A rolling pair is a mechanical component consisting of two cylindrical rollers used to reduce friction between moving parts in machinery. These pairs enhance efficiency by enabling smoother motion and minimizing wear on surfaces. Explore the rest of the article to understand how rolling pairs improve your equipment's performance and durability.

Table of Comparison

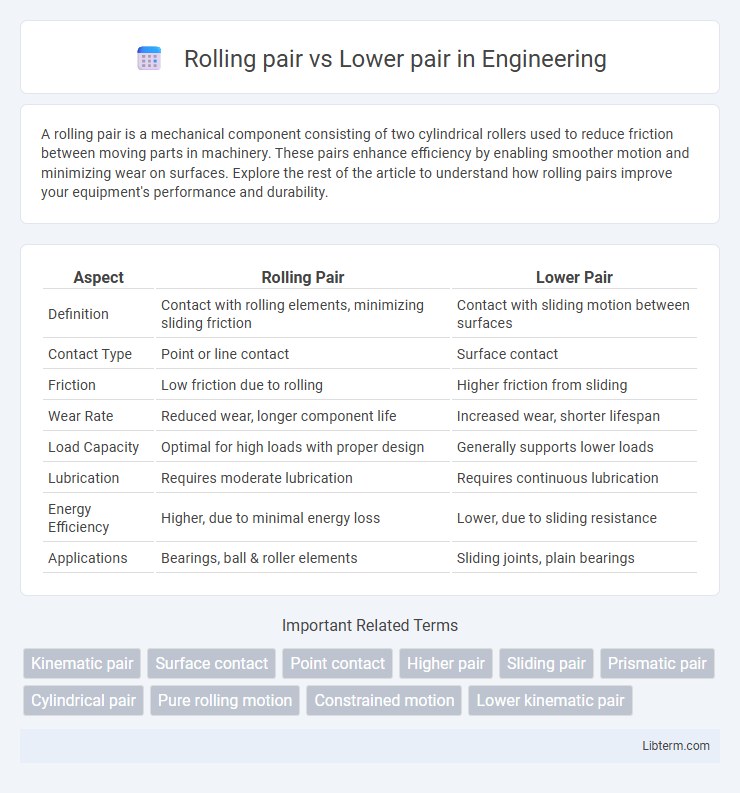

| Aspect | Rolling Pair | Lower Pair |

|---|---|---|

| Definition | Contact with rolling elements, minimizing sliding friction | Contact with sliding motion between surfaces |

| Contact Type | Point or line contact | Surface contact |

| Friction | Low friction due to rolling | Higher friction from sliding |

| Wear Rate | Reduced wear, longer component life | Increased wear, shorter lifespan |

| Load Capacity | Optimal for high loads with proper design | Generally supports lower loads |

| Lubrication | Requires moderate lubrication | Requires continuous lubrication |

| Energy Efficiency | Higher, due to minimal energy loss | Lower, due to sliding resistance |

| Applications | Bearings, ball & roller elements | Sliding joints, plain bearings |

Introduction to Rolling Pairs and Lower Pairs

Rolling pairs are mechanical components where rolling elements, such as balls or rollers, facilitate relative motion with minimal friction, commonly found in bearings and cam mechanisms. Lower pairs involve surface contact between two elements allowing relative motion constrained by geometric forms, including revolute and prismatic pairs in kinematic chains. Understanding the distinction between rolling pairs and lower pairs is essential in designing efficient mechanical linkages and reducing wear and energy losses.

Definitions: What are Rolling Pairs and Lower Pairs?

Rolling pairs are kinematic pairs where the relative motion between two contacting elements involves pure rolling without slipping, such as in ball bearings and cam-follower mechanisms. Lower pairs refer to joints where the contact between elements is surface-based, allowing relative motion with constraints like sliding, rolling, or turning, examples include revolute (hinge) and prismatic (slider) pairs. Rolling pairs emphasize point or line contact with rolling motion, whereas lower pairs cover a broader range of surface contacts facilitating various constrained relative movements.

