Forging enhances metal strength and durability by shaping materials under intense heat and pressure, creating components with superior structural integrity compared to casting or machining. This process improves grain flow and reduces the likelihood of defects, making it ideal for high-stress applications in industries like automotive, aerospace, and construction. Explore the article to discover how forging can optimize your manufacturing processes and product performance.

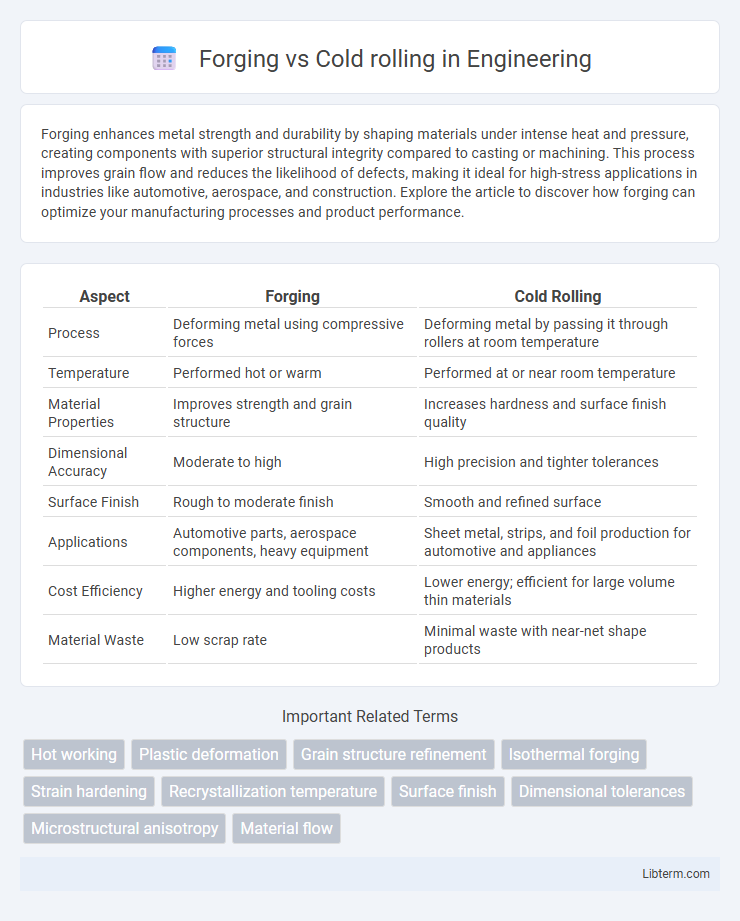

Table of Comparison

| Aspect | Forging | Cold Rolling |

|---|---|---|

| Process | Deforming metal using compressive forces | Deforming metal by passing it through rollers at room temperature |

| Temperature | Performed hot or warm | Performed at or near room temperature |

| Material Properties | Improves strength and grain structure | Increases hardness and surface finish quality |

| Dimensional Accuracy | Moderate to high | High precision and tighter tolerances |

| Surface Finish | Rough to moderate finish | Smooth and refined surface |

| Applications | Automotive parts, aerospace components, heavy equipment | Sheet metal, strips, and foil production for automotive and appliances |

| Cost Efficiency | Higher energy and tooling costs | Lower energy; efficient for large volume thin materials |

| Material Waste | Low scrap rate | Minimal waste with near-net shape products |

Introduction to Forging and Cold Rolling

Forging transforms metal through compressive forces, enhancing strength and grain structure by shaping heated workpieces using hammers or presses. Cold rolling deforms metal at room temperature, improving surface finish and mechanical properties by passing material through rollers to reduce thickness. Both processes impact metal's microstructure and mechanical characteristics, with forging favoring toughness and cold rolling emphasizing dimensional accuracy.

Definition and Overview of Forging

Forging is a manufacturing process that involves shaping metal using localized compressive forces, typically delivered through a hammer or die, to improve material strength and grain structure. Unlike cold rolling, which shapes metal at room temperature by passing it through rollers, forging is often performed at elevated temperatures to increase ductility and reduce the risk of cracking. This process results in components with superior mechanical properties, enhanced fatigue resistance, and better structural integrity for industrial applications.

Definition and Overview of Cold Rolling

Cold rolling is a metalworking process where metal is passed through rollers at temperatures below its recrystallization point to reduce thickness, improve surface finish, and enhance mechanical properties. Unlike forging, which involves shaping metal using compressive forces at high temperatures, cold rolling maintains the metal's structural integrity and increases strength through strain hardening. This process is essential in producing sheets, strips, and foils with precise dimensions and superior surface quality for industrial applications.

Key Differences Between Forging and Cold Rolling

Forging involves shaping metal using compressive forces at high temperatures, resulting in improved grain structure and enhanced mechanical properties. Cold rolling, performed at room temperature, reduces metal thickness through successive passes, increasing surface finish quality and dimensional accuracy but may induce strain hardening. Key differences include forging's ability to produce complex, high-strength parts versus cold rolling's efficiency in producing uniform sheets and strips with improved surface finish.

Material Properties: Forging vs Cold Rolling

Forging enhances material properties by refining grain structure, increasing strength, toughness, and fatigue resistance through plastic deformation at elevated temperatures. Cold rolling improves surface finish and dimensional accuracy while increasing yield strength and hardness due to work hardening, but it may reduce ductility compared to forging. Forged components typically exhibit superior impact resistance and uniform mechanical properties, whereas cold-rolled materials excel in precise tolerances and smooth surface characteristics.

Applications and Industry Use Cases

Forging is widely used in heavy industries such as automotive, aerospace, and construction for manufacturing high-strength components like crankshafts, gears, and turbine blades due to its superior mechanical properties and grain structure refinement. Cold rolling is prevalent in the production of thin metal sheets and strips used in consumer electronics, appliance manufacturing, and architectural applications, offering excellent surface finish and dimensional accuracy. Each process is selected based on the required mechanical strength, precision, and material form needed in specific industrial applications.

Advantages of Forging

Forging offers superior strength and durability by aligning metal grain structures, resulting in enhanced mechanical properties compared to cold rolling. The process reduces the risk of internal defects and improves fatigue resistance, making forged components ideal for high-stress applications. Additionally, forging allows for customized shapes with better dimensional accuracy and lower waste, optimizing material usage and performance.

Advantages of Cold Rolling

Cold rolling offers superior surface finish and tighter dimensional tolerances compared to forging, making it ideal for producing high-precision metal sheets and strips. The process enhances material strength through strain hardening while improving flatness and surface texture. Cold rolling reduces the need for machining and finishing, resulting in cost savings and increased production efficiency in manufacturing.

Limitations and Challenges of Each Process

Forging faces limitations such as higher tooling costs, difficulty in achieving precise dimensions, and challenges with complex geometries, which can restrict its use in producing intricate parts. Cold rolling presents challenges including residual stresses that require stress-relieving treatments, limited thickness reduction per pass, and reduced ductility leading to potential cracking during processing. Both processes require careful control of parameters to balance strength enhancement with material integrity and dimensional accuracy.

Choosing the Right Process: Forging or Cold Rolling

Choosing between forging and cold rolling depends on the desired mechanical properties and final application. Forging offers superior strength and structural integrity by shaping metal under high pressure, ideal for heavy-duty components like crankshafts and aircraft parts. Cold rolling enhances surface finish and dimensional accuracy, making it suitable for thin sheets and precision parts used in automotive panels and appliances.

Forging Infographic

libterm.com

libterm.com