Evaporative cooling is an energy-efficient process that uses the natural evaporation of water to lower air temperature, making it ideal for dry and hot climates. This method reduces reliance on traditional air conditioning, cutting electricity costs and enhancing environmental sustainability. Discover how evaporative cooling can improve Your indoor comfort and save energy by reading the rest of this article.

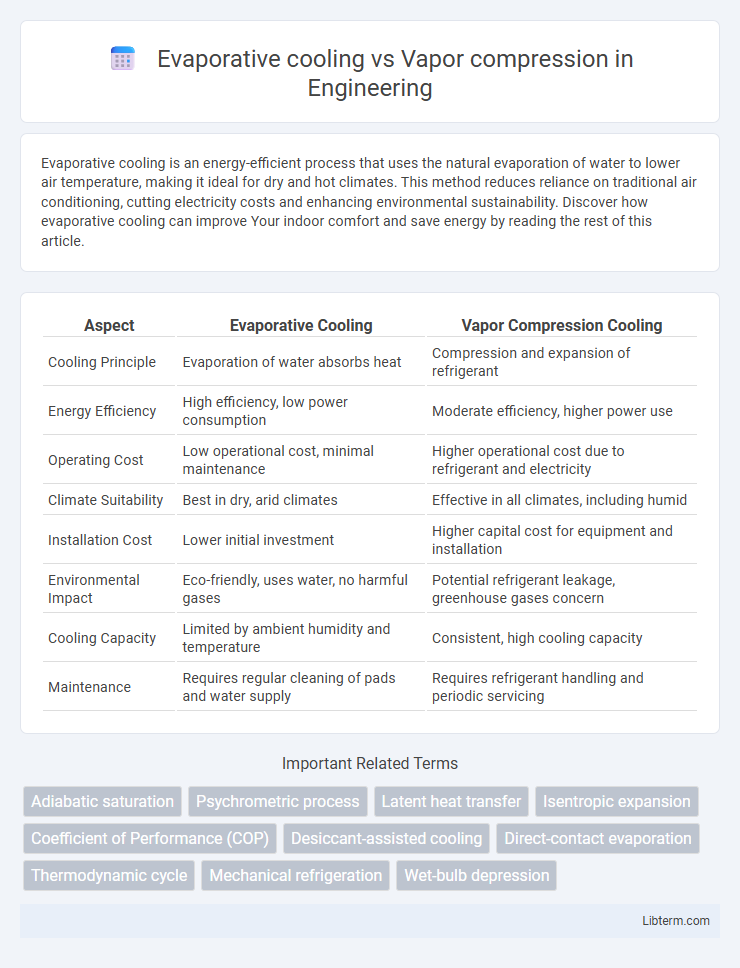

Table of Comparison

| Aspect | Evaporative Cooling | Vapor Compression Cooling |

|---|---|---|

| Cooling Principle | Evaporation of water absorbs heat | Compression and expansion of refrigerant |

| Energy Efficiency | High efficiency, low power consumption | Moderate efficiency, higher power use |

| Operating Cost | Low operational cost, minimal maintenance | Higher operational cost due to refrigerant and electricity |

| Climate Suitability | Best in dry, arid climates | Effective in all climates, including humid |

| Installation Cost | Lower initial investment | Higher capital cost for equipment and installation |

| Environmental Impact | Eco-friendly, uses water, no harmful gases | Potential refrigerant leakage, greenhouse gases concern |

| Cooling Capacity | Limited by ambient humidity and temperature | Consistent, high cooling capacity |

| Maintenance | Requires regular cleaning of pads and water supply | Requires refrigerant handling and periodic servicing |

Introduction to Cooling Technologies

Evaporative cooling utilizes the natural process of water evaporation to absorb heat and lower air temperature, making it an energy-efficient and eco-friendly solution primarily suited for dry climates. Vapor compression cooling relies on a refrigerant cycle involving compression, condensation, expansion, and evaporation to achieve precise temperature control, commonly used in air conditioners and refrigerators worldwide. Both technologies play crucial roles in modern HVAC systems, with vapor compression offering higher efficiency in humid environments while evaporative cooling excels in reducing energy consumption.

