Radial-flow refers to a type of fluid movement where the flow direction is perpendicular to the axis of rotation, commonly seen in pumps, compressors, and turbines. This design enhances efficiency by promoting uniform pressure distribution and minimizing energy loss in various industrial applications. Discover how understanding radial-flow systems can optimize your equipment's performance by exploring the detailed insights in the rest of this article.

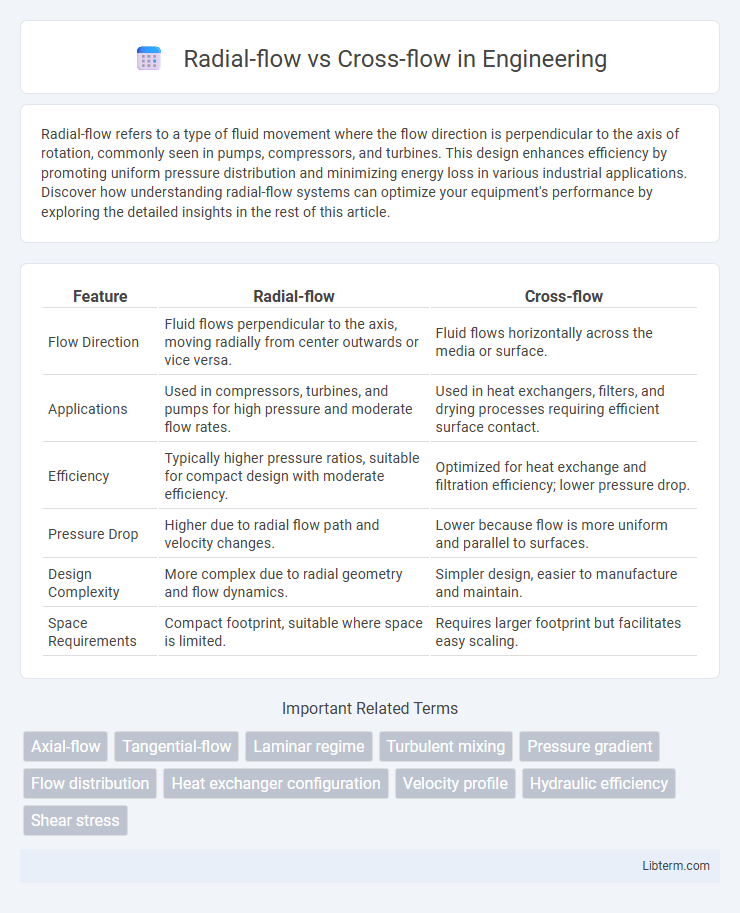

Table of Comparison

| Feature | Radial-flow | Cross-flow |

|---|---|---|

| Flow Direction | Fluid flows perpendicular to the axis, moving radially from center outwards or vice versa. | Fluid flows horizontally across the media or surface. |

| Applications | Used in compressors, turbines, and pumps for high pressure and moderate flow rates. | Used in heat exchangers, filters, and drying processes requiring efficient surface contact. |

| Efficiency | Typically higher pressure ratios, suitable for compact design with moderate efficiency. | Optimized for heat exchange and filtration efficiency; lower pressure drop. |

| Pressure Drop | Higher due to radial flow path and velocity changes. | Lower because flow is more uniform and parallel to surfaces. |

| Design Complexity | More complex due to radial geometry and flow dynamics. | Simpler design, easier to manufacture and maintain. |

| Space Requirements | Compact footprint, suitable where space is limited. | Requires larger footprint but facilitates easy scaling. |

Introduction to Radial-flow and Cross-flow

Radial-flow and cross-flow refer to two primary configurations of flow patterns in filtration and heat exchange systems, influencing efficiency and performance. Radial-flow involves fluid moving perpendicularly outward or inward through a medium, maximizing contact area and allowing uniform distribution across the filter or heat exchanger. Cross-flow, in contrast, directs fluid parallel to the filter surface, promoting continuous filtration with reduced clogging by carrying away particles, widely applied in membrane filtration technologies.