Structural Differences Between Rolling and Lower Pairs

Rolling pairs feature elements that roll over each other, minimizing sliding friction through the use of rolling elements such as balls or rollers, whereas lower pairs rely on surface contact and relative sliding between components, like in hinge or slider joints. Structural differences include the presence of rolling elements in rolling pairs, which allow for smooth rotational or linear movement, while lower pairs involve direct contact and constraints that guide motion with sliding or turning action. These variations impact the mechanisms' design, durability, and friction characteristics, making rolling pairs preferable for applications requiring reduced wear and higher efficiency.

Types and Examples of Rolling Pairs

Rolling pairs in mechanical engineering include types such as ball bearings, roller bearings, and needle bearings, which utilize rolling elements to reduce friction between moving parts. Common examples of rolling pair components are ball and socket joints, cylindrical roller bearings, and tapered roller bearings, each designed for specific load and motion applications. These pairs excel in minimizing friction and wear compared to lower pairs like revolute and prismatic joints, which rely on sliding contact surfaces.

Types and Examples of Lower Pairs

Lower pairs in kinematics are characterized by surface or area contact between elements, allowing rotational or sliding motion, examples include revolute joints (pin joints) and prismatic joints (slider joints). Other types of lower pairs are cylindrical pairs, where one element has cylindrical surface motion relative to another, and cam and follower pairs that enable rotational to reciprocating motion conversion. Rolling pairs differ by having line or point contact, exemplified by gears and rolling bearings, emphasizing minimal friction during motion.

Motion Characteristics: Rolling vs Lower Pair

Rolling pairs exhibit rolling motion between cylindrical or spherical surfaces, minimizing friction and enabling smooth, continuous movement ideal for bearings and cam mechanisms. Lower pairs involve surface contact with higher friction due to sliding motion, typically found in mechanisms like gears and sliders where precise controlled movement is essential. The distinct motion characteristics dictate their applications, with rolling pairs favoring low-resistance motion and lower pairs ensuring rigidity and constraint in mechanical systems.

Applications in Mechanisms and Machines

Rolling pairs, consisting of two elements in rolling contact, offer reduced friction and wear, making them ideal for applications such as bearings, gears, and cam mechanisms where smooth and efficient motion is critical. Lower pairs, characterized by surface contact with higher friction, are commonly used in joints and linkages, such as hinged or sliding connections found in robotic arms and mechanical linkages requiring precise control and load transfer. The choice between rolling pairs and lower pairs in machines greatly influences efficiency, durability, and motion accuracy in diverse mechanical systems.

Advantages and Limitations of Rolling Pairs

Rolling pairs in mechanical systems provide reduced friction and wear compared to lower pairs, enhancing efficiency and durability in applications like bearings and gear contacts. Their design promotes smoother motion with lower energy loss, but they typically require precise manufacturing and are less tolerant to misalignment or shock loads. Although rolling pairs excel in high-speed scenarios, they may have limitations in load capacity and complexity compared to simpler lower pair mechanisms such as sliding or turning pairs.

Advantages and Limitations of Lower Pairs

Lower pairs provide precise and rigid motion control due to their surface contact, which enhances load-carrying capacity and stability in mechanical systems. However, their limitations include increased friction and wear from continuous surface contact, necessitating regular lubrication and maintenance. Rolling pairs, by contrast, reduce friction significantly but may offer less stability under heavy loads compared to lower pairs.

Key Differences: Rolling Pair vs Lower Pair

Rolling pairs involve contact between curved surfaces allowing rolling motion with minimal friction, commonly seen in ball bearings and gear teeth. Lower pairs feature surface contact between two elements enabling constrained relative motion, such as revolute or prismatic pairs in mechanisms. Key differences lie in rolling pairs having point or line contact promoting smooth rotation, while lower pairs maintain surface contact facilitating guided motion with sliding or rolling components.

Rolling pair Infographic

libterm.com

libterm.com