Modbus and CANopen are widely used industrial communication protocols enabling seamless data exchange between devices in automation systems. Modbus operates primarily over serial lines and Ethernet, offering simplicity and broad compatibility, while CANopen is designed for real-time control in embedded systems using the Controller Area Network (CAN) bus. Explore the differences and applications of these protocols to optimize your industrial communication network.

Table of Comparison

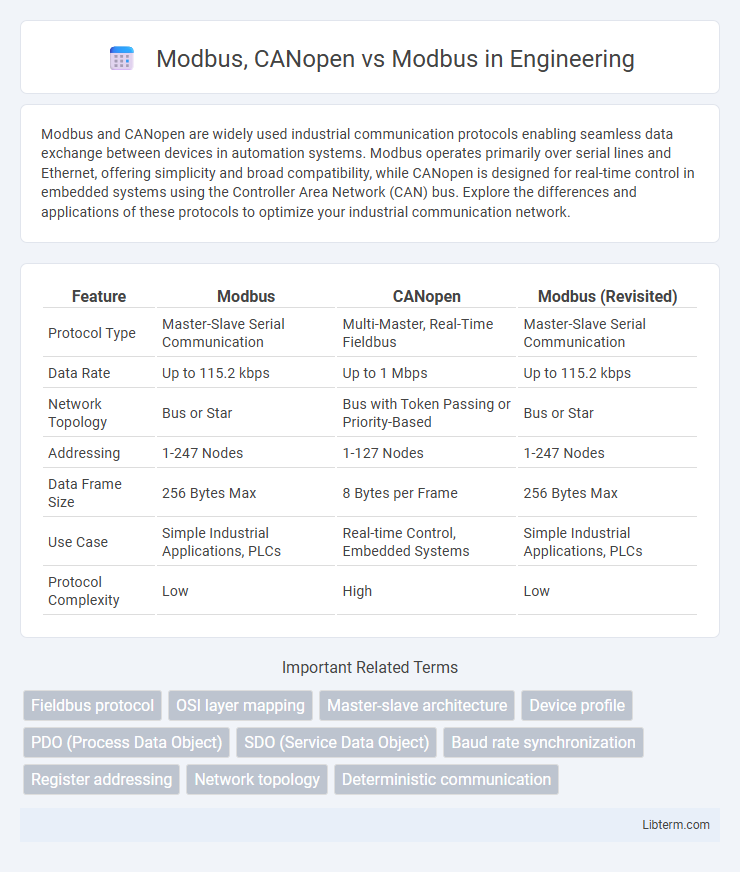

| Feature | Modbus | CANopen | Modbus (Revisited) |

|---|---|---|---|

| Protocol Type | Master-Slave Serial Communication | Multi-Master, Real-Time Fieldbus | Master-Slave Serial Communication |

| Data Rate | Up to 115.2 kbps | Up to 1 Mbps | Up to 115.2 kbps |

| Network Topology | Bus or Star | Bus with Token Passing or Priority-Based | Bus or Star |

| Addressing | 1-247 Nodes | 1-127 Nodes | 1-247 Nodes |

| Data Frame Size | 256 Bytes Max | 8 Bytes per Frame | 256 Bytes Max |

| Use Case | Simple Industrial Applications, PLCs | Real-time Control, Embedded Systems | Simple Industrial Applications, PLCs |

| Protocol Complexity | Low | High | Low |

Introduction to Modbus and CANopen

Modbus is a widely used communication protocol primarily designed for industrial automation systems, enabling devices like PLCs, sensors, and HMIs to exchange data over serial lines or Ethernet. CANopen is a higher-layer protocol based on the CAN (Controller Area Network) bus, optimized for embedded control systems in automotive and industrial applications, featuring standardized device profiles and real-time data communication. Both protocols facilitate device interoperability but differ in architecture, with Modbus emphasizing simplicity in master-slave communication and CANopen enabling more complex network management and distributed control.

