for enhanced durability.

Testing Methods for Fracture and Fatigue

Fracture testing typically involves fracture toughness tests such as the ASTM E399 standard, which measures a material's resistance to crack propagation under tensile loading, emphasizing critical stress intensity factors (K_IC). Fatigue testing, governed by standards like ASTM E466, employs cyclic loading to evaluate the number of cycles to failure, generating S-N curves (stress versus number of cycles) that characterize material endurance limits. Both testing methods utilize specialized equipment like servo-hydraulic test machines, with fracture tests focusing on monotonic crack growth and fatigue tests addressing crack initiation and propagation under repeated stress.

Prevention and Control Strategies

Effective prevention and control strategies for fracture and fatigue emphasize material selection, proper design, and regular maintenance. Implementing fatigue-resistant alloys, applying surface treatments such as shot peening, and conducting non-destructive testing like ultrasonic or radiographic inspections significantly reduce failure risks. Stress analysis and load management, combined with real-time monitoring systems, enhance durability and predict potential fracture or fatigue damage in critical structures.

Real-World Applications and Case Studies

Fracture and fatigue are critical failure modes analyzed extensively in engineering fields such as aerospace, automotive, and civil infrastructure, where material integrity under stress determines safety and performance. Real-world applications include aircraft wings subjected to cyclic loading leading to fatigue cracks, contrasted with catastrophic fractures caused by overload or impact in bridge components. Case studies highlight fatigue as a key factor in the 1988 Aloha Airlines incident, where repeated stress cycles caused cracks, whereas fracture analysis prevented failures in pressure vessels by identifying critical crack growth thresholds.

Fracture Infographic

libterm.com

libterm.com