Reciprocating compressors use a piston driven by a crankshaft to compress gases within a cylinder, offering high efficiency and precise control over pressure levels. These compressors are widely used in applications requiring high-pressure outputs, such as refrigeration, gas pipelines, and chemical industries. Explore the full article to understand how your operations can benefit from reciprocating compressors and their maintenance tips.

Table of Comparison

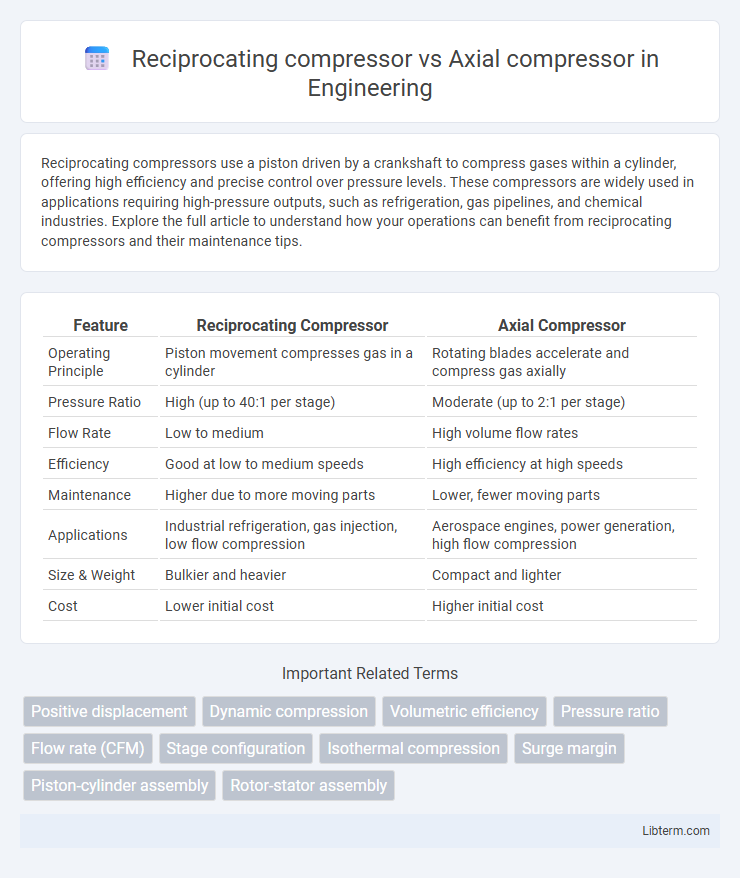

| Feature | Reciprocating Compressor | Axial Compressor |

|---|---|---|

| Operating Principle | Piston movement compresses gas in a cylinder | Rotating blades accelerate and compress gas axially |

| Pressure Ratio | High (up to 40:1 per stage) | Moderate (up to 2:1 per stage) |

| Flow Rate | Low to medium | High volume flow rates |

| Efficiency | Good at low to medium speeds | High efficiency at high speeds |

| Maintenance | Higher due to more moving parts | Lower, fewer moving parts |

| Applications | Industrial refrigeration, gas injection, low flow compression | Aerospace engines, power generation, high flow compression |

| Size & Weight | Bulkier and heavier | Compact and lighter |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Compressor Technologies

Reciprocating compressors use pistons driven by a crankshaft to compress gas in discrete chambers, providing high pressure output with excellent efficiency for low flow rates. Axial compressors employ rotating airfoils to continuously accelerate and compress gas along the axis of rotation, ideal for high flow rate applications such as jet engines and gas turbines. Understanding these fundamental differences helps optimize compressor selection based on performance requirements, operating conditions, and mechanical complexity.

Overview of Reciprocating Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress gas within cylinders, achieving high pressures ideal for applications requiring precise pressure control and intermittent operation. These compressors deliver superior efficiency for low-flow, high-pressure tasks such as in natural gas processing and refrigeration cycles. Their robust design allows handling of diverse gases and operating conditions with reliable performance and ease of maintenance.

