Laser welding offers precise and efficient joining of metals with minimal distortion and high repeatability. This technique utilizes a concentrated laser beam to melt and fuse materials, making it ideal for industries requiring strong, clean welds such as automotive and aerospace. Explore the rest of this article to discover how laser welding can enhance your manufacturing processes.

Table of Comparison

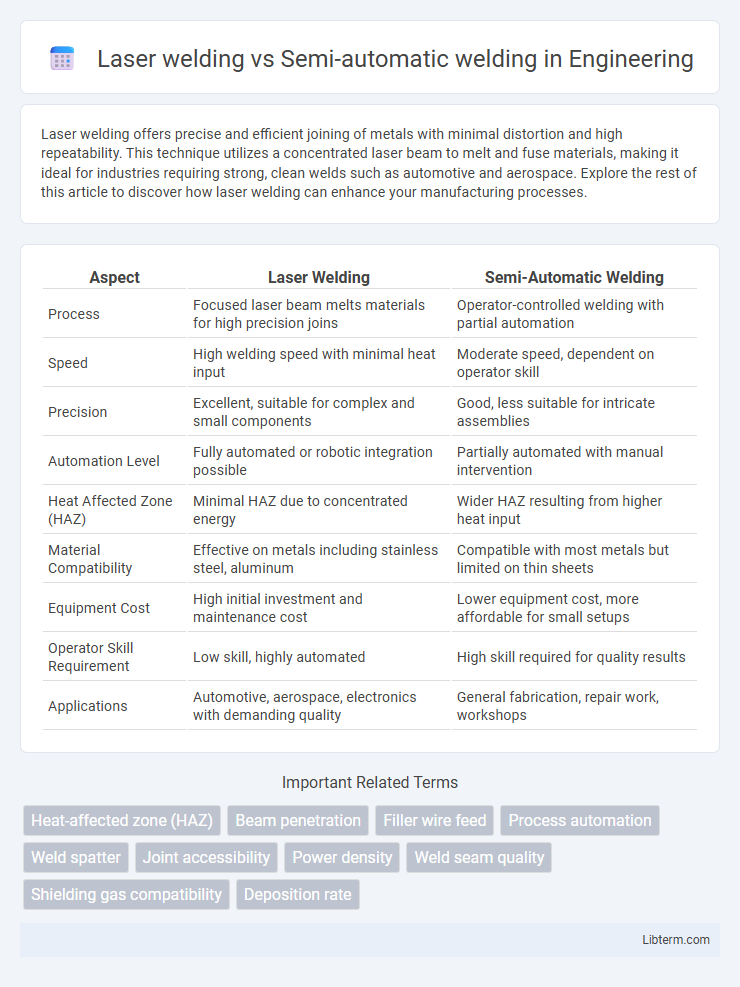

| Aspect | Laser Welding | Semi-Automatic Welding |

|---|---|---|

| Process | Focused laser beam melts materials for high precision joins | Operator-controlled welding with partial automation |

| Speed | High welding speed with minimal heat input | Moderate speed, dependent on operator skill |

| Precision | Excellent, suitable for complex and small components | Good, less suitable for intricate assemblies |

| Automation Level | Fully automated or robotic integration possible | Partially automated with manual intervention |

| Heat Affected Zone (HAZ) | Minimal HAZ due to concentrated energy | Wider HAZ resulting from higher heat input |

| Material Compatibility | Effective on metals including stainless steel, aluminum | Compatible with most metals but limited on thin sheets |

| Equipment Cost | High initial investment and maintenance cost | Lower equipment cost, more affordable for small setups |

| Operator Skill Requirement | Low skill, highly automated | High skill required for quality results |

| Applications | Automotive, aerospace, electronics with demanding quality | General fabrication, repair work, workshops |

Introduction to Welding Technologies

Laser welding utilizes a highly concentrated laser beam to join materials with precision and minimal thermal distortion, making it ideal for high-speed, complex applications. Semi-automatic welding combines manual control with mechanized equipment, offering versatility and ease of use for various materials and thicknesses. Both technologies serve critical roles in manufacturing, with laser welding excelling in automation and precision, while semi-automatic welding provides flexibility and cost-effectiveness.

