The piezoelectric effect occurs when certain materials generate an electric charge in response to applied mechanical stress, enabling direct energy conversion between mechanical and electrical forms. This phenomenon is widely utilized in sensors, actuators, and energy harvesting devices to enhance performance and sensitivity. Explore the rest of the article to understand how the piezoelectric effect can benefit your applications and technologies.

Table of Comparison

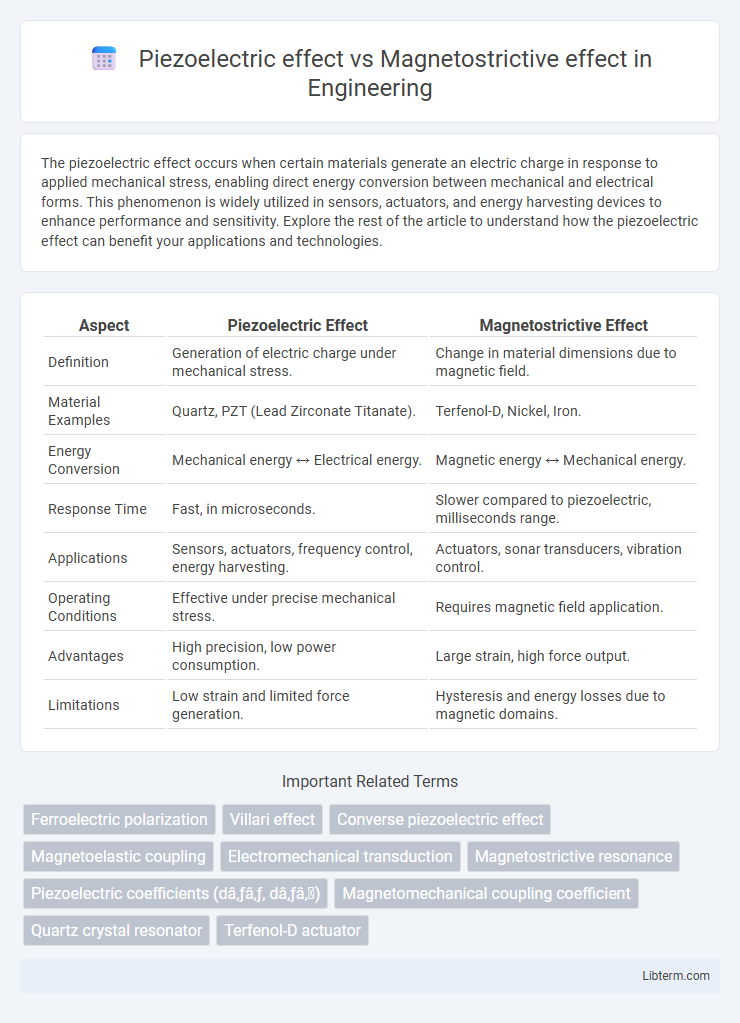

| Aspect | Piezoelectric Effect | Magnetostrictive Effect |

|---|---|---|

| Definition | Generation of electric charge under mechanical stress. | Change in material dimensions due to magnetic field. |

| Material Examples | Quartz, PZT (Lead Zirconate Titanate). | Terfenol-D, Nickel, Iron. |

| Energy Conversion | Mechanical energy ↔ Electrical energy. | Magnetic energy ↔ Mechanical energy. |

| Response Time | Fast, in microseconds. | Slower compared to piezoelectric, milliseconds range. |

| Applications | Sensors, actuators, frequency control, energy harvesting. | Actuators, sonar transducers, vibration control. |

| Operating Conditions | Effective under precise mechanical stress. | Requires magnetic field application. |

| Advantages | High precision, low power consumption. | Large strain, high force output. |

| Limitations | Low strain and limited force generation. | Hysteresis and energy losses due to magnetic domains. |

Introduction to Solid-State Sensing Phenomena

Piezoelectric effect involves the generation of electric charge in certain solid materials such as quartz or ceramics when mechanical stress is applied, making it essential for sensors that convert physical pressure into electrical signals. Magnetostrictive effect occurs when magnetic materials like iron or nickel change shape or dimensions in response to a magnetic field, enabling sensors that detect changes in magnetic environments through mechanical deformation. Both effects are fundamental solid-state sensing phenomena exploited in diverse applications including vibration measurement, ultrasonic transducers, and position sensing technologies.

