Magnetic particle testing is a nondestructive inspection method used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. This technique involves magnetizing the component and applying iron particles that gathers at areas with flux leakage, revealing defects like cracks or laps. Explore the rest of the article to understand how magnetic particle testing can improve your quality control processes.

Table of Comparison

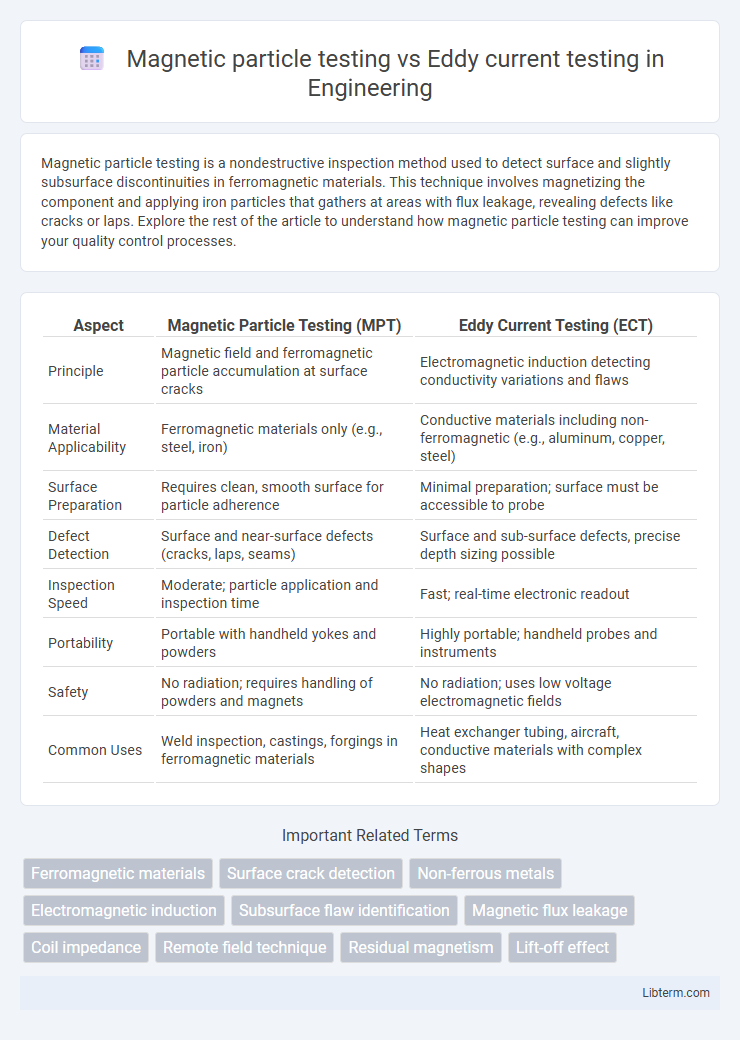

| Aspect | Magnetic Particle Testing (MPT) | Eddy Current Testing (ECT) |

|---|---|---|

| Principle | Magnetic field and ferromagnetic particle accumulation at surface cracks | Electromagnetic induction detecting conductivity variations and flaws |

| Material Applicability | Ferromagnetic materials only (e.g., steel, iron) | Conductive materials including non-ferromagnetic (e.g., aluminum, copper, steel) |

| Surface Preparation | Requires clean, smooth surface for particle adherence | Minimal preparation; surface must be accessible to probe |

| Defect Detection | Surface and near-surface defects (cracks, laps, seams) | Surface and sub-surface defects, precise depth sizing possible |

| Inspection Speed | Moderate; particle application and inspection time | Fast; real-time electronic readout |

| Portability | Portable with handheld yokes and powders | Highly portable; handheld probes and instruments |

| Safety | No radiation; requires handling of powders and magnets | No radiation; uses low voltage electromagnetic fields |

| Common Uses | Weld inspection, castings, forgings in ferromagnetic materials | Heat exchanger tubing, aircraft, conductive materials with complex shapes |

Introduction to Non-Destructive Testing Methods

Magnetic particle testing (MPT) and eddy current testing (ECT) are essential non-destructive testing (NDT) methods used to detect surface and near-surface defects in ferromagnetic materials. MPT relies on the magnetic properties of materials, applying magnetic fields and iron particles to reveal discontinuities, while ECT uses electromagnetic induction to identify flaws based on changes in eddy current flow within conductive materials. Both techniques provide critical inspection capabilities without altering the tested component, ensuring structural integrity and safety in industries like aerospace, manufacturing, and construction.

