Riveted joints provide strong, permanent fastening by joining metal components with rivets that create reliable shear and tensile strength. These joints are commonly used in construction, automotive, and aerospace industries due to their durability and resistance to vibration. Discover how understanding riveted joints can enhance your projects by reading the rest of the article.

Table of Comparison

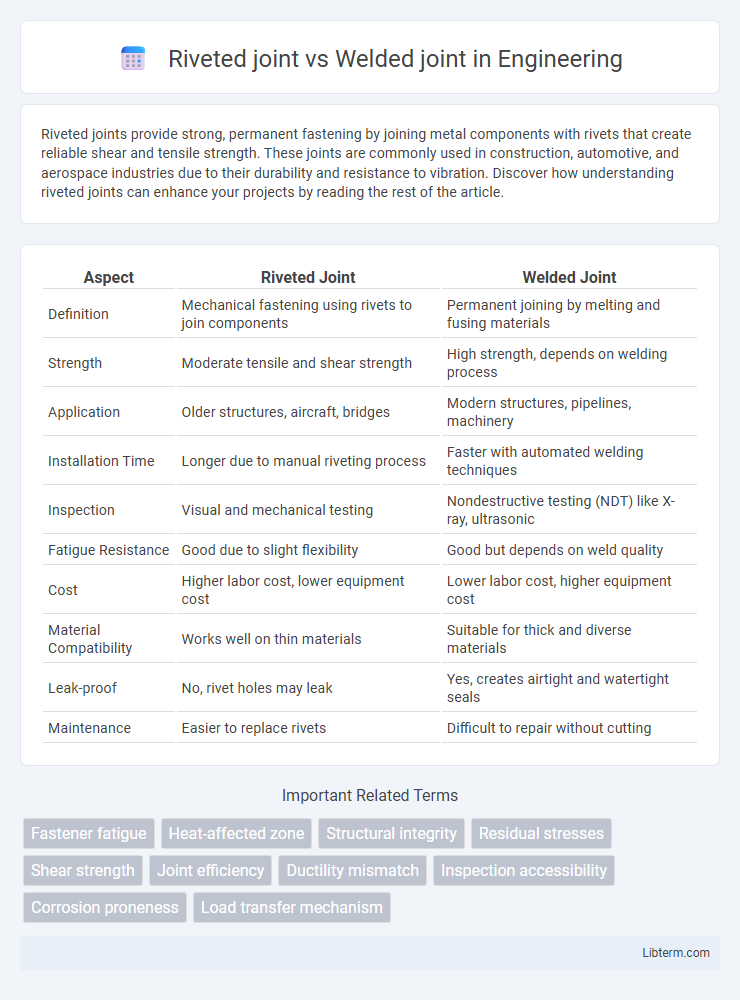

| Aspect | Riveted Joint | Welded Joint |

|---|---|---|

| Definition | Mechanical fastening using rivets to join components | Permanent joining by melting and fusing materials |

| Strength | Moderate tensile and shear strength | High strength, depends on welding process |

| Application | Older structures, aircraft, bridges | Modern structures, pipelines, machinery |

| Installation Time | Longer due to manual riveting process | Faster with automated welding techniques |

| Inspection | Visual and mechanical testing | Nondestructive testing (NDT) like X-ray, ultrasonic |

| Fatigue Resistance | Good due to slight flexibility | Good but depends on weld quality |

| Cost | Higher labor cost, lower equipment cost | Lower labor cost, higher equipment cost |

| Material Compatibility | Works well on thin materials | Suitable for thick and diverse materials |

| Leak-proof | No, rivet holes may leak | Yes, creates airtight and watertight seals |

| Maintenance | Easier to replace rivets | Difficult to repair without cutting |

Introduction to Riveted and Welded Joints

Riveted joints use metal pins called rivets to hold two or more components together by deformation of the rivet tail, creating a strong mechanical bond primarily used in metal structures like bridges and ships. Welded joints join materials by melting and fusing their edges, producing a continuous and rigid connection widely applied in construction, automotive, and manufacturing industries. The choice between riveted and welded joints depends on factors such as load requirements, material thickness, and environmental conditions.

