Cam-followers provide precise motion control by converting rotary motion into linear movement, making them essential in automation and machinery applications. Their robust design ensures durability and minimal maintenance even under heavy loads and high speeds. Discover how integrating cam-followers can enhance your system's performance by reading the full article.

Table of Comparison

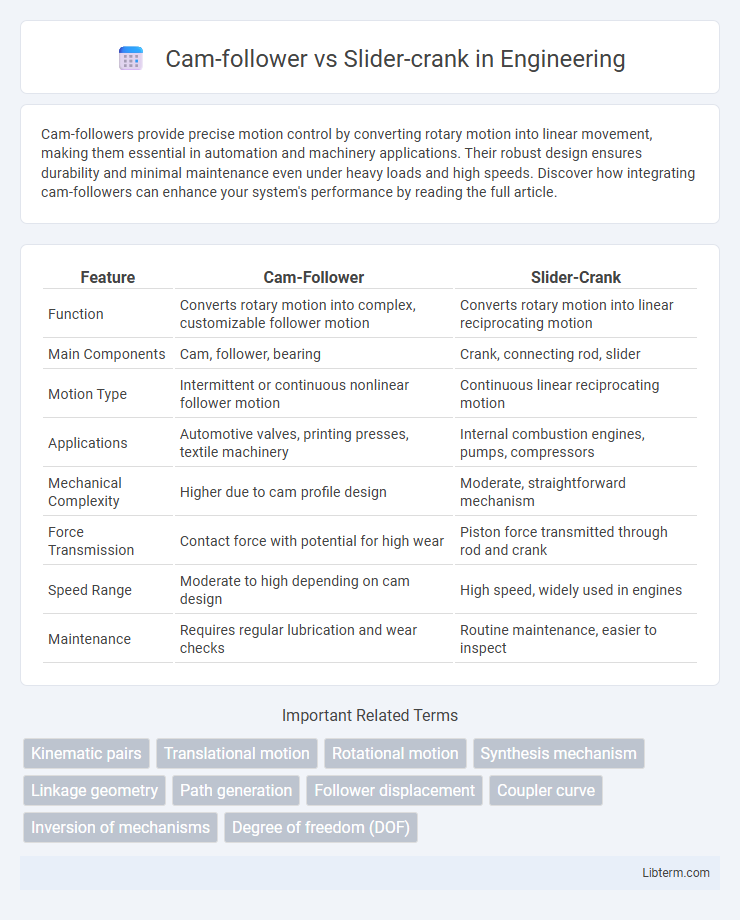

| Feature | Cam-Follower | Slider-Crank |

|---|---|---|

| Function | Converts rotary motion into complex, customizable follower motion | Converts rotary motion into linear reciprocating motion |

| Main Components | Cam, follower, bearing | Crank, connecting rod, slider |

| Motion Type | Intermittent or continuous nonlinear follower motion | Continuous linear reciprocating motion |

| Applications | Automotive valves, printing presses, textile machinery | Internal combustion engines, pumps, compressors |

| Mechanical Complexity | Higher due to cam profile design | Moderate, straightforward mechanism |

| Force Transmission | Contact force with potential for high wear | Piston force transmitted through rod and crank |

| Speed Range | Moderate to high depending on cam design | High speed, widely used in engines |

| Maintenance | Requires regular lubrication and wear checks | Routine maintenance, easier to inspect |

Introduction to Cam-Follower and Slider-Crank Mechanisms

Cam-follower mechanisms consist of a rotating or sliding cam that drives a follower, converting rotary motion into linear or oscillatory movement crucial in automated machinery and engine valve systems. Slider-crank mechanisms convert rotary motion into linear motion or vice versa, commonly found in internal combustion engines, pumps, and compressors, where a crank rotates to drive a slider along a fixed path. Both mechanisms play essential roles in mechanical design by providing precise motion control, with cam-followers emphasizing variable motion profiles and slider-cranks focusing on cyclical linear movements.