Overview of Laser Welding

Laser welding is a high-precision process that uses a concentrated laser beam to melt and join metals with minimal heat distortion and high welding speed. It offers deep weld penetration and is suitable for complex or delicate components, providing superior accuracy compared to semi-automatic welding methods. This technique reduces material waste and post-processing, making it ideal for industries demanding strong, clean welds like aerospace, automotive, and electronics manufacturing.

Overview of Semi-Automatic Welding

Semi-automatic welding combines manual operation with mechanized processes, allowing welders to control the welding torch while feed mechanisms supply the electrode or filler material automatically. This method offers greater precision and flexibility compared to fully manual welding, making it ideal for medium production volumes and complex welds. Semi-automatic welding techniques, such as MIG and TIG welding, provide enhanced control over weld quality and are widely used in automotive, shipbuilding, and fabrication industries.

Precision and Accuracy Comparison

Laser welding offers superior precision and accuracy compared to semi-automatic welding due to its highly focused energy beam that enables minimal heat distortion and narrow weld seams. Semi-automatic welding methods often result in greater variability influenced by operator skill and less controlled heat input, reducing consistency in weld quality. Advanced laser welding systems can achieve tolerances within micrometers, making them ideal for applications requiring fine detail and exact joint dimensions.

Speed and Efficiency Analysis

Laser welding achieves higher speed and precision compared to semi-automatic welding due to its focused heat source and minimal thermal distortion, making it ideal for high-volume production. Semi-automatic welding offers flexibility and ease of use but generally operates at slower speeds and requires more manual intervention, reducing overall efficiency. The advanced automation in laser welding significantly enhances throughput and consistency, optimizing manufacturing cycles in industries like automotive and aerospace.

Material Compatibility

Laser welding offers superior precision and is highly compatible with a wide range of materials, including stainless steel, aluminum, and titanium, due to its concentrated heat source and minimal thermal distortion. Semi-automatic welding works well with common metals like carbon steel and mild steel but may struggle with thin or dissimilar materials due to less control over heat input. Material compatibility in laser welding extends to complex alloys and thin sheets, making it preferable for advanced manufacturing requiring high-quality joints.

Cost Implications

Laser welding typically involves higher initial investment costs due to expensive equipment and specialized training requirements, but it offers superior precision, faster processing speeds, and lower labor costs over time. Semi-automatic welding has lower upfront expenses and equipment costs, making it more accessible for small-scale or less complex projects, though it demands higher labor input and longer welding times, increasing operational costs. Evaluating cost implications depends on production volume, complexity, and desired quality, where laser welding becomes cost-effective for high-volume or intricate assemblies, while semi-automatic welding suits lower-volume or simpler applications.

Safety Considerations

Laser welding offers enhanced safety through precise, focused beams that reduce exposure to harmful fumes and minimize heat-affected zones, lowering the risk of burns and fire hazards. Semi-automatic welding requires more operator intervention, increasing exposure to ultraviolet radiation, sparks, and molten metal splatter, which raises the potential for injuries and the necessity for robust protective gear. Implementing proper ventilation, protective equipment, and automated controls are critical safety measures in both welding methods to mitigate occupational hazards.

Industry Applications

Laser welding offers precise, high-speed joining ideal for aerospace, automotive, and electronics industries requiring minimal heat distortion and strong, clean welds. Semi-automatic welding remains popular in construction, shipbuilding, and heavy equipment sectors where versatility and ease of use accommodate diverse metal thicknesses and complex assembly tasks. Both technologies optimize production efficiency but diverge in suitability based on precision demands and material types.

Choosing the Right Welding Method

Laser welding offers high precision and speed, ideal for thin materials and intricate designs, while semi-automatic welding provides greater flexibility for thicker metals and varied joint types. Selecting the right welding method depends on project requirements such as weld quality, production volume, material thickness, and cost efficiency. Assessing factors like automation level, joint accessibility, and desired mechanical properties ensures optimal performance and resource allocation.

Laser welding Infographic

libterm.com

libterm.com