Gate valves provide reliable shut-off capabilities by lifting a gate out of the fluid path, ensuring minimal pressure drop when fully open. Their durable design is ideal for on/off control in pipelines carrying liquids or gases, as they prevent leakage and maintain a tight seal. Discover how gate valves can optimize your system's performance by reading the full article.

Table of Comparison

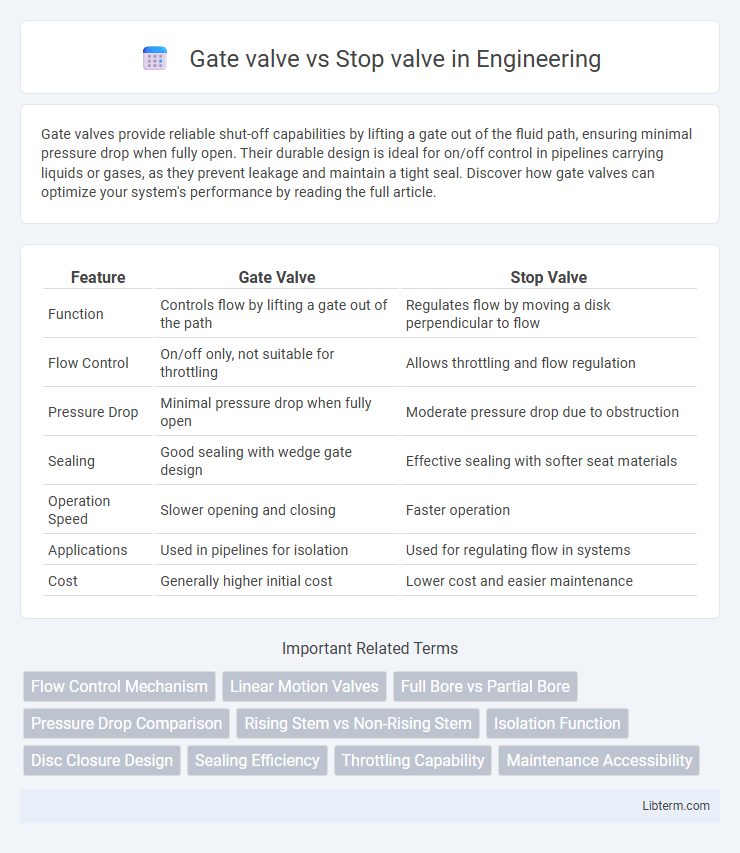

| Feature | Gate Valve | Stop Valve |

|---|---|---|

| Function | Controls flow by lifting a gate out of the path | Regulates flow by moving a disk perpendicular to flow |

| Flow Control | On/off only, not suitable for throttling | Allows throttling and flow regulation |

| Pressure Drop | Minimal pressure drop when fully open | Moderate pressure drop due to obstruction |

| Sealing | Good sealing with wedge gate design | Effective sealing with softer seat materials |

| Operation Speed | Slower opening and closing | Faster operation |

| Applications | Used in pipelines for isolation | Used for regulating flow in systems |

| Cost | Generally higher initial cost | Lower cost and easier maintenance |

Introduction to Gate Valve vs Stop Valve

Gate valves feature a wedge-shaped gate that moves up and down to control fluid flow, providing minimal pressure drop when fully open. Stop valves utilize a plug or disc that rotates or moves perpendicularly to the flow, allowing precise regulation and quick shutoff capabilities. Both valves serve critical roles in pipeline systems, with gate valves preferred for on/off control and stop valves ideal for throttling applications.

Understanding Gate Valves: Design and Function

Gate valves feature a wedge-shaped metal gate that moves vertically to control fluid flow, providing minimal pressure drop and a straight-through passage when fully open. Their design enables reliable shutoff in pipelines carrying liquids, making them ideal for on/off control rather than flow regulation. Typically used in water, oil, and gas industries, gate valves excel in systems requiring tight sealing and durability under high pressure.

Stop Valves Explained: Structure and Operation

Stop valves consist of a movable plug or disc that presses against a seat to regulate fluid flow, offering precise control often utilized in residential and commercial plumbing systems. Their structure includes a spindle, handwheel, and body that work together to lift or lower the disc, effectively stopping or allowing fluid passage. The operation of stop valves is characterized by a linear movement that provides tight sealing and easy maintenance, making them ideal for isolating sections of piping for repair or inspection.

Key Differences Between Gate and Stop Valves

Gate valves provide full flow with minimal pressure drop, making them ideal for on/off control in large diameter pipelines. Stop valves, also known as globe valves, offer precise flow regulation and better throttling capabilities due to their disc and seat design. The main difference lies in gate valves being efficient for isolation, while stop valves excel in flow control and pressure adjustment.

Applications: When to Use Gate vs Stop Valves

Gate valves are ideal for applications requiring minimal pressure drop and full flow, such as water supply systems, oil pipelines, and gas transmission, where the valve remains fully open or closed for long periods. Stop valves suit situations demanding precise flow control and frequent operation, commonly used in domestic plumbing, heating systems, and instrumentation lines where throttling is necessary. Choosing between gate and stop valves depends on whether the priority is tight shutoff with low resistance or accurate flow regulation with ease of operation.

Flow Control Capabilities: Gate vs Stop Valves

Gate valves provide excellent flow control by allowing full unobstructed flow when fully open, making them ideal for on/off operations with minimal pressure drop. Stop valves, also known as globe valves, offer superior throttling capabilities due to their design, enabling precise regulation of flow rates. The choice between gate and stop valves depends on whether the application prioritizes minimal flow resistance or accurate flow control.

Maintenance and Durability Comparison

Gate valves typically require less frequent maintenance due to their simple linear motion and fewer moving parts, making them highly durable in high-pressure environments. Stop valves, with their rotary motion and more complex sealing mechanisms, often need more regular inspection and maintenance to prevent leakage and ensure optimal performance. Durability-wise, gate valves excel in applications with minimal operation cycles, while stop valves are better suited for frequent operation but may experience faster wear over time.

Pros and Cons of Gate Valves

Gate valves provide excellent sealing capabilities, making them ideal for on/off control in pipelines with minimal pressure drop and low flow resistance. However, their slow operation, requirement for full opening or closing to prevent damage, and unsuitability for throttling limit their use in applications needing precise flow regulation. Maintenance can be challenging due to the complex mechanism of the gate, which is prone to wear and corrosion over time.

Advantages and Disadvantages of Stop Valves

Stop valves offer precise flow control and quick shut-off capabilities, making them ideal for systems requiring frequent adjustments or emergency stops. However, they tend to have higher pressure drops compared to gate valves and may require more maintenance due to their moving parts and seal wear. While stop valves excel in throttling applications, their complexity and potential for leakage make them less suitable for full bore flow needs.

Choosing the Right Valve for Your System

Selecting the right valve for your system depends on the application requirements and flow control precision. Gate valves offer minimal pressure drop and are ideal for on/off control in large pipe diameters, while stop valves provide finer throttling capabilities for regulating flow in smaller or more sensitive systems. Consider factors such as valve size, pressure rating, and the need for flow adjustment to ensure optimal performance and longevity.

Gate valve Infographic

libterm.com

libterm.com