A tight fit ensures secure connections in mechanical assemblies, preventing movement and enhancing stability under stress. Properly designed tight fits minimize gaps that could lead to wear or misalignment, improving the lifespan of components. Discover how mastering tight fit techniques can optimize your projects by reading the full article.

Table of Comparison

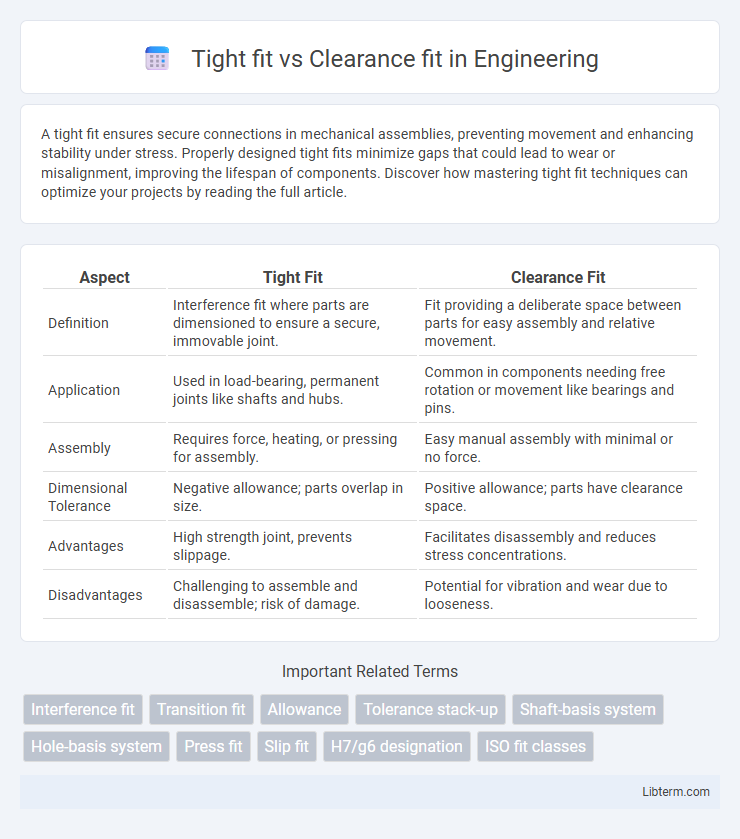

| Aspect | Tight Fit | Clearance Fit |

|---|---|---|

| Definition | Interference fit where parts are dimensioned to ensure a secure, immovable joint. | Fit providing a deliberate space between parts for easy assembly and relative movement. |

| Application | Used in load-bearing, permanent joints like shafts and hubs. | Common in components needing free rotation or movement like bearings and pins. |

| Assembly | Requires force, heating, or pressing for assembly. | Easy manual assembly with minimal or no force. |

| Dimensional Tolerance | Negative allowance; parts overlap in size. | Positive allowance; parts have clearance space. |

| Advantages | High strength joint, prevents slippage. | Facilitates disassembly and reduces stress concentrations. |

| Disadvantages | Challenging to assemble and disassemble; risk of damage. | Potential for vibration and wear due to looseness. |

Introduction to Fits in Engineering

Tight fit and clearance fit are fundamental concepts in engineering that define the allowable tolerance between mating parts. Tight fit, also known as interference fit, ensures components are held securely by friction, often used in permanent assemblies like press fits or shrink fits. Clearance fit provides intentional space between parts for easy assembly and movement, typical in applications requiring rotational or sliding motion such as bearings or shafts.

What is Tight Fit?

Tight fit refers to a type of assembly tolerance where the shaft is slightly larger than the hole, creating an interference that results in a very secure connection without any relative movement. This fit is commonly used in applications requiring high precision and rigidity, such as in machine tool spindles or press-fitted parts. The interference can range from a few micrometers to larger values depending on the tolerance classes defined by ISO or ANSI standards.

What is Clearance Fit?

Clearance fit ensures a space or gap between mating parts, allowing easy assembly and movement without interference or binding. It is characterized by the smallest shaft diameter being less than the largest hole diameter, guaranteeing free play for parts like bolts in holes or shafts in bearings. Common in applications requiring modifications or thermal expansion, clearance fits provide reliable function with minimal wear and easy disassembly.

Key Differences Between Tight Fit and Clearance Fit

Tight fit involves minimal or zero clearance between mating parts, ensuring a secure and often permanent connection ideal for applications requiring precise alignment and high load transfer. Clearance fit provides a deliberate gap between components, allowing easy assembly and movement, suitable for parts that require relative motion or thermal expansion. The key differences lie in the extent of interference or clearance, assembly ease, and functional requirements such as rigidity versus flexibility.

Applications of Tight Fit

Tight fit applications include securing mechanical components such as gears, pulleys, and bearings to shafts, ensuring a firm hold without movement under high torque or load conditions. This type of fit is essential in automotive assemblies, aerospace engineering, and heavy machinery where precise alignment and resistance to vibration are critical. Industries rely on tight fits to prevent slippage and maintain structural integrity in high-stress environments.

Applications of Clearance Fit

Clearance fit is widely applied in assemblies requiring easy mating and disassembly, such as bolts and nuts, bearings on shafts, and pipe fittings. This fit ensures sufficient space between components to permit smooth motion, vibration absorption, and thermal expansion without causing stress or deformation. Common industries leveraging clearance fit include automotive manufacturing, machinery construction, and HVAC systems for reliable and maintainable connections.

Advantages of Tight Fit

Tight fit provides superior load-bearing capacity and precise alignment, making it ideal for applications requiring high strength and minimal movement between mating parts. This fit enhances rigidity and reduces the risk of slippage or vibration in mechanical assemblies. The increased friction in a tight fit also ensures improved sealing and resistance to loosening under dynamic loads.

Advantages of Clearance Fit

Clearance fit offers advantages such as easy assembly and disassembly due to intentional space between mating parts, reducing the risk of damage during installation. It accommodates thermal expansion and manufacturing tolerances, ensuring reliable performance in dynamic or varying environments. This fit type minimizes friction and wear, leading to longer service life and simpler maintenance for mechanical components.

Choosing the Right Fit for Your Project

Choosing the right fit for your project depends on the desired assembly characteristics and operational requirements. Tight fit ensures minimal movement between parts, providing high precision and strength for load-bearing applications, while clearance fit allows controlled space for thermal expansion and easy assembly or disassembly. Evaluate factors such as load conditions, material properties, and environmental influences to determine whether a tight or clearance fit best suits your engineering needs.

Conclusion: Tight Fit vs Clearance Fit

Tight fit provides a secure, immovable joint ideal for applications requiring high precision and load-bearing capabilities, often used in press or shrink fits. Clearance fit allows easy assembly and disassembly with a controlled amount of free play, typically chosen for parts subject to thermal expansion or frequent maintenance. Selecting between tight and clearance fit depends on functional requirements such as load conditions, ease of assembly, and tolerance for movement.

Tight fit Infographic

libterm.com

libterm.com