Gravity feed systems use the natural force of gravity to move liquids or materials from one point to another without the need for external power sources, enhancing efficiency and reducing energy costs. These systems are commonly utilized in applications such as irrigation, fuel delivery, and fluid transfer where simplicity and reliability are key. Discover how implementing a gravity feed can optimize your process by reading the full article.

Table of Comparison

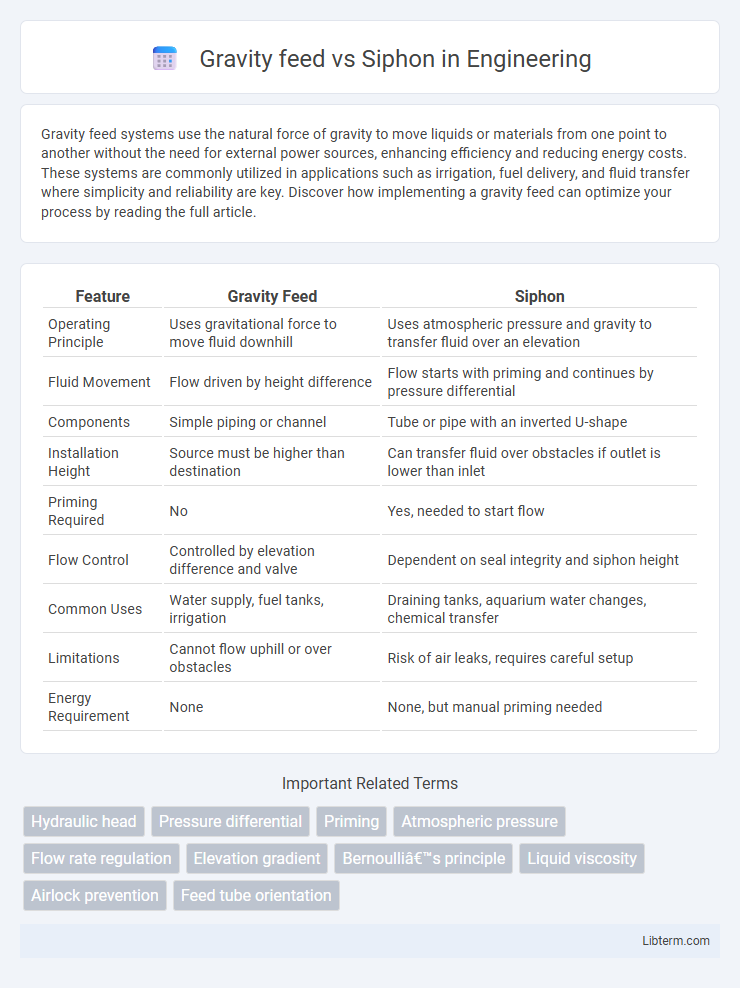

| Feature | Gravity Feed | Siphon |

|---|---|---|

| Operating Principle | Uses gravitational force to move fluid downhill | Uses atmospheric pressure and gravity to transfer fluid over an elevation |

| Fluid Movement | Flow driven by height difference | Flow starts with priming and continues by pressure differential |

| Components | Simple piping or channel | Tube or pipe with an inverted U-shape |

| Installation Height | Source must be higher than destination | Can transfer fluid over obstacles if outlet is lower than inlet |

| Priming Required | No | Yes, needed to start flow |

| Flow Control | Controlled by elevation difference and valve | Dependent on seal integrity and siphon height |

| Common Uses | Water supply, fuel tanks, irrigation | Draining tanks, aquarium water changes, chemical transfer |

| Limitations | Cannot flow uphill or over obstacles | Risk of air leaks, requires careful setup |

| Energy Requirement | None | None, but manual priming needed |

Introduction to Gravity Feed and Siphon Systems

Gravity feed systems rely on the natural force of gravity to move liquids or materials from a higher elevation to a lower point without additional pressure or pumping, making them energy-efficient and simple to maintain. Siphon systems use atmospheric pressure and gravity to transfer fluids between containers, often initiated by creating a vacuum to start the flow over an elevation. Both systems are widely used in irrigation, fluid transfer, and aquariums, with gravity feed offering continuous flow and siphons providing controlled transfer rates.