Fundamental Principles of Cam-Follower Systems

Cam-follower systems operate on the fundamental principle of converting rotary motion into linear motion through a cam profile that directly drives the follower, ensuring precise displacement and timing control. The cam's shape determines the follower's motion characteristics, such as dwell, rise, and return periods, enabling customized motion profiles. In contrast, slider-crank mechanisms utilize a rotary crank linked to a sliding follower through a connecting rod, primarily converting rotary motion into reciprocating linear motion with fixed kinematic constraints.

Core Concepts of Slider-Crank Mechanisms

The slider-crank mechanism converts rotational motion into reciprocating linear motion through a crank, connecting rod, and slider, enabling efficient power transmission in engines and compressors. The core concepts involve the precise kinematic relationship between the crank's rotation angle and the slider's linear displacement, governed by geometric constraints and link lengths. This mechanism ensures smooth motion transfer and force distribution, contrasting with cam-follower systems that rely on cam profiles to generate specific motion patterns.

Mechanical Structure Comparison

The cam-follower mechanism utilizes a rotating cam to convert rotary motion into linear motion, featuring a cam profile that directly interacts with a follower, resulting in precise motion control and reduced backlash. In contrast, the slider-crank mechanism employs a crank and connecting rod to transform rotary motion into reciprocal linear motion of a slider, characterized by its simple pivot joints and straightforward assembly. The cam-follower system typically offers more complex motion profiles and higher precision, whereas the slider-crank mechanism prioritizes robustness and ease of manufacture in mechanical structures.

Motion Characteristics and Output Differences

Cam-follower mechanisms convert rotary motion into complex, non-uniform follower displacement, enabling customized motion profiles essential for automated machinery and indexing devices. Slider-crank mechanisms transform rotary motion into linear reciprocating motion with a consistent stroke length, commonly used in engines and pumps for predictable, smooth output. The cam-follower excels in precise control of acceleration and dwell periods, while the slider-crank provides reliable, simple harmonic motion with high force transmission efficiency.

Application Areas and Industry Uses

Cam-follower mechanisms are widely used in automated manufacturing systems, packaging machines, and textile machinery due to their precise motion control and durability. Slider-crank mechanisms dominate automotive engines, compressors, and reciprocating pumps where converting rotational motion to linear motion is essential. Both play crucial roles in robotics, with cam-followers enabling intricate path control and slider-cranks providing efficient power transmission.

Advantages of Cam-Follower Mechanisms

Cam-follower mechanisms offer superior precision in motion control and can achieve complex, non-linear movement profiles more easily than slider-crank systems. Their compact design reduces wear and maintenance by minimizing sliding friction, enhancing durability in high-speed or high-load applications. These mechanisms also provide greater flexibility in customizing follower motion, leading to improved efficiency and smoother operation in automated machinery.

Benefits of Slider-Crank Mechanisms

Slider-crank mechanisms offer precise linear motion conversion from rotational input, enhancing efficiency in engine pistons and compressors. Their robust design ensures high load capacity and durability under cyclical stresses, reducing maintenance costs and downtime. Compact configuration allows integration in tight spaces, optimizing mechanical system layout and performance.

Limitations and Challenges of Each System

Cam-follower mechanisms face limitations in high-speed applications due to increased friction and wear from continuous contact between the cam profile and follower, resulting in reduced durability and the need for frequent maintenance. Slider-crank systems encounter challenges related to higher inertial forces and vibration at increased speeds, leading to potential fatigue failure in connecting rods and crankshafts. Both systems require careful material selection and precise lubrication management to mitigate mechanical stress and enhance operational longevity.

Criteria for Selecting the Right Mechanism

Selecting the right mechanism between a cam-follower and slider-crank depends on factors such as motion precision, load capacity, and complexity of the desired output. Cam-follower systems excel in applications requiring complex, non-uniform motion profiles and high positional accuracy, while slider-crank mechanisms offer simpler, uniform reciprocating motion with higher mechanical efficiency for heavy loads. Considerations include the nature of motion, space constraints, maintenance requirements, and application-specific force transmission to optimize performance and durability.

Cam-follower Infographic

libterm.com

libterm.com