Transformation hardening enhances the wear resistance and strength of steel by causing a phase transformation in the microstructure when rapidly cooled. This process results in a hard martensitic structure, significantly improving the material's durability under mechanical stress. Discover how transformation hardening can strengthen your components and explore its applications in the full article.

Table of Comparison

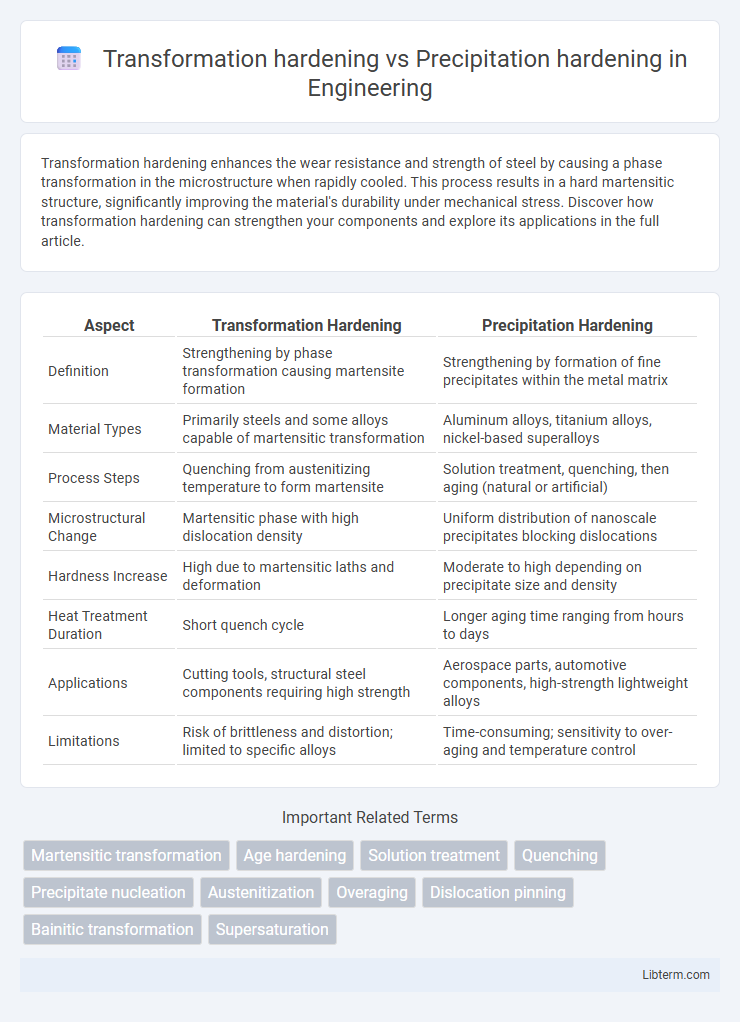

| Aspect | Transformation Hardening | Precipitation Hardening |

|---|---|---|

| Definition | Strengthening by phase transformation causing martensite formation | Strengthening by formation of fine precipitates within the metal matrix |

| Material Types | Primarily steels and some alloys capable of martensitic transformation | Aluminum alloys, titanium alloys, nickel-based superalloys |

| Process Steps | Quenching from austenitizing temperature to form martensite | Solution treatment, quenching, then aging (natural or artificial) |

| Microstructural Change | Martensitic phase with high dislocation density | Uniform distribution of nanoscale precipitates blocking dislocations |

| Hardness Increase | High due to martensitic laths and deformation | Moderate to high depending on precipitate size and density |

| Heat Treatment Duration | Short quench cycle | Longer aging time ranging from hours to days |

| Applications | Cutting tools, structural steel components requiring high strength | Aerospace parts, automotive components, high-strength lightweight alloys |

| Limitations | Risk of brittleness and distortion; limited to specific alloys | Time-consuming; sensitivity to over-aging and temperature control |

Introduction to Hardening Mechanisms

Transformation hardening enhances steel strength by rapidly cooling austenite to create martensite, increasing hardness through phase transformation. Precipitation hardening strengthens alloys by forming fine, dispersed particles that impede dislocation movement during aging. Both mechanisms improve mechanical properties through distinct microstructural modifications tailored to specific industrial applications.

What is Transformation Hardening?