Understanding the Piezoelectric Effect

The piezoelectric effect occurs when certain materials generate an electric charge in response to applied mechanical stress, making it fundamental in sensors, actuators, and energy harvesting devices. This phenomenon relies on the material's crystal structure lacking a center of symmetry, allowing direct conversion between mechanical and electrical energy. Understanding the piezoelectric effect involves analyzing the material's polarization changes under mechanical deformation, which differs from the magnetostrictive effect that involves magnetic field-induced strain in ferromagnetic materials.

Fundamentals of Magnetostrictive Effect

The magnetostrictive effect in ferromagnetic materials involves a change in shape or dimensions when subjected to a magnetic field due to realignment of magnetic domains. Unlike the piezoelectric effect, which generates an electric charge in response to mechanical stress, magnetostriction directly couples magnetic and mechanical energies, enabling precise control of movement in actuators and sensors. Advanced applications exploit materials like Terfenol-D for high magnetostrictive strain and rapid response in energy harvesting and ultrasonic transducers.

Material Classes: Piezoelectric vs Magnetostrictive

Piezoelectric materials, typically ceramics such as lead zirconate titanate (PZT) and quartz crystals, generate electric charge in response to mechanical stress, enabling precise sensor and actuator applications. Magnetostrictive materials, including alloys like Terfenol-D and galfenol, change shape or dimensions when exposed to magnetic fields, making them ideal for high-force actuators and energy harvesting devices. The fundamental distinction lies in piezoelectrics converting mechanical energy into electrical energy, while magnetostrictives couple magnetic energy with mechanical deformation.

Working Principles: How They Generate Signal

The piezoelectric effect generates signals by converting mechanical stress into an electrical charge through the deformation of crystalline structures, such as quartz or ceramics. In contrast, the magnetostrictive effect produces signals by altering the magnetic properties of ferromagnetic materials when subjected to mechanical strain, causing a change in magnetic flux that can be detected electrically. Both effects rely on material-specific physical changes induced by mechanical forces, but piezoelectric sensors output voltage directly, while magnetostrictive sensors require magnetic field sensing components to convert strain into electrical signals.

Key Differences in Physical Mechanisms

The piezoelectric effect involves the generation of an electric charge in certain crystals and ceramics when subjected to mechanical stress, relying on the displacement of ions within non-centrosymmetric crystal lattices. In contrast, the magnetostrictive effect arises from the change in shape or dimensions of ferromagnetic materials when exposed to a magnetic field, driven by the reorientation of magnetic domains. These differing physical mechanisms highlight how piezoelectric materials convert mechanical energy directly into electrical energy, while magnetostrictive materials convert magnetic energy into mechanical strain.

Typical Applications of Piezoelectric Materials

Piezoelectric materials are widely used in precision actuators, sensors, and ultrasonic transducers due to their ability to convert mechanical stress into electrical charge and vice versa. Typical applications include medical ultrasound imaging, piezoelectric buzzers, and vibration sensors, where high sensitivity and fast response are essential. Compared to magnetostrictive materials, piezoelectrics offer higher frequency operation and better miniaturization capabilities in electronic devices.

Industrial Uses of Magnetostrictive Materials

Magnetostrictive materials are extensively used in industrial applications such as precision actuators, vibration sensors, and ultrasonic transducers due to their ability to convert magnetic energy into mechanical strain efficiently. These materials enable high-frequency operation and robust performance in harsh environments, making them ideal for nondestructive testing and energy harvesting systems. Compared to the piezoelectric effect, magnetostrictive materials offer greater durability and adaptability in applications requiring strong magnetic fields and variable load conditions.

Advantages and Limitations: A Comparative Overview

The piezoelectric effect offers high sensitivity and precision in applications such as sensors and actuators, with advantages including fast response times and compact size, but it is limited by its dependency on brittle ceramic materials and lower energy output. In contrast, the magnetostrictive effect provides robustness and higher energy conversion efficiency ideal for heavy-duty actuators and power generation, yet suffers from slower response and hysteresis affecting accuracy. Both effects are crucial in electromechanical systems, with the piezoelectric effect favored for high-frequency applications and magnetostriction preferred in environments requiring durability and high power.

Future Directions in Smart Material Technologies

Piezoelectric effect research is advancing towards energy harvesting applications and self-powered sensors in wearable and implantable devices, leveraging materials like lead-free ceramics and flexible polymers. Magnetostrictive effect developments focus on high-precision actuation and tunable microwave components, utilizing novel alloys such as Galfenol and Terfenol-D for enhanced magneto-mechanical coupling. Integration of these smart materials with IoT and AI-driven systems promises breakthroughs in adaptive, multifunctional devices for aerospace, robotics, and healthcare sectors.

Piezoelectric effect Infographic

libterm.com

libterm.com