Dispersion strengthening enhances the mechanical properties of materials by uniformly distributing fine, stable particles within the metal matrix, which impedes dislocation movement and increases strength. This technique is essential in producing high-performance alloys used in aerospace, automotive, and structural applications due to their improved resistance to deformation at elevated temperatures. Explore the rest of the article to understand how dispersion strengthening can improve your materials' performance and durability.

Table of Comparison

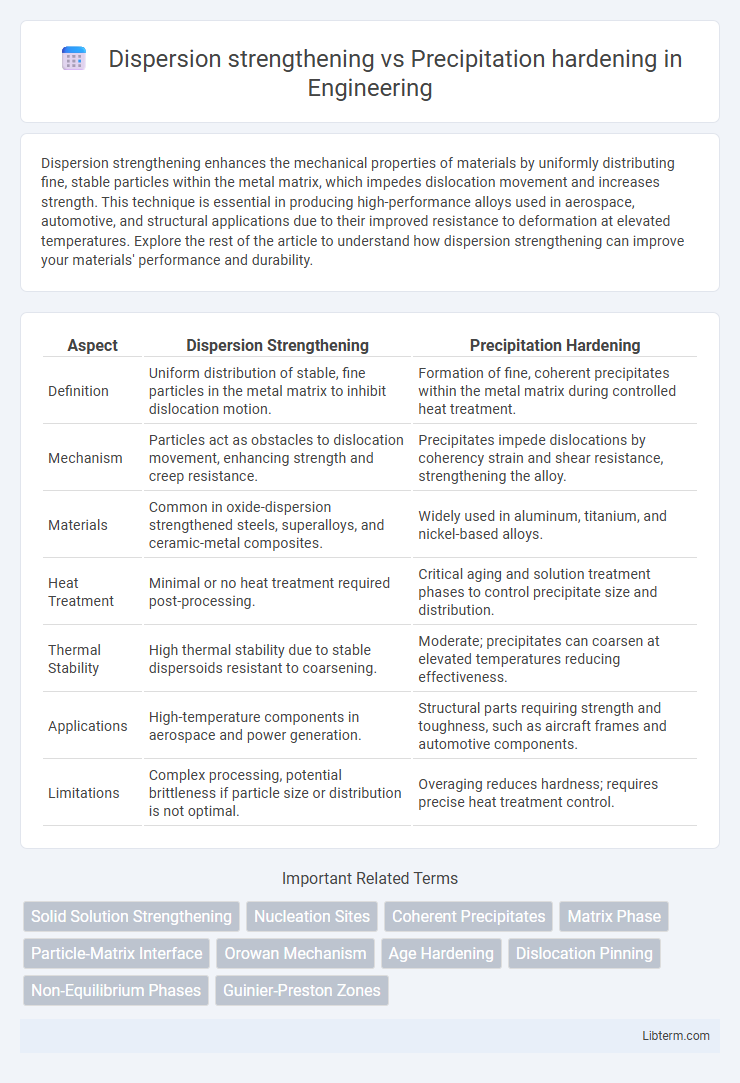

| Aspect | Dispersion Strengthening | Precipitation Hardening |

|---|---|---|

| Definition | Uniform distribution of stable, fine particles in the metal matrix to inhibit dislocation motion. | Formation of fine, coherent precipitates within the metal matrix during controlled heat treatment. |

| Mechanism | Particles act as obstacles to dislocation movement, enhancing strength and creep resistance. | Precipitates impede dislocations by coherency strain and shear resistance, strengthening the alloy. |

| Materials | Common in oxide-dispersion strengthened steels, superalloys, and ceramic-metal composites. | Widely used in aluminum, titanium, and nickel-based alloys. |

| Heat Treatment | Minimal or no heat treatment required post-processing. | Critical aging and solution treatment phases to control precipitate size and distribution. |

| Thermal Stability | High thermal stability due to stable dispersoids resistant to coarsening. | Moderate; precipitates can coarsen at elevated temperatures reducing effectiveness. |

| Applications | High-temperature components in aerospace and power generation. | Structural parts requiring strength and toughness, such as aircraft frames and automotive components. |

| Limitations | Complex processing, potential brittleness if particle size or distribution is not optimal. | Overaging reduces hardness; requires precise heat treatment control. |

Introduction to Strengthening Mechanisms

Dispersion strengthening involves the reinforcement of a metal matrix by uniformly distributed hard particles that obstruct dislocation motion, enhancing strength without significantly compromising ductility. Precipitation hardening, also called age hardening, relies on the formation of finely distributed secondary phases within the alloy matrix through controlled heat treatments to impede dislocation movement and increase yield strength. Both mechanisms are critical in materials engineering for improving mechanical properties by manipulating microstructural features to resist plastic deformation.

