Fatigue strength refers to a material's ability to withstand cyclic loading without failing over time, a critical factor in engineering design and safety evaluations. It is essential for predicting the lifespan of components subjected to repeated stress, such as bridges, aircraft, and machinery parts. Explore the rest of the article to understand how fatigue strength impacts your material selection and product durability.

Table of Comparison

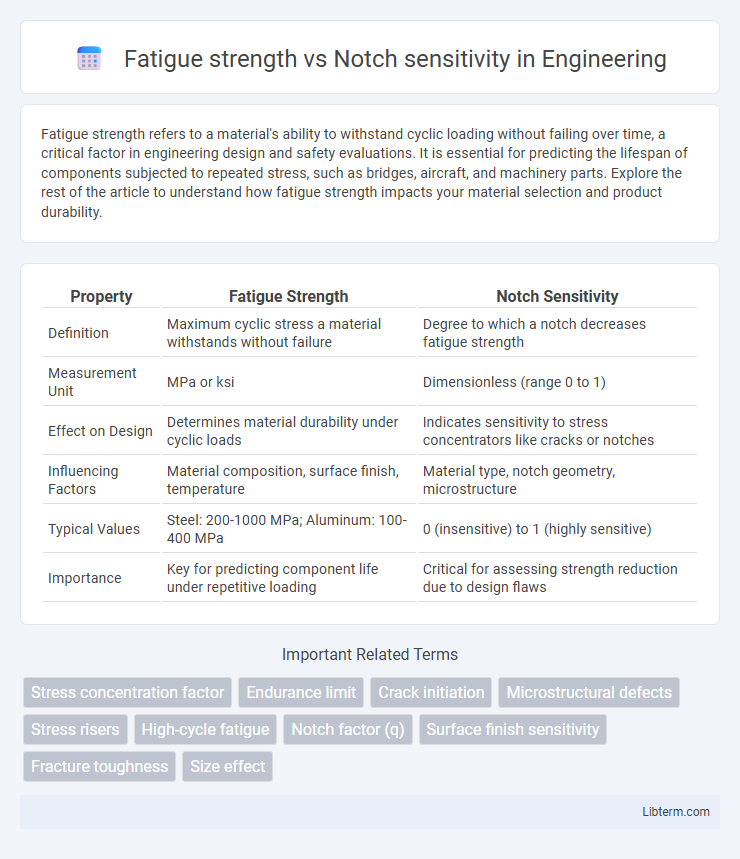

| Property | Fatigue Strength | Notch Sensitivity |

|---|---|---|

| Definition | Maximum cyclic stress a material withstands without failure | Degree to which a notch decreases fatigue strength |

| Measurement Unit | MPa or ksi | Dimensionless (range 0 to 1) |

| Effect on Design | Determines material durability under cyclic loads | Indicates sensitivity to stress concentrators like cracks or notches |

| Influencing Factors | Material composition, surface finish, temperature | Material type, notch geometry, microstructure |

| Typical Values | Steel: 200-1000 MPa; Aluminum: 100-400 MPa | 0 (insensitive) to 1 (highly sensitive) |

| Importance | Key for predicting component life under repetitive loading | Critical for assessing strength reduction due to design flaws |

Understanding Fatigue Strength in Engineering Materials

Fatigue strength refers to the maximum stress a material can withstand for a specified number of cycles without failure, crucial in engineering materials subjected to repetitive loading. Notch sensitivity quantifies how the presence of geometric discontinuities, such as cracks or grooves, reduces the fatigue strength by concentrating stress locally. Understanding the interplay between fatigue strength and notch sensitivity helps engineers design components that resist crack initiation and propagation, optimizing durability and preventing unexpected failures.

Defining Notch Sensitivity: Causes and Implications

Notch sensitivity quantifies a material's susceptibility to stress concentration effects caused by geometric discontinuities like notches or grooves, which significantly reduce fatigue strength by amplifying local stresses. It primarily arises from microstructural heterogeneity and crack initiation sites within the material, impacting durability and failure modes under cyclic loading conditions. Understanding notch sensitivity is crucial for accurately predicting fatigue life and optimizing component design to mitigate premature fracture risks.

