Field balancing ensures rotating equipment operates smoothly by minimizing vibration and preventing premature wear. Proper balancing extends the lifespan of machinery, improves performance, and reduces maintenance costs. Discover how field balancing can enhance your equipment's reliability by exploring the full article.

Table of Comparison

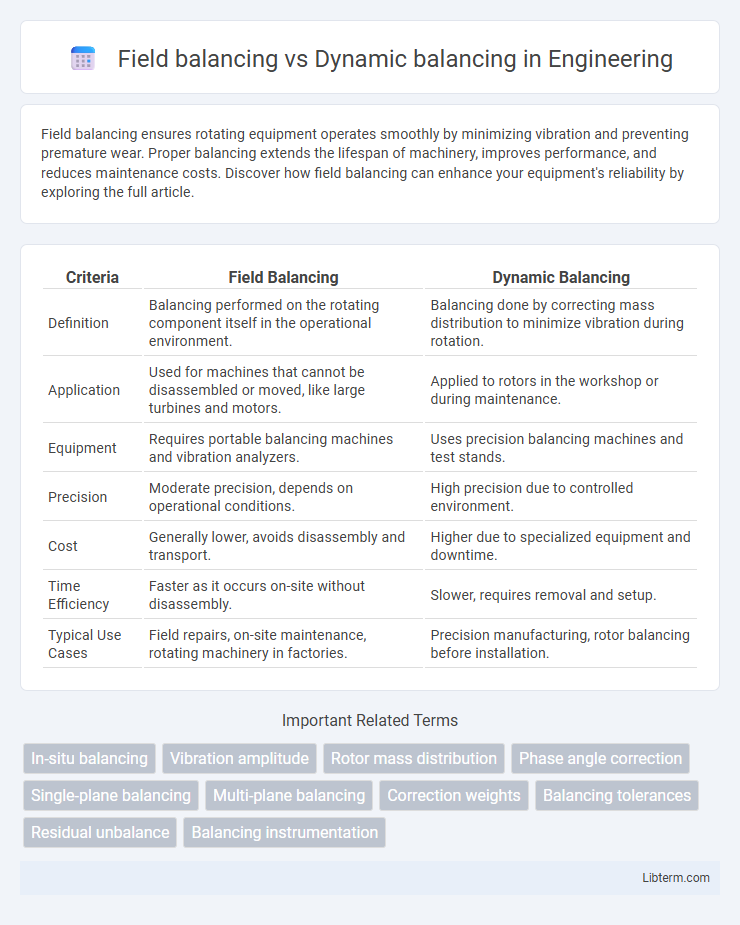

| Criteria | Field Balancing | Dynamic Balancing |

|---|---|---|

| Definition | Balancing performed on the rotating component itself in the operational environment. | Balancing done by correcting mass distribution to minimize vibration during rotation. |

| Application | Used for machines that cannot be disassembled or moved, like large turbines and motors. | Applied to rotors in the workshop or during maintenance. |

| Equipment | Requires portable balancing machines and vibration analyzers. | Uses precision balancing machines and test stands. |

| Precision | Moderate precision, depends on operational conditions. | High precision due to controlled environment. |

| Cost | Generally lower, avoids disassembly and transport. | Higher due to specialized equipment and downtime. |

| Time Efficiency | Faster as it occurs on-site without disassembly. | Slower, requires removal and setup. |

| Typical Use Cases | Field repairs, on-site maintenance, rotating machinery in factories. | Precision manufacturing, rotor balancing before installation. |

Introduction to Field Balancing and Dynamic Balancing

Field balancing involves correcting imbalance in rotating machinery by adjusting masses directly on the rotor during operation, targeting specific planes to reduce vibration and increase efficiency. Dynamic balancing measures and compensates for both static and couple imbalances by analyzing vibrations in multiple planes, often requiring specialized equipment to ensure smooth, high-speed rotation. Both methods optimize rotor performance but differ in complexity and application scope, with field balancing suited for quick adjustments and dynamic balancing providing thorough precision.

