A control system regulates the behavior of other devices or systems using control loops to maintain desired outputs in dynamic environments. It plays a crucial role in automation, enhancing efficiency, accuracy, and safety across various industries such as manufacturing, robotics, and aerospace. Discover how your understanding of control systems can unlock new possibilities by reading the rest of this article.

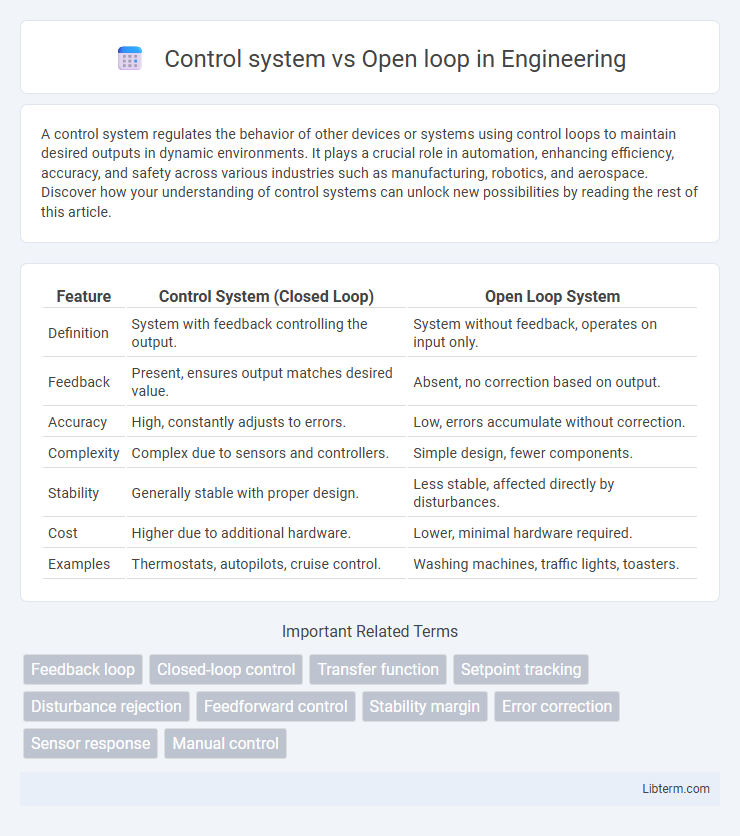

Table of Comparison

| Feature | Control System (Closed Loop) | Open Loop System |

|---|---|---|

| Definition | System with feedback controlling the output. | System without feedback, operates on input only. |

| Feedback | Present, ensures output matches desired value. | Absent, no correction based on output. |

| Accuracy | High, constantly adjusts to errors. | Low, errors accumulate without correction. |

| Complexity | Complex due to sensors and controllers. | Simple design, fewer components. |

| Stability | Generally stable with proper design. | Less stable, affected directly by disturbances. |

| Cost | Higher due to additional hardware. | Lower, minimal hardware required. |

| Examples | Thermostats, autopilots, cruise control. | Washing machines, traffic lights, toasters. |

Introduction to Control Systems

Control systems regulate the behavior of devices or processes using feedback to achieve desired outputs, distinguishing them clearly from open loop systems that operate without feedback. Open loop control systems execute predetermined commands without adjusting based on output, often resulting in less accuracy and adaptability. Understanding the difference between closed loop control systems and open loop systems is fundamental for designing efficient automated processes and enhancing system stability.

Understanding Open Loop Control Systems

Open loop control systems operate by sending a fixed input to the system without feedback, resulting in no automatic correction for disturbances or variations. These systems rely heavily on precise calibration and predictable environments to maintain desired output levels. Understanding open loop control is essential for applications where feedback is unnecessary or impractical, such as simple motor controls or timed irrigation systems.

Key Components of Open Loop Systems

Open loop control systems consist primarily of key components such as the input or controller, the actuator, the process or plant, and the output. These systems function without feedback, relying solely on the initial input to drive the actuator and control the process, with no sensors or mechanisms to correct errors or disturbances. The absence of a feedback loop differentiates open loop systems from closed loop control, making them simpler but less accurate under varying conditions.

Closed Loop Control System Overview

Closed loop control systems continuously monitor output signals through feedback to adjust inputs, ensuring precise and stable system behavior. Unlike open loop systems, which operate without feedback, closed loop systems reduce errors caused by disturbances and model inaccuracies. Key components include sensors, controllers, and actuators working together to maintain desired performance in dynamic environments.

Comparative Analysis: Open Loop vs Closed Loop

Open loop control systems operate without feedback, making them simpler and less expensive but prone to inaccuracies due to external disturbances and system variations. Closed loop control systems utilize feedback to continuously adjust the output, enhancing accuracy, stability, and adaptability in dynamic environments. Comparative analysis reveals closed loop systems outperform open loop counterparts in precision and robustness, especially in applications requiring real-time corrections and error minimization.

Advantages and Disadvantages of Open Loop Systems

Open loop control systems offer simplicity, cost-effectiveness, and ease of implementation since they do not require feedback mechanisms, making them suitable for applications with predictable and constant inputs. However, their main disadvantage lies in the inability to correct errors or adapt to disturbances, leading to reduced accuracy and reliability in dynamic or uncertain environments. This lack of feedback results in limited precision compared to closed loop control systems, especially in processes requiring real-time adjustments.

Performance Criteria in Control Systems

Control systems are evaluated based on performance criteria such as stability, accuracy, and response time, where closed-loop systems excel by continuously adjusting inputs using feedback to minimize errors. Open-loop control systems lack feedback mechanisms, resulting in consistent performance but limited adaptability to disturbances or parameter variations. The inherent feedback in closed-loop systems enhances dynamic performance and robustness, making them preferable in applications requiring precise control.

Application Areas: Open Loop vs Closed Loop

Open loop control systems find applications in simple, low-cost devices such as household appliances and basic irrigation systems where feedback is unnecessary. Closed loop control systems dominate complex, precision-critical applications like industrial automation, robotics, and aerospace, providing real-time error correction through continuous feedback. Industries demanding high accuracy and adaptive response rely heavily on closed loop systems for optimal performance and stability.

Challenges in Implementing Open Loop Controls

Open loop control systems face significant challenges due to their inability to adjust to disturbances or changes in system dynamics, resulting in reduced accuracy and reliability. Without feedback mechanisms, these systems cannot correct errors, making them unsuitable for processes requiring precision or varying operating conditions. Implementing open loop controls often requires highly predictable environments, limiting their effectiveness in complex or fluctuating applications.

Future Trends in Control System Technologies

Future trends in control system technologies emphasize the integration of artificial intelligence and machine learning to enhance adaptive and predictive capabilities beyond traditional open loop systems. Advancements in IoT and edge computing enable real-time data processing and decentralized control, improving system responsiveness and reliability. These innovations are driving a shift from simple open loop architectures toward intelligent, self-optimizing control frameworks for complex industrial and autonomous applications.

Control system Infographic

libterm.com

libterm.com