The Relationship Between Fatigue Strength and Notch Sensitivity

Fatigue strength decreases as notch sensitivity increases because stress concentrations at notches amplify cyclic stresses, accelerating crack initiation and propagation. Materials with high notch sensitivity exhibit significant reductions in fatigue strength when notches or geometric discontinuities are present. Understanding the relationship between fatigue strength and notch sensitivity is essential for designing components that resist failure under cyclic loading conditions.

Factors Affecting Fatigue Strength in Metals

Fatigue strength in metals is significantly influenced by notch sensitivity, which describes a material's tendency to experience stress concentration around geometric discontinuities, thereby reducing its fatigue life. Factors affecting fatigue strength include surface finish, as rough surfaces increase stress concentration; environmental conditions, such as corrosion that can initiate cracks; microstructural properties, including grain size and phase distribution; and residual stresses introduced during manufacturing processes. The interaction between these factors and notch sensitivity determines the crack initiation and propagation rate, critically impacting the overall durability of metal components under cyclic loading.

Notch Effects: Stress Concentrations and Crack Initiation

Notch sensitivity significantly influences fatigue strength by increasing stress concentrations at geometric discontinuities, which act as initiation sites for cracks under cyclic loading. The presence of notches raises localized stress intensity, reducing a material's effective fatigue limit compared to smooth specimens. Understanding notch effects is crucial for predicting crack initiation and improving fatigue resistance in engineering components.

Material Selection: Balancing Fatigue Strength and Notch Sensitivity

Material selection demands careful balancing of fatigue strength and notch sensitivity to maximize component durability under cyclic loading. Materials with high fatigue strength often exhibit low notch sensitivity, reducing stress concentration effects at geometric discontinuities and extending service life. Engineers prioritize alloys or composites with optimized microstructures to enhance resistance to crack initiation and propagation around notches, improving overall performance in fatigue-prone applications.

Testing Methods for Fatigue Strength and Notch Sensitivity

Testing methods for fatigue strength often involve rotating bending, axial loading, or flexural fatigue tests to determine the material's resistance to cyclic stresses. Notch sensitivity is typically evaluated using notched specimens subjected to fatigue testing, such as standardized Charpy or fatigue crack growth tests, to measure the reduction in fatigue life caused by stress concentrators. Advanced techniques like strain gauge measurements and fracture mechanics approaches help quantify the relationship between notch geometry, stress concentration, and fatigue performance.

Design Strategies to Reduce Notch Sensitivity

Design strategies to reduce notch sensitivity focus on optimizing material selection and geometric features to minimize stress concentration effects. Incorporating smooth transitions, fillets, and reducing sharp corners in component design effectively lowers localized stress, enhancing fatigue strength. Surface treatments such as shot peening and carburizing improve surface integrity, increasing resistance to crack initiation at notches.

Case Studies: Failures Due to Fatigue and Notch Effects

Fatigue strength significantly decreases in materials with high notch sensitivity, as stress concentrations at notches act as initiation sites for crack propagation. Case studies involving aerospace aluminum alloys reveal premature failures where notches amplified cyclic stresses, reducing fatigue life by over 40%. In automotive steel components, notch-induced fatigue failures are linked to microstructural inhomogeneities, underscoring the critical need to consider notch geometry in design for fatigue resistance.

Future Trends in Enhancing Fatigue Resistance and Reducing Notch Sensitivity

Advancements in nanostructured materials and surface engineering techniques are revolutionizing fatigue strength by minimizing notch sensitivity in critical components. Emerging additive manufacturing processes enable the design of optimized microstructures that enhance crack initiation resistance and improve overall fatigue life. Integration of machine learning algorithms for predictive modeling accelerates the development of fatigue-resistant materials tailored to complex service conditions, fostering innovation in aerospace, automotive, and biomedical industries.

Fatigue strength Infographic

libterm.com

libterm.com