Overview of Axial Compressors

Axial compressors are rotary machines that increase air pressure by accelerating airflow through multiple stages of rotating and stationary blades, making them ideal for high-flow, high-speed applications such as jet engines and large gas turbines. They offer continuous airflow with high efficiency and relatively low weight compared to reciprocating compressors, which rely on pistons to compress air in discrete strokes. Axial compressors excel in maintaining stable pressure ratios at high velocities, supporting large-scale industrial processes and aerospace propulsion systems.

Working Principles: Reciprocating vs Axial Compressors

Reciprocating compressors operate by using a piston within a cylinder to compress gas through a linear motion, creating high pressure in small volumes suitable for precise applications. Axial compressors achieve compression by progressively compressing gas through multiple rows of rotating and stationary blades, enabling high flow rates and continuous operation ideal for jet engines and large industrial processes. The fundamental working difference lies in reciprocating compressors' positive displacement mechanism versus axial compressors' dynamic compression through aerodynamic force.

Efficiency Comparison: Reciprocating and Axial Compressors

Reciprocating compressors typically achieve higher efficiency at low flow rates due to their positive displacement design, which minimizes energy loss during compression cycles. Axial compressors excel in high flow rate applications, offering better aerodynamic efficiency and continuous compression with lower pressure fluctuations. Efficiency comparison indicates reciprocating compressors are more suitable for variable loads, while axial compressors provide superior performance in large-scale, high-speed environments.

Applications and Industries: Where Each Compressor Excels

Reciprocating compressors excel in applications requiring high pressure and low flow rates, making them ideal for industries such as oil and gas, chemical processing, and refrigeration where precision and durability under variable loads are critical. Axial compressors, preferred in aerospace, power generation, and large-scale HVAC systems, deliver high flow rates with continuous, stable airflow, making them suitable for jet engines, gas turbines, and industrial ventilation. Both compressors find unique industrial niches based on flow requirements and pressure demands, optimizing efficiency and operational reliability.

Maintenance and Reliability Factors

Reciprocating compressors require frequent maintenance due to their complex moving parts like pistons, rings, and valves that experience wear and tear, leading to higher downtime compared to axial compressors. Axial compressors, with fewer moving parts and continuous flow operation, generally offer higher reliability and longer maintenance intervals, making them ideal for large-scale industrial applications. However, axial compressors demand precise alignment and blade inspections to maintain efficiency and prevent catastrophic failures, whereas reciprocating compressors benefit from routine lubrication and component replacement to sustain performance.

Space, Size, and Installation Requirements

Reciprocating compressors require more space due to their larger size and multiple moving parts, making installation more complex in confined areas. Axial compressors have a compact, streamlined design ideal for installations where space is limited, commonly used in aerospace and large-scale industrial applications. The simpler foundation and alignment needs of axial compressors contrast with the robust structural support and vibration mitigation required for reciprocating compressor installations.

Cost Analysis: Initial Investment and Operational Costs

Reciprocating compressors generally require lower initial investment costs due to simpler design and manufacturing processes, making them suitable for low to medium flow rates. Axial compressors, while having higher initial capital expenses due to complex engineering and precision components, offer greater energy efficiency and reduced operational costs in high-flow, continuous-duty applications. Maintenance costs for reciprocating compressors tend to be higher because of numerous moving parts and frequent wear, whereas axial compressors benefit from lower maintenance frequency and longer service intervals, influencing total lifecycle costs.

Choosing the Right Compressor: Key Considerations

Choosing between a reciprocating compressor and an axial compressor depends primarily on the required pressure ratio, flow rate, and application specificity. Reciprocating compressors excel in high-pressure, low-flow scenarios, offering precise control and robustness for industrial gas compression. Axial compressors are optimal for high-flow, low to moderate pressure applications, commonly used in jet engines and large-scale ventilation systems due to their efficiency and compact design.

Reciprocating compressor Infographic

libterm.com

libterm.com