Understanding Magnetic Particle Testing

Magnetic Particle Testing (MPT) is a non-destructive testing method used to detect surface and near-surface defects in ferromagnetic materials by applying a magnetic field and then scattering iron particles to reveal discontinuities. Unlike Eddy Current Testing, which uses electromagnetic induction to detect flaws primarily in conductive metals, MPT relies on the magnetic permeability of materials to identify cracks, laps, and inclusions. MPT is highly effective for inspecting welds, castings, and forgings, where precise surface defect detection is crucial for safety and quality assurance.

Overview of Eddy Current Testing

Eddy current testing is a non-destructive method that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. It generates eddy currents within the material by applying an alternating magnetic field, which are then analyzed for changes caused by defects or material property variations. This technique is highly sensitive to cracks, corrosion, and thickness measurements, making it ideal for inspecting aircraft components, pipelines, and heat exchanger tubes.

Key Principles of Operation

Magnetic particle testing operates on the principle of magnetizing a ferromagnetic material and detecting surface or near-surface discontinuities through the accumulation of magnetic particles at defect sites, revealing imperfections visually. Eddy current testing involves inducing localized electrical currents in conductive materials using an alternating magnetic field, with flaws identified by changes in the eddy current flow caused by variations in material conductivity or geometry. Both methods rely on detecting anomalies through electromagnetic interactions but target different defect depths and material types for effective non-destructive evaluation.

Applicable Materials and Suitability

Magnetic particle testing is most suitable for ferromagnetic materials like iron, nickel, and cobalt alloys, providing high sensitivity for detecting surface and near-surface discontinuities. Eddy current testing applies to conductive materials, including non-ferromagnetic metals such as aluminum, copper, and stainless steel, making it ideal for surface and sub-surface flaw detection without requiring direct contact. Both methods complement each other, with magnetic particle testing excelling in ferromagnetic applications and eddy current testing offering versatility across a broader range of conductive materials.

Detection Capabilities and Limitations

Magnetic particle testing (MPT) excels in detecting surface and slightly subsurface discontinuities in ferromagnetic materials, offering high sensitivity to cracks and laps but is limited to magnetic materials only. Eddy current testing (ECT) provides versatile defect detection in both conductive and non-ferromagnetic materials, with the ability to identify surface and sub-surface flaws, but its effectiveness decreases with material thickness and requires conductivity differences for accurate results. MPT requires surface preparation and access to the inspection area, while ECT can be used for rapid inspection and sizing of cracks, especially in complex geometries.

Equipment and Setup Requirements

Magnetic particle testing requires a magnetic yoke or coil to magnetize the test surface, along with magnetic particles suspended in a liquid or dry form to reveal surface and near-surface defects. Eddy current testing uses a probe with an electromagnetic coil that induces eddy currents in conductive materials, detecting flaws based on impedance changes without the need for direct contact or magnetic saturation. Setup for magnetic particle testing involves proper surface preparation and ensuring magnetic field orientation, while eddy current testing demands calibration on reference standards and careful probe positioning for accurate flaw detection.

Inspection Speed and Efficiency

Magnetic particle testing offers rapid detection of surface and near-surface defects on ferromagnetic materials, with inspection speeds typically slower due to the need for surface preparation and application of magnetic particles. Eddy current testing provides faster inspection rates, especially on conductive materials, by using electromagnetic induction to quickly identify surface and subsurface flaws without requiring extensive cleaning or demagnetization. Efficiency in eddy current testing is enhanced through automated scanning and real-time signal analysis, making it ideal for high-volume inspections compared to the more labor-intensive magnetic particle method.

Cost Considerations and Accessibility

Magnetic particle testing generally incurs lower costs due to its simpler equipment and ease of use, making it more accessible for basic inspections, especially in field environments. Eddy current testing requires more expensive, sophisticated instruments and trained operators, leading to higher initial investment and operational expenses but offers precise detection of surface and sub-surface flaws. Companies must weigh the immediate affordability and portability of magnetic particle testing against the advanced capabilities and long-term value provided by eddy current testing in specialized applications.

Choosing the Right Method for Your Application

Magnetic particle testing excels in detecting surface and slightly subsurface cracks in ferromagnetic materials, offering high sensitivity for weld inspections and castings. Eddy current testing provides versatile, rapid, and non-contact evaluation of conductive materials, identifying surface and near-surface flaws with precise depth measurement, ideal for complex shapes and thin materials. Selecting the right method depends on material type, defect location, inspection speed, and accessibility requirements, with magnetic particle suited for ferromagnetic components and eddy current preferred for non-ferrous metals and layered structures.

Magnetic particle testing Infographic

libterm.com

libterm.com