Size tolerance defines the allowable variation in a part's dimensions, ensuring components fit and function correctly in assemblies. Precise size tolerance controls reduce manufacturing errors, improve product quality, and minimize rework costs. Discover how understanding size tolerance can enhance your production process in the following article.

Table of Comparison

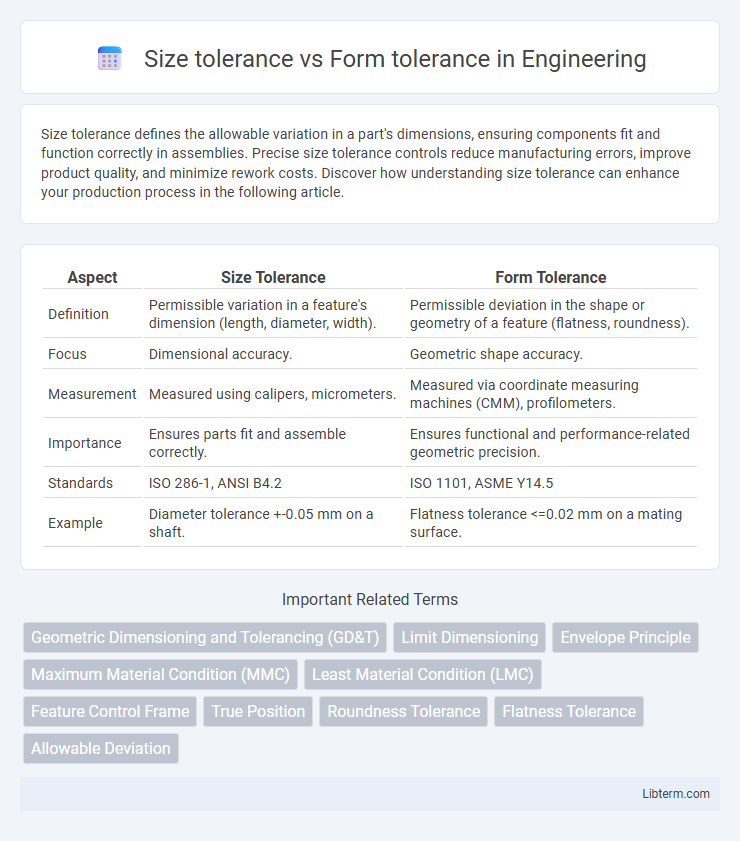

| Aspect | Size Tolerance | Form Tolerance |

|---|---|---|

| Definition | Permissible variation in a feature's dimension (length, diameter, width). | Permissible deviation in the shape or geometry of a feature (flatness, roundness). |

| Focus | Dimensional accuracy. | Geometric shape accuracy. |

| Measurement | Measured using calipers, micrometers. | Measured via coordinate measuring machines (CMM), profilometers. |

| Importance | Ensures parts fit and assemble correctly. | Ensures functional and performance-related geometric precision. |

| Standards | ISO 286-1, ANSI B4.2 | ISO 1101, ASME Y14.5 |

| Example | Diameter tolerance +-0.05 mm on a shaft. | Flatness tolerance <=0.02 mm on a mating surface. |

Understanding Size Tolerance: Definition and Importance

Size tolerance defines the permissible limits of variation in a physical dimension, ensuring that parts fit and function properly within an assembly. Precise size tolerance control prevents mechanical failures, reduces manufacturing costs, and enhances product reliability. Understanding size tolerance is crucial for maintaining quality standards and achieving consistent performance in engineering applications.

What is Form Tolerance? Key Concepts Explained

Form tolerance refers to the allowable deviation from the ideal geometric shape of a feature on a manufactured part, ensuring the feature maintains its intended form within specified limits. It controls imperfections such as flatness, straightness, circularity, and cylindricity, which affect the shape but not the size of the feature. Unlike size tolerance that limits dimensional variations, form tolerance ensures the accuracy of the feature's contour and surface geometry critical for proper function and assembly.

Core Differences Between Size and Form Tolerances

Size tolerance specifies the permissible variation in the physical dimensions of a part, such as length, width, or diameter, ensuring the part fits within exact limits. Form tolerance controls the shape or geometric accuracy of a feature, like flatness, straightness, or roundness, maintaining the intended geometric profile without dimension variations. The core difference lies in size tolerance governing measurable dimensions, whereas form tolerance regulates geometric imperfections independent of size constraints.

When to Apply Size Tolerance in Engineering Drawings

Size tolerance specifies the permissible variation in the physical dimensions of a part, ensuring it fits and functions correctly within an assembly. It is applied when controlling the exact measurement of features such as lengths, diameters, and thicknesses that directly affect part compatibility and performance. Use size tolerance in engineering drawings to guarantee interchangeability and proper assembly of components under varying manufacturing conditions.

Practical Applications of Form Tolerances

Form tolerances control the shape, straightness, flatness, and roundness of individual features, ensuring proper fit and function in precision components like engine parts and aerospace assemblies. Unlike size tolerances, which regulate dimensions, form tolerances guarantee consistent geometry, reducing wear and assembly errors in high-precision manufacturing. Practical applications include controlling surface flatness on machined parts and ensuring roundness in bearings to maintain optimal performance and longevity.

Impact of Size and Form Tolerances on Manufacturing Quality

Size tolerance directly influences the dimensional accuracy of manufactured parts, ensuring they fit within specified limits and function properly in assemblies. Form tolerance controls geometric imperfections such as straightness, flatness, and roundness, impacting the part's shape and surface quality. The combined control of size and form tolerances is crucial to maintaining manufacturing quality by reducing defects, improving interchangeability, and enhancing product reliability.

Inspection Techniques: Measuring Size vs. Form Tolerances

Size tolerance inspection relies on direct measurement tools like calipers, micrometers, and coordinate measuring machines (CMM) to verify dimensions such as length, diameter, and thickness against specified limits. Form tolerance inspection, including flatness, cylindricity, and straightness, requires advanced techniques such as surface profilometers, optical comparators, and laser scanners to detect deviations from ideal geometric shapes. The precision of CMM and 3D scanning technologies enhances the accuracy of form tolerance evaluation by capturing complex surface geometries beyond simple size measurements.

Role of Size and Form Tolerance in GD&T Standards

Size tolerance in GD&T defines the permissible variation in a feature's absolute dimension, ensuring parts fit correctly in assemblies by controlling parameters like diameter, length, or width. Form tolerance regulates the shape of a feature, maintaining geometric integrity such as flatness, straightness, and roundness without reference to other features. Both size and form tolerances are essential in GD&T standards for guaranteeing part functionality, manufacturability, and interchangeability by precisely controlling dimension and geometry.

Common Mistakes in Applying Size and Form Tolerances

Common mistakes in applying size tolerance include confusing it with form tolerance, leading to incorrect specifications that affect part interchangeability and function. Size tolerance strictly controls the allowable variation in dimension, while form tolerance governs shape deviations such as flatness, straightness, or roundness. Misapplication often results in manufacturing errors, increased rework, and non-compliance with geometric dimensioning and tolerancing (GD&T) standards.

Best Practices for Specifying and Controlling Tolerances

Size tolerance controls the allowable variations in the dimensions of a part, ensuring it fits and functions within assembly constraints. Form tolerance defines the permissible deviations in the shape of features, such as flatness, roundness, or straightness, maintaining the part's geometric integrity. Best practices include specifying tighter size tolerances for critical mating surfaces and applying form tolerances judiciously to balance manufacturing feasibility with functional requirements, supported by GD&T standards for clarity and consistency.

Size tolerance Infographic

libterm.com

libterm.com