How Gravity Feed Systems Work

Gravity feed systems operate by utilizing the natural force of gravity to move liquids or materials from a higher elevation to a lower one without the need for pumps or external energy. The system relies on a consistent downward slope, allowing fluid to flow steadily through pipes or channels due to gravitational pull. This method ensures a simple, energy-efficient transfer ideal for water distribution, irrigation, and fuel delivery in various industrial and residential applications.

How Siphon Systems Work

Siphon systems operate by using atmospheric pressure and gravity to move liquid from a higher elevation to a lower elevation through a tube, initiating flow when the liquid is pulled over the siphon's crest. The pressure difference between the entry point at the higher reservoir and the exit below causes the liquid to continue flowing without external pumps. Unlike gravity feed systems that rely solely on gravitational potential, siphons create a continuous flow by balancing fluid pressure and elevation differences within a closed system.

Key Differences Between Gravity Feed and Siphon

Gravity feed relies on the natural force of gravity to move liquids from a higher elevation to a lower one without creating negative pressure, while siphon uses atmospheric pressure and liquid cohesion to transfer fluid over an intermediate higher point before descending. Gravity feed systems are simple, requiring only a height difference, whereas siphons need an initial priming step to start the flow by removing air and creating a continuous stream. Key differences include the reliance on pressure principles, flow initiation methods, and the ability to move liquids over obstacles.

Pros and Cons of Gravity Feed

Gravity feed systems offer a straightforward design that relies on natural gravitational force to move fluids, eliminating the need for pumps and reducing energy consumption. Pros include low maintenance, reliability, and cost-effectiveness in applications like water supply and fuel transfer; however, cons involve limitations in flow control, dependency on elevation differences, and potential issues in consistency when the source level fluctuates. Compared to siphon systems, gravity feed provides simpler installation but lacks the siphon's ability to initiate flow across varying heights without continuous elevation difference.

Pros and Cons of Siphon Systems

Siphon systems offer advantages such as continuous fluid transfer without the need for pumps or external energy, making them efficient and cost-effective for irrigation and drainage applications. However, siphons require a high initial setup with proper elevation differences and can be prone to air locks, which disrupt flow and necessitate regular maintenance. While siphon systems excel in simplicity and low operational costs, their dependability can be compromised by environmental factors and the need for careful design to ensure consistent performance.

Applications: Where Each System Is Used

Gravity feed systems commonly serve residential plumbing, irrigation, and fuel dispensing by utilizing elevation differences to move liquids without mechanical pumps. Siphon systems are preferred in laboratory settings, aquariums, and wastewater management for transferring fluids over obstacles or between containers by exploiting atmospheric pressure and gravity. Each method optimizes fluid movement based on specific spatial and operational constraints, ensuring efficient, energy-free flow in varied applications.

Efficiency and Performance Comparison

Gravity feed systems rely on the natural force of gravity to move liquids from a higher elevation to a lower point, offering consistent flow rates with minimal energy consumption. Siphon systems create fluid movement by atmospheric pressure and cohesion, often requiring precise setup to maintain efficiency and prevent airlocks that reduce performance. Efficiency in gravity feed is generally higher due to fewer mechanical dependencies, while siphons can experience fluctuations in flow, impacting overall performance.

Maintenance and Troubleshooting

Gravity feed systems require minimal maintenance due to their simple design, with occasional checks to prevent blockages and leaks in the fluid lines. Siphon systems demand more frequent inspections to ensure the siphon effect is maintained, including attention to air leaks and priming issues that can disrupt flow. Troubleshooting gravity feed typically involves addressing clogs or fluid flow interruptions, while siphon troubleshooting requires restoring the vacuum seal and clearing any trapped air bubbles to reestablish consistent fluid movement.

Choosing the Right System for Your Needs

Choosing between gravity feed and siphon systems depends on the specific application and efficiency requirements. Gravity feed systems rely on natural gravitational force for fluid movement, making them ideal for simple, low-maintenance setups with minimal mechanical parts and consistent flow rates. Siphon systems, using pressure differentials and atmospheric pressure, offer more controlled fluid transfer in complex configurations, suitable for applications requiring precise liquid displacement or movement across varied elevations.

Gravity feed Infographic

libterm.com

libterm.com