The notch on devices like smartphones and laptops houses essential components such as cameras and sensors while maximizing screen space for an immersive viewing experience. Its design balances function and aesthetics, enabling manufacturers to deliver sleek devices without compromising on technology. Explore the full article to understand how the notch impacts your device's usability and design trends.

Table of Comparison

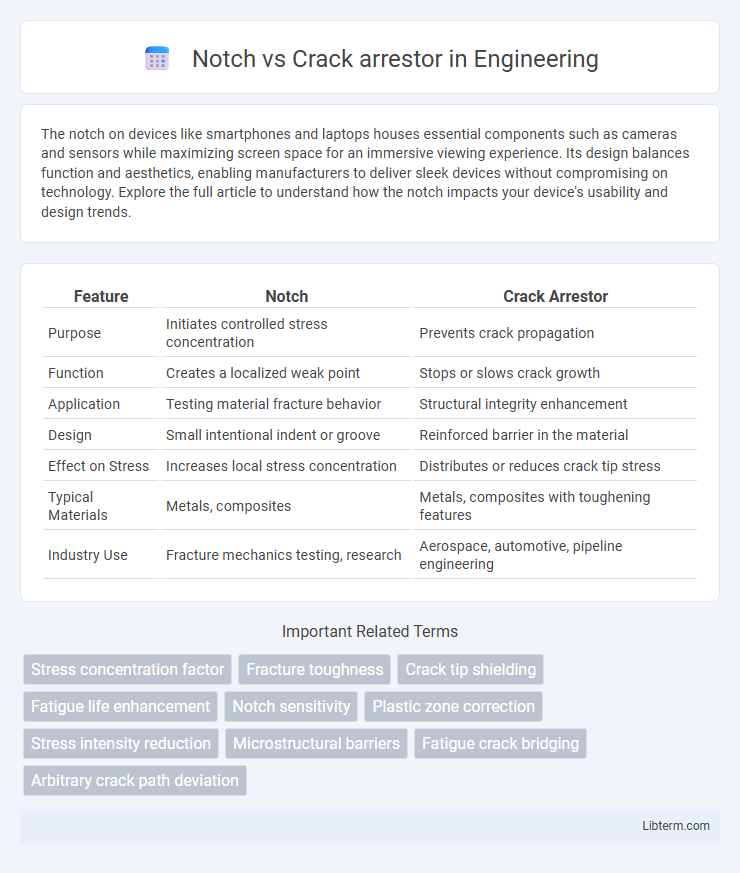

| Feature | Notch | Crack Arrestor |

|---|---|---|

| Purpose | Initiates controlled stress concentration | Prevents crack propagation |

| Function | Creates a localized weak point | Stops or slows crack growth |

| Application | Testing material fracture behavior | Structural integrity enhancement |

| Design | Small intentional indent or groove | Reinforced barrier in the material |

| Effect on Stress | Increases local stress concentration | Distributes or reduces crack tip stress |

| Typical Materials | Metals, composites | Metals, composites with toughening features |

| Industry Use | Fracture mechanics testing, research | Aerospace, automotive, pipeline engineering |

Introduction to Notches and Crack Arrestors

Notches are intentional geometric discontinuities introduced in structures to influence stress distribution and control crack propagation. Crack arrestors are specialized components or design features installed to halt or slow the progression of cracks, enhancing structural integrity. Both notches and crack arrestors play critical roles in fracture mechanics by managing stress concentrations and preventing catastrophic failure in engineering materials.

Understanding Material Failure: Notches vs. Cracks

Notches act as stress concentrators in materials, significantly increasing localized stress and often serving as initiation points for crack propagation. Crack arrestors are designed to interrupt crack growth by redistributing stress and preventing further material failure. Understanding the differences between notch-induced stress concentration and actual crack propagation is essential for predicting structural integrity and optimizing failure prevention strategies.

The Role of Notches in Structural Integrity

Notches serve as intentional stress concentrators that can influence crack initiation and propagation within structural materials, directly impacting their integrity. By carefully designing notch geometry and placement, engineers can control stress distribution and delay crack growth, enhancing durability and safety. Crack arrestors work synergistically with notches by halting or slowing crack extension, but the primary role of notches lies in managing localized stress fields to maintain overall structural performance.

Crack Arrestors: Definition and Function

Crack arrestors are specialized devices designed to prevent the propagation of cracks in structural components by redirecting stress concentrations away from critical areas. They function by increasing the local toughness and dissipating energy around the crack tip, thereby enhancing the integrity and durability of materials under mechanical stress. Commonly used in pipelines, pressure vessels, and aerospace structures, crack arrestors play a crucial role in maintaining safety and preventing catastrophic failure.

Comparative Analysis: Notch vs. Crack Arrestor

Notches concentrate stress at specific points, increasing the likelihood of crack initiation, while crack arrestors are designed to redistribute stress and halt crack propagation. Notch effectiveness depends on geometry and material properties, often reducing fatigue life, whereas crack arrestors improve structural integrity by interrupting crack growth through altered stress fields. In applications requiring enhanced durability, crack arrestors provide a superior solution by mitigating crack extension instead of merely creating controlled stress risers like notches.

Applications in Engineering and Manufacturing

Notch arrestors are primarily utilized in structural engineering to prevent the propagation of cracks in welded joints and metal components, enhancing the durability of critical infrastructure like bridges and aircraft frames. Crack arrestors find extensive application in manufacturing processes, especially in pipeline systems and pressure vessels, where they inhibit crack growth to maintain safety and operational integrity. Both devices are essential for extending the lifespan of engineering materials by controlling stress concentration points and improving failure resistance under cyclic loading conditions.

Impact on Fatigue Life and Fracture Mechanics

Notch arrestors reduce stress concentration by blunting crack tips, significantly improving fatigue life by slowing crack initiation and propagation under cyclic loading. Crack arrestors are designed to halt crack growth by introducing localized toughness or barriers, effectively preventing fracture propagation and enhancing damage tolerance. Both techniques optimize fracture mechanics by managing crack tip stresses, but notch arrestors primarily extend fatigue life while crack arrestors focus on stopping crack growth to prevent catastrophic failure.

Design Considerations for Enhanced Durability

Notch arrestors require precise geometric modifications to disrupt crack propagation by concentrating stress around specific points, optimizing material toughness for durability. Crack arrestors incorporate features such as increased thickness, rounded transitions, or stiffening elements to slow or halt crack growth, enhancing structural integrity over time. Design considerations emphasize material selection, stress distribution, and fatigue resistance to maximize the lifespan and performance of both notch and crack arrestor systems.

Case Studies: Real-World Use of Notches and Crack Arrestors

Case studies reveal that notches and crack arrestors play critical roles in mitigating structural failure in aerospace and civil engineering applications. For example, in aircraft wing design, crack arrestors have effectively limited crack propagation, enhancing fatigue life and safety margins, while strategic notch placement in pipeline systems has controlled stress concentration, preventing unexpected fractures. Analysis of real-world failures underscores that proper integration of these elements, tailored to material properties and load conditions, significantly improves durability and reduces maintenance costs.

Future Trends in Damage Prevention Technologies

Future trends in damage prevention technologies for notch and crack arrestors emphasize the integration of sensor-based monitoring systems and advanced materials like shape memory alloys for real-time detection and adaptive response. Innovations in machine learning algorithms enable predictive maintenance by analyzing stress patterns and crack propagation tendencies to preempt structural failures. These advancements collectively enhance the efficiency, reliability, and lifespan of critical infrastructure components in aerospace, civil engineering, and manufacturing sectors.

Notch Infographic

libterm.com

libterm.com