Transformation hardening is a heat treatment process that increases the hardness of metals by altering their microstructure through phase transformation, commonly involving the rapid cooling of steel to form martensite. This method enhances mechanical properties by converting austenite into a harder phase, typically martensite or bainite, resulting in improved wear resistance and strength. Unlike precipitation hardening, which relies on the formation of fine particles within the metal matrix, transformation hardening depends on diffusionless phase changes to achieve hardness.

What is Precipitation Hardening?

Precipitation hardening, also known as age hardening, is a heat treatment process that enhances the strength and hardness of alloys by forming fine particles, or precipitates, within the metal matrix. These precipitates hinder dislocation movement, resulting in improved mechanical properties. This method contrasts with transformation hardening, which relies on phase changes like martensite formation to increase hardness.

Key Differences Between Transformation and Precipitation Hardening

Transformation hardening involves altering the microstructure of metals through phase changes, typically by quenching and tempering steel to form martensite, enhancing hardness and strength. Precipitation hardening relies on the formation of fine, dispersed particles within an alloy matrix during aging, which obstruct dislocation movement and improve mechanical properties. Key differences include the mechanisms of strength increase--phase transformation for transformation hardening versus particle precipitation for precipitation hardening--and their typical application materials, with transformation hardening common in steels and precipitation hardening used mainly in aluminum, nickel, and titanium alloys.

Microstructural Changes in Transformation Hardening

Transformation hardening involves rapid cooling that induces a martensitic transformation, resulting in a supersaturated, distorted body-centered tetragonal structure that increases hardness through lattice strain. The microstructural changes include the formation of needle-like martensite plates from austenite, characterized by high dislocation density and internal stresses. This contrasts with precipitation hardening, where fine secondary phase particles precipitate within the matrix, obstructing dislocation motion and enhancing strength without altering the base crystal structure.

Microstructural Evolution in Precipitation Hardening

Precipitation hardening enhances mechanical properties by forming finely dispersed intermetallic precipitates within the metal matrix, creating obstacles to dislocation movement and increasing strength. During microstructural evolution, the alloy undergoes solution treatment, quenching, and aging, which leads to the nucleation, growth, and coarsening of strengthening precipitates such as GP zones, metastable phases, and stable precipitates. In contrast, transformation hardening relies on phase changes like martensitic transformation, which alters the microstructure primarily through diffusionless shear mechanisms rather than precipitate formation.

Applications of Transformation Hardening

Transformation hardening, commonly applied in automotive and aerospace industries, enhances surface durability and wear resistance of components like gears and shafts through controlled phase changes in steel microstructure. This technique is favored for manufacturing heavy-duty parts requiring high strength and toughness without compromising core ductility. Its applications extend to tooling and structural components where enhanced fatigue strength and impact resistance are critical.

Applications of Precipitation Hardening

Precipitation hardening is extensively used in aerospace, automotive, and defense industries due to its ability to significantly enhance the strength and fatigue resistance of aluminum, titanium, and nickel-based alloys. This process optimizes the microstructure by forming fine, dispersed precipitates that impede dislocation movement, making it ideal for components like aircraft structural parts, turbine blades, and high-performance engine components. Transformation hardening, while effective for surface wear resistance in steels, lacks the versatile application range of precipitation hardening in lightweight, high-strength alloys critical to advanced engineering fields.

Comparative Advantages and Limitations

Transformation hardening offers rapid surface strengthening by inducing martensitic phase changes, enhancing wear resistance but often at the expense of increased brittleness and potential distortion. Precipitation hardening improves overall material strength and toughness through controlled formation of fine precipitates within the alloy matrix, providing superior balance between hardness and ductility yet requiring precise thermal treatments. While transformation hardening is efficient for localized hardness improvements, precipitation hardening delivers more uniform and stable mechanical properties across the bulk material.

Choosing the Right Hardening Technique for Materials

Transformation hardening is ideal for steels requiring increased surface hardness and wear resistance through rapid cooling that induces martensitic transformation. Precipitation hardening suits aluminum and nickel alloys, enhancing strength by forming fine precipitates during controlled aging processes. Selecting the right technique depends on the base material composition, desired mechanical properties, and application-specific performance requirements.

Transformation hardening Infographic

libterm.com

libterm.com