Basic Principles of Radial-flow

Radial-flow filters operate by directing fluid from the center of the filter outward through a porous medium, maximizing the effective filtration area and ensuring uniform flow distribution. This basic principle enhances particle capture efficiency by promoting radial movement, which contrasts with cross-flow filters where fluid flows parallel to the membrane surface, minimizing clogging. Radial-flow systems are commonly used in applications requiring high throughput and consistent filtration, such as water treatment and biochemical processes.

Basic Principles of Cross-flow

Cross-flow filtration operates by directing feed solution tangentially across the surface of the membrane, allowing permeate to pass through while retaining larger particles and solutes on the membrane surface. This tangential flow minimizes membrane fouling by continuously sweeping away accumulated solids, enhancing filtration efficiency and membrane lifespan. Key parameters influencing cross-flow filtration include flow velocity, transmembrane pressure, and membrane pore size, which collectively determine separation performance and throughput.

Key Differences Between Radial-flow and Cross-flow

Radial-flow filters direct fluid perpendicularly from the center outward through the filter media, maximizing filtration efficiency in applications requiring high dirt-holding capacity. Cross-flow filters channel fluid tangentially across the membrane surface, promoting shear forces that reduce fouling and extend membrane life in continuous separation processes. The primary differences involve flow direction, fouling tendencies, and operational application, with radial-flow suited for batch filtration and cross-flow optimal for continuous filtration systems.

Advantages of Radial-flow Systems

Radial-flow filtration systems offer increased efficiency by allowing fluid to move perpendicular to the filter media, minimizing clogging and extending filter life. These systems provide higher flow rates and improved particle retention compared to cross-flow designs, enhancing overall filtration performance. Radial-flow mechanisms also reduce energy consumption and maintenance costs due to their streamlined flow paths and effective debris separation.

Advantages of Cross-flow Systems

Cross-flow filtration systems offer higher flux rates and improved fouling control by allowing feedwater to flow tangentially across the membrane surface, which reduces particle accumulation. These systems facilitate easier cleaning and maintenance, extending membrane lifespan and operational efficiency. Cross-flow designs also provide better separation performance in treating liquids with high suspended solids or complex feed compositions.

Common Applications of Radial-flow

Radial-flow filters are commonly used in water treatment, air filtration, and chemical processing industries where high dirt-holding capacity and uniform flow distribution are essential. These filters efficiently handle large volumes of liquid or gas while maintaining consistent pressure drop, making them ideal for municipal water purification and industrial wastewater treatment. Their design minimizes clogging and allows for easier maintenance compared to cross-flow filters, especially in applications with high particulate loads.

Common Applications of Cross-flow

Cross-flow membranes are widely used in water treatment and wastewater purification due to their efficiency in separating contaminants while maintaining high flow rates. Common applications include microfiltration and ultrafiltration in industrial processes like dairy processing, pulp and paper production, and pharmaceutical manufacturing. Their design minimizes fouling and supports continuous operation, making them ideal for applications requiring consistent filtration performance.

Performance Comparison: Efficiency and Output

Radial-flow compressors typically exhibit higher pressure ratios and are more efficient at handling large volumes of air with lower flow rates, making them ideal for high-pressure applications. Cross-flow compressors provide more uniform airflow distribution and better thermal performance, which can enhance output stability in variable load conditions. Performance comparison reveals radial-flow designs excel in efficiency and output at steady-state operations, while cross-flow units offer improved adaptability and consistent performance under fluctuating demands.

Choosing the Right Flow System for Your Needs

Radial-flow and cross-flow systems each offer distinct advantages based on application requirements, with radial-flow excelling in high-capacity filtration due to its perpendicular fluid direction and compact design, while cross-flow systems provide superior fouling resistance by allowing continuous sweeping of the membrane surface. Selecting the appropriate flow system depends on factors such as feed water quality, desired recovery rates, and maintenance frequency, where radial-flow suits suspended solids removal in larger volumes and cross-flow is preferred for challenging feeds with high fouling potential. Evaluating these parameters ensures optimal membrane performance, longevity, and cost-efficiency tailored to specific industrial or municipal water treatment needs.

Radial-flow Infographic

libterm.com

libterm.com