Key Differences Between Field Balancing vs Dynamic Balancing

Field balancing targets correcting imbalance in a specific rotor location by adding weight at a single plane, while dynamic balancing addresses imbalance across multiple planes to reduce vibration during rotation. Field balancing is typically performed on-site without removing the rotor, whereas dynamic balancing requires specialized equipment to measure and correct the rotor's dynamic forces in a controlled environment. The key difference lies in the scope and precision, with dynamic balancing offering a comprehensive correction for complex imbalance compared to the localized approach of field balancing.

What Is Field Balancing?

Field balancing is a precise technique used to correct rotor imbalance by adjusting the mass distribution within the rotating field or magnetic poles of an electric motor, ensuring smooth operation and reducing vibration. Unlike dynamic balancing, which addresses imbalance by adding weights to the rotor's external surfaces, field balancing modifies the electromagnetic field directly to achieve stability. This method is particularly effective in high-speed motors where mechanical additions could disrupt performance or increase wear.

What Is Dynamic Balancing?

Dynamic balancing involves correcting the imbalance in rotating machinery by measuring and adjusting the mass distribution across multiple planes to reduce vibrations during operation. Unlike field balancing, which is performed on the rotor outside the system, dynamic balancing occurs while the rotor spins at operating speed, enabling precise identification of imbalances in real-time. This method enhances machine performance and longevity by minimizing operational wear and noise caused by uneven mass distribution.

Applications of Field Balancing in Industry

Field balancing is essential in rotating machinery like turbines, compressors, and motors to reduce vibration and extend equipment lifespan by correcting mass distribution directly on the rotating element. Its applications in industries such as aerospace, automotive, and manufacturing improve operational efficiency and prevent mechanical failures caused by unbalanced rotors. Dynamic balancing, while also important, targets imbalances during operation, making field balancing the preferred method for ensuring precise rotor stability in industrial settings.

Typical Uses for Dynamic Balancing

Dynamic balancing is typically used in rotating machinery such as turbines, motors, and automotive components where uneven mass distribution causes vibrations during operation. It corrects imbalances that occur in multiple planes, enhancing the lifespan and performance of high-speed equipment. This method is essential for precision instruments and industrial compressors to ensure smooth, efficient, and reliable function under dynamic conditions.

Pros and Cons: Field Balancing vs Dynamic Balancing

Field balancing offers precise correction of imbalance at specific rotational planes, making it effective for simple, single-plane components, but it may not address complex multi-plane issues. Dynamic balancing corrects imbalance across multiple planes simultaneously, providing better performance for rotors with complex geometries, yet it requires more sophisticated equipment and time. While field balancing is cost-effective and quicker, dynamic balancing delivers superior accuracy and reliability for high-speed rotating machinery.

Factors to Consider When Choosing a Balancing Method

Field balancing is ideal for rotors with mass distribution issues detected during operation, requiring correction without disassembly, while dynamic balancing suits newly manufactured or extensively repaired rotors needing precise correction on dual planes. Consider rotor speed, accessibility, cost, and accuracy demands when choosing; field balancing offers quicker fixes with moderate precision, whereas dynamic balancing demands specialized equipment but ensures high accuracy. The complexity of the rotor and maintenance schedules also influence the decision, with dynamic balancing favored for high-speed machinery to minimize vibration and extend equipment life.

Tools and Equipment for Field and Dynamic Balancing

Field balancing utilizes portable tools such as handheld vibration analyzers, laser alignment systems, and balancing machines designed for on-site adjustments without disassembly. Dynamic balancing requires specialized equipment including high-speed balancing machines, spool-type rotors, and precision sensors integrated into testing rigs for accurate rotational analysis. Both methods rely on advanced instrumentation, but field balancing emphasizes mobility and real-time data capture, whereas dynamic balancing focuses on controlled laboratory conditions and detailed rotor dynamics.

Conclusion: Selecting the Right Balancing Technique

Field balancing is ideal for correcting imbalance in rotating parts by adding or removing material on a specific plane, offering precise control for simple, low-speed applications. Dynamic balancing addresses imbalance across multiple planes and is essential for high-speed, complex rotors to reduce vibration and extend equipment life. Choosing the right technique depends on rotor complexity, operating speed, and required precision, with dynamic balancing being preferred for advanced machinery demanding enhanced performance and longevity.

Field balancing Infographic

libterm.com

libterm.com