Robust control ensures system stability and performance despite uncertainties and disturbances, making it essential for complex engineering applications. It employs mathematical models and optimization techniques to design controllers that can handle variations within specified bounds. Explore this article to learn how robust control can enhance the reliability and efficiency of your systems.

Table of Comparison

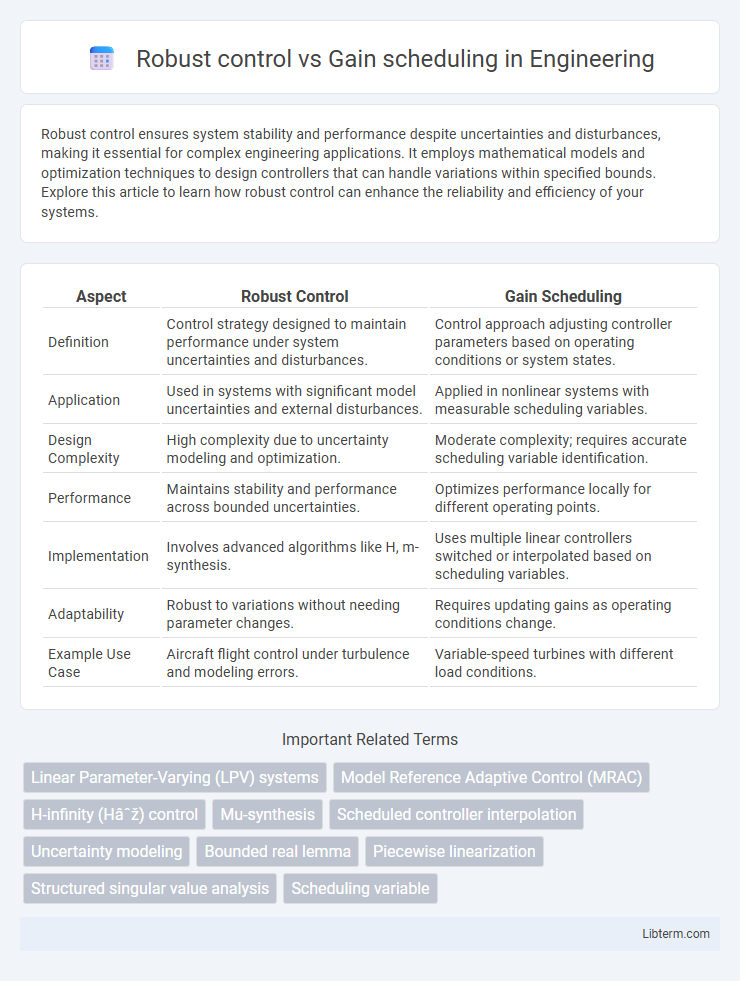

| Aspect | Robust Control | Gain Scheduling |

|---|---|---|

| Definition | Control strategy designed to maintain performance under system uncertainties and disturbances. | Control approach adjusting controller parameters based on operating conditions or system states. |

| Application | Used in systems with significant model uncertainties and external disturbances. | Applied in nonlinear systems with measurable scheduling variables. |

| Design Complexity | High complexity due to uncertainty modeling and optimization. | Moderate complexity; requires accurate scheduling variable identification. |

| Performance | Maintains stability and performance across bounded uncertainties. | Optimizes performance locally for different operating points. |

| Implementation | Involves advanced algorithms like H, m-synthesis. | Uses multiple linear controllers switched or interpolated based on scheduling variables. |

| Adaptability | Robust to variations without needing parameter changes. | Requires updating gains as operating conditions change. |

| Example Use Case | Aircraft flight control under turbulence and modeling errors. | Variable-speed turbines with different load conditions. |

Introduction to Robust Control and Gain Scheduling

Robust control focuses on maintaining system stability and performance despite uncertainties and disturbances by designing controllers that account for worst-case scenarios within specified bounds. Gain scheduling adjusts controller parameters dynamically based on measurable operating conditions, enabling effective management of nonlinear or time-varying systems across different regimes. Both methods enhance control system reliability, yet robust control emphasizes global stability under uncertainty, while gain scheduling optimizes performance through parameter adaptation.