Definition and Principles of Riveted Joints

Riveted joints are mechanical fasteners used to join two or more metal plates by inserting a metal pin, known as a rivet, through aligned holes and deforming the tail to create a permanent union. This joint relies on the principle of friction and interference fit, where the clamping force generated by the deformed rivet prevents separation under load and transmits shear forces between connected members. Unlike welded joints, which fuse metal parts through high heat, riveted joints maintain structural integrity through mechanical deformation without altering the base metal's microstructure.

Definition and Principles of Welded Joints

Welded joints are formed by melting base metals and adding a filler material, creating a continuous and strong bond upon solidification. The principle of welding relies on heat generation through methods like arc, gas, or resistance to fuse materials at the joint interface. Compared to riveted joints, which use mechanical fasteners and rely on shear and bearing strength, welded joints provide a seamless connection with superior load-bearing capacity and resistance to fatigue.

Materials and Tools Used in Both Joints

Riveted joints typically use steel or aluminum rivets along with tools such as rivet guns and hammers to create mechanical fastening in structures like bridges and aircraft. Welded joints require compatible metals like carbon steel, stainless steel, or aluminum alloys and specialized equipment including welding machines, electrodes, and protective gear to fuse materials at high temperatures. Material selection for riveting emphasizes ductility and shear strength, while welding demands metals with suitable thermal conductivity and melting points for effective fusion.

Strength and Load-Bearing Capacity Comparison

Riveted joints provide reliable shear strength and are effective for load-bearing in dynamic or vibrating structures, distributing stress uniformly across multiple rivets. Welded joints offer superior tensile strength and create a continuous metal bond, enhancing load-bearing capacity under static and high-stress conditions. The choice between riveted and welded joints depends on specific load types, with welding generally preferred for high-strength, rigid connections and riveting favored for applications requiring flexibility and fatigue resistance.

Durability and Maintenance Requirements

Riveted joints provide high durability in dynamic or vibrating structures due to their ability to absorb stresses without cracking, making them suitable for maintenance-heavy environments where easy inspection and replacement are crucial. Welded joints offer superior strength and uniform load distribution, but they require specialized inspection techniques and can be prone to cracks if not properly maintained, leading to higher maintenance complexity. Both joint types demand distinct maintenance approaches: riveted joints focus on bolt tightening and replacement, while welded joints require thorough non-destructive testing to ensure structural integrity over time.

Cost Analysis: Riveted vs. Welded Joints

Riveted joints typically incur higher labor costs due to the manual or semi-automated riveting process, whereas welded joints benefit from faster application and automation, reducing overall labor expenses. Material costs for riveted joints include additional components like rivets and overlapping plates, increasing the total expenditure compared to welded joints, which require only base metal and welding consumables. Maintenance and inspection costs tend to be higher for riveted joints due to potential loosening and corrosion at rivet holes, while welded joints often offer greater durability and lower long-term maintenance costs.

Applications in Various Industries

Riveted joints are widely used in aerospace and construction industries due to their ability to withstand dynamic loads and vibrations without compromising structural integrity. Welded joints dominate in automotive manufacturing and shipbuilding, providing strong, permanent bonds that ensure high strength and corrosion resistance. Both joining methods are selected based on material compatibility, load requirements, and environmental conditions specific to each industry's standards and safety regulations.

Advantages and Disadvantages of Each Joint

Riveted joints offer advantages such as easy inspection, vibration resistance, and suitability for joining dissimilar metals, but they tend to have lower strength and require more labor-intensive assembly compared to welded joints. Welded joints provide higher strength, better sealing against fluids, and a more streamlined appearance, though they may suffer from residual stresses, require skilled labor, and are less effective on thin or heat-sensitive materials. Selection depends on application demands, material properties, and the balance between joint strength, fabrication complexity, and maintenance.

Choosing the Right Joint for Your Project

Selecting the appropriate joint type depends on factors such as load requirements, material properties, and environmental conditions. Riveted joints offer excellent fatigue resistance and are ideal for structures subjected to dynamic loads, while welded joints provide higher strength and a continuous bond suitable for heavy-duty, static applications. Consider fabrication complexity, inspection methods, and maintenance needs to ensure optimal performance and longevity of the assembled components.

Riveted joint Infographic

libterm.com

libterm.com