Overview of Modbus Protocol

Modbus is a serial communication protocol widely used for connecting industrial electronic devices, characterized by its simplicity and ease of implementation in automation systems. Unlike CANopen, which is a higher-layer protocol built on CAN (Controller Area Network) focusing on distributed control in real-time systems, Modbus operates primarily over serial lines such as RS-232 or RS-485, supporting master-slave communication. Modbus's structured frame format and open protocol standard make it highly adaptable for device interoperability in industrial environments such as SCADA and PLC networks.

Overview of CANopen Protocol

CANopen protocol is a standardized communication protocol based on the CAN (Controller Area Network) specification, primarily designed for embedded systems in automation, automotive, and industrial applications. It defines device profiles, communication objects, and network management to enable real-time data exchange and interoperability between devices such as sensors, actuators, and controllers. Compared to Modbus, CANopen offers higher efficiency and robustness in distributed control systems with features like dynamic node addressing, error detection, and flexible communication services.

Key Features of Modbus

Modbus is a widely adopted communication protocol in industrial automation known for its simplicity, ease of implementation, and support for both serial and TCP/IP networks. Key features of Modbus include its master-slave architecture, standardized function codes for reading and writing data, and compatibility with a wide range of devices, making it ideal for monitoring and control systems. Unlike CANopen, which provides a more complex and feature-rich protocol with built-in device profiles and real-time capabilities, Modbus prioritizes straightforward communication and interoperability across diverse industrial equipment.

Key Features of CANopen

CANopen excels in real-time communication, device profile standardization, and network management, making it ideal for complex automation systems. It supports distributed control with built-in error handling, dynamic node configuration, and flexible data exchange mechanisms such as PDO (Process Data Objects) and SDO (Service Data Objects). Compared to Modbus, CANopen offers enhanced interoperability, faster data transmission, and robust synchronization suitable for high-performance industrial environments.

Modbus vs CANopen: Communication Methods

Modbus operates primarily using a master-slave communication method over serial or TCP/IP networks, facilitating straightforward, deterministic data exchange ideal for simple control systems. CANopen employs a multi-master, event-driven communication strategy on a CAN bus, supporting real-time, synchronized data transfer with advanced error handling and network management. The choice between Modbus and CANopen depends on system complexity, real-time requirements, and network topology, with Modbus favoring simplicity and compatibility, while CANopen excels in robustness and scalability.

Data Handling and Scalability Comparison

Modbus utilizes a master-slave communication model with simple data handling, ideal for smaller networks but limited scalability due to its polling mechanism. CANopen offers more advanced data handling with object-oriented communication and supports dynamic node addressing, providing superior scalability for complex, distributed systems. While Modbus focuses on straightforward register-based data exchange, CANopen's standardized device profiles and flexible messaging enable efficient management of large networks and diverse device types.

Industrial Applications: Modbus vs CANopen

Modbus is widely used in industrial automation for its simplicity and compatibility with various PLCs and SCADA systems, facilitating easy integration and data exchange over serial and Ethernet networks. CANopen enhances industrial applications by offering robust real-time communication, fault confinement, and standardized device profiles, making it ideal for complex automation systems requiring high reliability and faster data transfer. Modbus suits straightforward control tasks and legacy equipment, while CANopen excels in modular machinery, robotics, and motion control demanding deterministic performance and extensive diagnostics.

Advantages and Limitations of Each Protocol

Modbus offers simplicity and wide industry support, making it ideal for basic communication in industrial automation, but it lacks advanced data structuring and error handling found in CANopen. CANopen provides robust error detection, real-time capabilities, and flexible network management suitable for complex systems, yet it requires more configuration and higher implementation complexity. While Modbus excels in ease of use and legacy device integration, CANopen outperforms in scalability and reliability for modern, safety-critical applications.

Choosing the Right Protocol: Factors to Consider

Choosing the right protocol between Modbus and CANopen depends on factors like network size, communication speed, and system complexity. Modbus excels in simple, low-speed networks with easy integration, while CANopen supports higher speed, real-time control, and robust error handling suited for complex automation and industrial applications. Consider device compatibility, scalability requirements, and latency tolerance when selecting the optimal communication protocol for your project.

Modbus, CANopen Infographic

libterm.com

libterm.com