The Geneva drive is a mechanism that converts continuous rotational motion into intermittent rotary motion, commonly used in watches and film projectors for precise indexing. This device features a driving wheel with a pin that engages slots on the Geneva wheel, causing it to advance in fixed increments. Discover how the Geneva drive's unique design enhances accuracy and efficiency in various mechanical applications by reading the rest of the article.

Table of Comparison

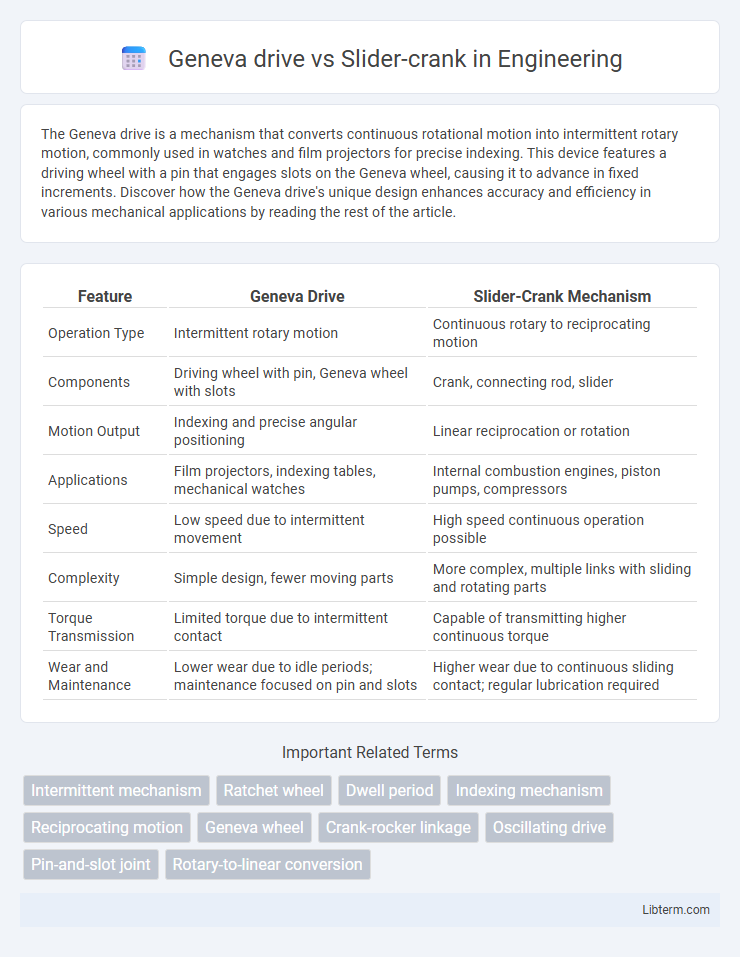

| Feature | Geneva Drive | Slider-Crank Mechanism |

|---|---|---|

| Operation Type | Intermittent rotary motion | Continuous rotary to reciprocating motion |

| Components | Driving wheel with pin, Geneva wheel with slots | Crank, connecting rod, slider |

| Motion Output | Indexing and precise angular positioning | Linear reciprocation or rotation |

| Applications | Film projectors, indexing tables, mechanical watches | Internal combustion engines, piston pumps, compressors |

| Speed | Low speed due to intermittent movement | High speed continuous operation possible |

| Complexity | Simple design, fewer moving parts | More complex, multiple links with sliding and rotating parts |

| Torque Transmission | Limited torque due to intermittent contact | Capable of transmitting higher continuous torque |

| Wear and Maintenance | Lower wear due to idle periods; maintenance focused on pin and slots | Higher wear due to continuous sliding contact; regular lubrication required |

Introduction to Geneva Drive and Slider-Crank Mechanisms

The Geneva drive is a mechanical indexing mechanism that converts continuous rotation into intermittent rotary motion, widely used in film projectors and indexing tables for precise step-by-step movement. The slider-crank mechanism transforms rotary motion into reciprocating linear motion or vice versa, commonly found in engines and pumps for converting piston movement into rotary output. Both mechanisms are fundamental in mechanical design, offering distinct motion conversion solutions tailored to automation and power transmission applications.