Overview of Dispersion Strengthening

Dispersion strengthening enhances material strength by uniformly distributing fine, stable particles within the metal matrix, effectively impeding dislocation motion and improving high-temperature performance. These dispersed particles are typically oxides or carbides that remain stable under thermal exposure, maintaining strength without significant coarsening. Compared to precipitation hardening, which relies on controlled formation and growth of second-phase particles through heat treatment, dispersion strengthening offers superior creep resistance and dimensional stability in extreme environments.

Understanding Precipitation Hardening

Precipitation hardening enhances material strength by forming finely dispersed secondary phase particles within the metal matrix, which obstruct dislocation movement more effectively than dispersion strengthening's stable oxide or carbide particles. This process involves solution treatment, quenching, and aging to control the size and distribution of precipitates like Guinier-Preston zones or intermetallic compounds. Understanding precipitation hardening requires analyzing the kinetics of nucleation and growth of precipitates, as well as their interaction with the metal's crystal lattice to optimize mechanical properties such as yield strength and hardness.

Key Differences Between Dispersion and Precipitation Strengthening

Dispersion strengthening involves the uniform distribution of stable, inert particles within a metal matrix to hinder dislocation movement, while precipitation hardening relies on the formation of fine, coherent precipitates through controlled heat treatment processes. Dispersion strengthening typically uses particles that do not dissolve during processing, providing high-temperature stability, whereas precipitation hardening precipitates form and dissolve during thermal cycles, allowing tunable mechanical properties. The key difference lies in the nature and behavior of the strengthening particles: dispersion strengthening particles remain stable and non-coherent, while precipitation hardening depends on precipitation and dissolution of coherent phases to enhance strength.

Mechanisms of Particle Reinforcement

Dispersion strengthening relies on the uniform distribution of stable, non-coherent particles such as oxides or carbides within the metal matrix, which impede dislocation motion by acting as physical barriers. Precipitation hardening involves the formation of coherent or semi-coherent fine precipitate phases through controlled heat treatment, which interact with dislocations by cutting or bowing mechanisms to increase yield strength. The key difference lies in particle stability and coherence: dispersion particles remain unaffected by thermal exposure, providing consistent reinforcement, whereas precipitates can evolve with temperature changes, influencing their hardening effectiveness.

Material Systems and Examples

Dispersion strengthening primarily utilizes stable, non-coherent particles such as oxides in materials like ODS (oxide dispersion-strengthened) steels and nickel-based superalloys, where fine ceramic particles enhance high-temperature strength and creep resistance. Precipitation hardening relies on the formation of coherent, finely dispersed precipitates within the matrix, commonly observed in aluminum alloys (e.g., 2024, 7075 series), nickel-based superalloys (INCONEL), and titanium alloys, which improve yield strength through controlled aging processes. Both mechanisms improve mechanical properties but differ mainly by particle stability and coherence, influencing their applicability to various high-performance material systems.

Effects on Mechanical Properties

Dispersion strengthening enhances mechanical properties by introducing stable, finely dispersed particles that obstruct dislocation motion, significantly increasing yield strength and creep resistance at high temperatures. Precipitation hardening relies on the formation of coherent or semi-coherent precipitates during heat treatment, which effectively impede dislocation movement and improve tensile strength and hardness. The major difference lies in thermal stability: dispersion strengthening offers superior high-temperature performance, whereas precipitation hardening provides higher peak strength but may suffer from overaging.

Industrial Applications and Use Cases

Dispersion strengthening is widely used in aerospace and power generation industries due to its ability to enhance high-temperature creep resistance by uniformly distributing stable oxide particles within metal matrices like ODS (Oxide Dispersion Strengthened) alloys. Precipitation hardening is prevalent in automotive and aerospace sectors where aluminum, titanium, and nickel-based alloys undergo controlled heat treatments to form fine, dispersed precipitates that improve yield strength and fatigue resistance. Industrial applications leverage dispersion strengthening for long-term stability in extreme environments, while precipitation hardening is favored for parts requiring precise mechanical properties and manufacturability through aging processes.

Limitations and Challenges

Dispersion strengthening faces limitations due to particle coarsening at high temperatures, leading to reduced effectiveness in long-term applications. Precipitation hardening challenges include the precise control of aging time and temperature to avoid over-aging, which softens the material and diminishes mechanical properties. Both methods require careful microstructural engineering to balance strength and ductility, with dispersion strengthening often limited by the thermal stability of the dispersoids, while precipitation hardening is constrained by the solubility limits and nucleation kinetics of precipitates.

Future Trends in Advanced Strengthening Techniques

Dispersion strengthening techniques, utilizing stable oxide particles, are evolving towards nanoscale distributions for enhanced thermal stability and mechanical performance in high-temperature applications. Precipitation hardening research focuses on novel alloy compositions and heat treatment processes to optimize precipitate size and distribution, improving strength and ductility in aerospace and automotive materials. Future trends emphasize integrating machine learning and additive manufacturing to tailor microstructures and achieve superior performance through controlled dispersion and precipitation mechanisms.

Dispersion strengthening Infographic

libterm.com

libterm.com