How Evaporative Cooling Works

Evaporative cooling operates by passing warm air through water-saturated pads, causing water to evaporate and absorb heat, which significantly lowers the air temperature before it enters a space. This natural process uses less energy compared to vapor compression systems because it relies on the latent heat of vaporization rather than mechanical refrigeration cycles. The efficiency of evaporative coolers is highest in hot, dry climates where low humidity allows maximum evaporation and cooling effect.

How Vapor Compression Cooling Works

Vapor compression cooling operates by circulating a refrigerant through a closed loop involving four key components: the compressor, condenser, expansion valve, and evaporator. The compressor pressurizes the refrigerant vapor, increasing its temperature before it releases heat in the condenser and condenses into a liquid. The liquid refrigerant then passes through the expansion valve, where it experiences a pressure drop and evaporates in the evaporator, absorbing heat from the surrounding air and producing a cooling effect.

Efficiency Comparison: Evaporative vs Vapor Compression

Evaporative cooling systems use the natural process of water evaporation to reduce air temperature, consuming significantly less energy compared to vapor compression systems that rely on mechanical refrigeration cycles. In terms of efficiency, evaporative coolers typically use 75% less electricity, making them more environmentally friendly and cost-effective, especially in dry climates. Vapor compression systems, while more effective in humid or high-temperature environments, demand higher energy input due to compressors and refrigerants, resulting in lower overall energy efficiency.

Environmental Impact and Sustainability

Evaporative cooling systems consume significantly less electricity and use no refrigerants, minimizing greenhouse gas emissions and ozone depletion compared to vapor compression systems that rely on hydrofluorocarbon refrigerants with high global warming potential. The natural cooling mechanism of evaporative coolers reduces energy demand, contributing to lower carbon footprints and enhanced sustainability, especially in arid climates. Vapor compression technology, while efficient in diverse environments, poses environmental concerns due to refrigerant leakage and higher energy consumption, prompting a shift towards eco-friendly refrigerants and alternative cooling methods.

Cost Analysis: Installation and Operating Expenses

Evaporative cooling systems generally have lower installation costs due to simpler components and reduced energy requirements, making them ideal for dry climates. Vapor compression systems incur higher upfront expenses, driven by complex machinery and refrigerants, but typically offer more precise temperature control. Operating expenses are significantly lower for evaporative cooling, with energy consumption up to 75% less than vapor compression units, resulting in substantial savings over time.

Climate Suitability and Geographic Considerations

Evaporative cooling excels in hot, dry climates with low humidity, providing energy-efficient cooling by leveraging water evaporation, while vapor compression systems perform effectively in diverse climates, including humid and high-temperature regions due to their ability to control indoor humidity levels. Geographic considerations such as water availability and ambient air conditions significantly influence the choice; regions with abundant water and arid conditions favor evaporative coolers, whereas vapor compression systems suit urban areas and humid coastal zones. Climate suitability and local environmental factors ultimately determine the optimal cooling technology for energy efficiency and comfort.

Maintenance Requirements and Longevity

Evaporative cooling systems require minimal maintenance, typically involving regular cleaning of pads and water reservoirs to prevent mold and scale buildup, contributing to longer operational lifespan in dry climates. Vapor compression systems demand frequent inspections and servicing of compressors, refrigerant levels, and electrical components to maintain efficiency and avoid system failures. Proper upkeep of vapor compression units significantly influences their longevity, while evaporative coolers benefit from simpler maintenance routines that reduce overall wear and tear.

Applications: Residential, Commercial, and Industrial

Evaporative cooling systems excel in residential and commercial applications where dry climates prevail, offering energy-efficient and cost-effective cooling solutions ideal for open or semi-open spaces such as homes, offices, and warehouses. Vapor compression systems dominate in residential, commercial, and industrial settings requiring precise temperature control and humidity regulation, including HVAC systems, refrigerated storage, and manufacturing processes. Industrial applications often favor vapor compression for its versatility and ability to handle high cooling loads, while evaporative cooling remains preferred in industries like agriculture and textile for its sustainable and low operational cost benefits.

Choosing the Right Cooling System

Evaporative cooling systems offer energy-efficient, eco-friendly solutions ideal for dry, hot climates by using water evaporation to lower air temperature. Vapor compression systems provide precise temperature control and dehumidification, making them suitable for humid environments and commercial applications. Selecting the right cooling system depends on climate, energy costs, humidity levels, and specific cooling requirements.

Evaporative cooling Infographic

libterm.com

libterm.com