Key Concepts and Definitions

Robust control ensures system stability and performance despite uncertainties and variations in model parameters by designing controllers that manage worst-case scenarios within a defined uncertainty set. Gain scheduling adapts controller parameters based on measurable operating conditions, effectively creating a family of linear controllers scheduled according to system states or external variables. Key concepts include robustness metrics like structured singular value (m) for robust control and scheduling variables for gain scheduling, highlighting their fundamental differences in handling nonlinearity and uncertainty.

Fundamental Differences Between Robust Control and Gain Scheduling

Robust control designs a single controller that maintains system stability and performance despite uncertainties and model variations, ensuring uniform behavior across all operating conditions. Gain scheduling adjusts controller parameters dynamically based on measurable system states or operating points, tailoring control actions to varying conditions but relying on accurate scheduling variables and models. The fundamental difference lies in robustness to uncertainty--robust control inherently manages unmodeled dynamics, whereas gain scheduling depends on predefined parameter maps and may fail if system dynamics deviate beyond those maps.

Applications in Modern Control Systems

Robust control techniques are widely applied in aerospace and automotive systems to ensure stability and performance despite model uncertainties and external disturbances. Gain scheduling is extensively used in nonlinear systems such as aircraft flight control and chemical process control, adapting controller parameters based on operating conditions. Modern control systems increasingly integrate robust control with gain scheduling to handle complex, time-varying dynamics while maintaining reliability and efficiency.

Strengths of Robust Control Strategies

Robust control strategies excel at maintaining system stability and performance despite significant model uncertainties and external disturbances. They provide guaranteed performance margins by accounting for worst-case scenarios, making them ideal for systems with high variability or unpredicted dynamics. This approach reduces the need for frequent controller retuning, enhancing reliability in complex or safety-critical applications.

Advantages and Limitations of Gain Scheduling

Gain scheduling offers the advantage of handling nonlinear systems by switching between linear controllers tuned for specific operating points, enabling effective performance across varying conditions. Its main limitations include complexity in designing multiple controllers, difficulty in ensuring smooth transitions between schedules, and potential instability if parameter changes are abrupt or unmodeled dynamics arise. Robust control provides inherent stability margins against uncertainties but may be conservative, whereas gain scheduling delivers tailored control actions at the cost of increased design effort and potential implementation challenges.

Comparative Analysis: Performance and Adaptability

Robust control ensures consistent performance across a wide range of uncertainties by designing a single controller that maintains stability and performance under all expected conditions. Gain scheduling adapts controller parameters based on real-time measurements of system states or operating conditions, providing optimal performance in varying environments but requiring accurate system models for each operating point. While robust control excels in worst-case scenarios with guaranteed stability, gain scheduling offers superior adaptability and improved nominal performance when system dynamics change predictably.

Typical Use Cases and Industry Examples

Robust control is widely employed in aerospace and automotive industries for systems requiring stability under varying uncertainties, such as flight control systems and autonomous vehicles. Gain scheduling is commonly used in chemical process control and robotics, where system dynamics change predictably with operating conditions, enabling smooth transitions between predefined linear controllers. Typical use cases highlight robust control's strength in handling unmodeled disturbances, while gain scheduling excels in applications with structured and measurable parameter variations.

Selection Criteria: When to Choose Each Approach

Robust control is preferred for systems with significant uncertainty and varying parameters where guaranteed performance and stability across a broad range of conditions are critical. Gain scheduling is suitable for systems operating over distinct, well-defined regimes where real-time adjustment of controller parameters based on measurable variables can optimize performance. Selection depends on system complexity, uncertainty levels, and the availability of accurate models for different operating points.

Future Trends in Control System Design

Future trends in control system design emphasize integrating robust control with adaptive gain scheduling to enhance system performance under uncertainty and varying operating conditions. Advances in machine learning and artificial intelligence enable predictive tuning of gain-scheduled controllers, improving adaptability while maintaining robustness. The convergence of these methodologies facilitates real-time optimization and resilience in complex, nonlinear, and time-varying systems across aerospace, automotive, and industrial applications.

Robust control Infographic

libterm.com

libterm.com