Fundamental Working Principles

The Geneva drive converts continuous rotational motion into intermittent rotary motion through a pin engaging with slots, ensuring precise indexing steps. The slider-crank mechanism transforms rotary motion into linear motion via a crank linked to a sliding component, enabling smooth reciprocating activity. Both mechanisms rely on rigid links and pivot points but serve distinct motion conversion purposes in mechanical systems.

Key Structural Differences

The Geneva drive features a rotating wheel with slots that engage a driving pin to produce intermittent motion, emphasizing precise indexing and dwell periods, while the slider-crank mechanism converts rotary motion into linear motion through a crank, connecting rod, and slider assembly. Geneva drives typically have a simpler, compact structure designed for discrete steps, whereas slider-cranks involve multiple interconnected components with continuous motion. The Geneva mechanism minimizes wear due to intermittent engagement, whereas slider-crank designs are optimized for smooth transmission of power in applications like engines and pumps.

Motion Output Characteristics

Geneva drives produce intermittent rotary motion with precise indexing, ideal for applications requiring exact angular positioning, while slider-crank mechanisms convert rotary motion into smooth, continuous reciprocating motion, suited for engines and pumps. Geneva drives feature distinct dwell periods where the output remains stationary, enhancing timing accuracy, whereas slider-cranks exhibit sinusoidal velocity profiles resulting in variable speed throughout their cycle. The Geneva mechanism's motion output is highly discrete, contrasting with the slider-crank's continuous, oscillatory output tailored for uniform force transmission.

Applications in Modern Machinery

Geneva drives are widely used in indexing mechanisms for precise, intermittent motion in film projectors, automatic machinery, and packaging equipment, ensuring accurate positioning. Slider-crank mechanisms convert rotary motion to linear motion efficiently, proving essential in internal combustion engines, compressors, and piston pumps. Both mechanisms optimize motion control, but Geneva drives excel in stepwise rotation, while slider-cranks dominate applications requiring continuous linear displacement.

Efficiency and Performance Comparison

The Geneva drive offers high positional accuracy and is ideal for intermittent motion applications, delivering efficient mechanical indexing with minimal slip. The slider-crank mechanism provides smooth continuous rotational-to-reciprocal motion conversion, excelling in applications requiring consistent torque and speed control. While the Geneva drive excels in precision and energy efficiency during starts and stops, the slider-crank achieves superior performance in continuous motion and power transmission scenarios.

Durability and Maintenance Considerations

Geneva drives exhibit high durability due to their simple, robust intermittent motion mechanism, requiring minimal maintenance and offering long service life under moderate load conditions. Slider-crank mechanisms experience greater wear from continuous sliding friction, necessitating regular lubrication and more frequent maintenance to prevent component degradation. For applications demanding long intervals between maintenance and consistent reliability, the Geneva drive is typically more advantageous than a slider-crank linkage.

Customization and Design Flexibility

Geneva drives offer limited customization due to their fixed index positions and mechanical simplicity, making them ideal for precise intermittent motion but less adaptable to varied motion profiles. Slider-crank mechanisms provide greater design flexibility with adjustable stroke lengths, variable speed capabilities, and easy integration into complex machinery, allowing engineers to tailor motion parameters extensively. Customization in slider-crank designs supports a wide range of applications from engine pistons to automated machinery, whereas Geneva drives are primarily suited for applications requiring consistent, repeatable indexing.

Cost Implications for Implementation

Geneva drives typically incur lower manufacturing costs due to fewer moving parts and simpler machining processes, making them cost-effective for intermittent motion applications. Slider-crank mechanisms involve more complex components and precise assembly, leading to higher initial investment and maintenance expenses. Factoring in longevity and operational requirements, Geneva drives provide a budget-friendly solution for repetitive indexing, whereas slider-crank systems justify their cost in continuous or variable-speed motion scenarios.

Choosing the Right Mechanism for Your Needs

Selecting between a Geneva drive and a slider-crank mechanism depends on application requirements such as precision, speed, and motion type. Geneva drives excel in indexing applications requiring accurate intermittent rotation, while slider-crank mechanisms are ideal for converting rotary motion into smooth reciprocating motion. Consider factors like load capacity, complexity, and maintenance when choosing the right mechanism for your engineering project.

Geneva drive Infographic

libterm.com

libterm.com