Mechanical filters offer precise frequency selection by utilizing resonators to process electrical signals, making them essential in communication and signal processing devices. Their ability to provide sharp bandwidth control and high selectivity improves performance in radios, transmitters, and receivers. Discover how mechanical filters can enhance your electronic systems by reading the rest of the article.

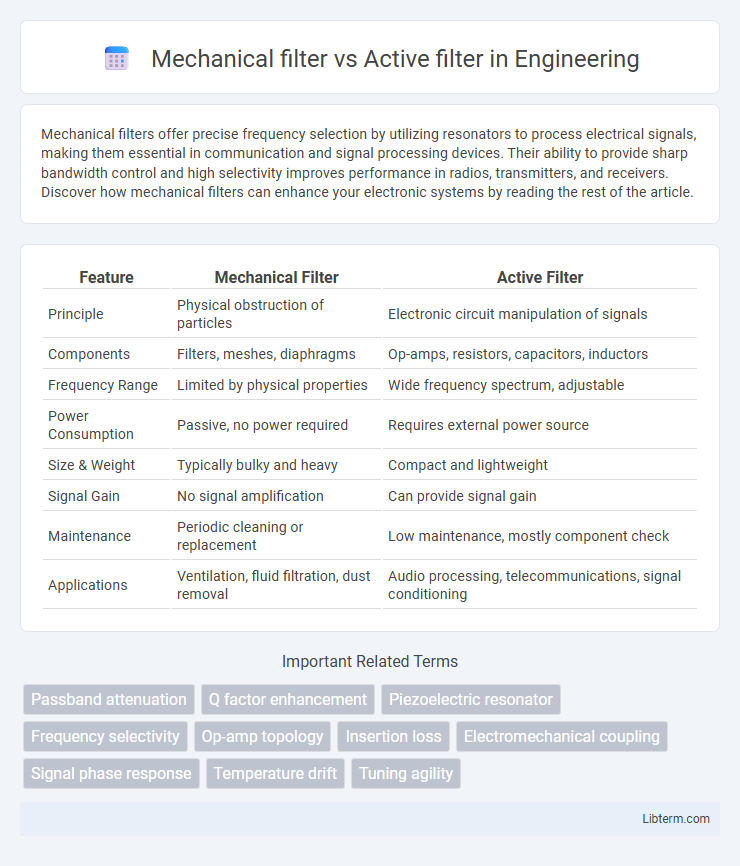

Table of Comparison

| Feature | Mechanical Filter | Active Filter |

|---|---|---|

| Principle | Physical obstruction of particles | Electronic circuit manipulation of signals |

| Components | Filters, meshes, diaphragms | Op-amps, resistors, capacitors, inductors |

| Frequency Range | Limited by physical properties | Wide frequency spectrum, adjustable |

| Power Consumption | Passive, no power required | Requires external power source |

| Size & Weight | Typically bulky and heavy | Compact and lightweight |

| Signal Gain | No signal amplification | Can provide signal gain |

| Maintenance | Periodic cleaning or replacement | Low maintenance, mostly component check |

| Applications | Ventilation, fluid filtration, dust removal | Audio processing, telecommunications, signal conditioning |

Introduction to Mechanical and Active Filters

Mechanical filters utilize physical components such as resonators and diaphragms to selectively transmit or block specific frequency ranges, often found in radio frequency and audio applications. Active filters employ operational amplifiers, resistors, and capacitors to achieve precise signal filtering with the advantage of gain and tunable frequency response. The fundamental difference lies in mechanical filters relying on physical vibrations and structures, while active filters depend on electronic circuitry for signal processing.

Basic Principles of Mechanical Filters

Mechanical filters operate based on the principles of resonance and vibration within physical structures, such as quartz crystals or tuning forks, to selectively pass or reject frequencies. They rely on mechanical motion and energy transfer through elastic elements to achieve filtering, providing high stability and low noise. Unlike active filters that depend on electronic components like operational amplifiers and transistors, mechanical filters use passive mechanical elements to perform signal filtering.

Core Operation of Active Filters

Active filters utilize electronic components such as operational amplifiers, resistors, and capacitors to amplify and shape frequency signals, enabling precise control over the filter's response characteristics. Unlike mechanical filters that rely on physical resonators and mechanical vibrations, active filters offer greater flexibility, adjustable cutoff frequencies, and improved signal gain without the need for inductors. The core operation of active filters centers on voltage amplification and feedback mechanisms to achieve desired bandpass, low-pass, high-pass, or band-stop filtering effects with enhanced accuracy and efficiency.

Key Differences Between Mechanical and Active Filters

Mechanical filters rely on physical components like resonators or membranes to separate signals, offering high selectivity and low distortion in audio or RF systems. Active filters use operational amplifiers, resistors, and capacitors to control frequency response, providing adjustable gain and flexibility in circuit design. Mechanical filters typically excel in stability and durability for fixed-frequency applications, while active filters are preferred for tunability and integration in low-voltage electronics.

Advantages of Mechanical Filters

Mechanical filters offer superior selectivity and high Q factor, making them ideal for applications requiring precise frequency discrimination. Their inherent passive design results in low noise and excellent linearity without the need for external power sources. Robustness against electromagnetic interference and simple construction further enhance their reliability and longevity in harsh environments.

Advantages of Active Filters

Active filters offer precise control over frequency response, enabling customizable amplification and filtering characteristics that mechanical filters cannot achieve. These filters utilize operational amplifiers and active components, which provide gain and improved signal integrity without passive component bulk. Unlike mechanical filters, active filters are more compact, consume less power, and can be easily integrated into modern electronic circuits for flexible signal processing.

Typical Applications for Mechanical Filters

Mechanical filters are commonly utilized in radio frequency (RF) and intermediate frequency (IF) stages of communication receivers due to their high selectivity and stability. They excel in applications requiring fixed, narrowband filtering such as amateur radio, broadcast receivers, and HF/VHF transceivers. These filters offer superior performance in harsh environments and are preferred when low power consumption and minimal signal distortion are critical.

Common Uses for Active Filters

Active filters are widely used in audio processing devices, communication systems, and biomedical instruments due to their ability to amplify signals and provide precise frequency selection with low distortion. Unlike mechanical filters, active filters can be easily tuned and integrated into electronic circuits for tasks such as noise reduction, signal shaping, and frequency response adjustment. Their common applications include equalizers, radio receivers, and ECG machines where stable and reliable filtering performance is essential.

Performance Comparison: Mechanical vs Active Filters

Mechanical filters offer high selectivity and excellent linear phase response, making them ideal for applications requiring precise frequency isolation, such as radio communications. Active filters provide greater flexibility with adjustable gain, wider bandwidth, and the ability to operate at low frequencies using operational amplifiers, enabling precise control over filter characteristics. In terms of performance, mechanical filters excel in stability and low insertion loss, while active filters outperform in adaptability and integration within electronic circuits.

Choosing the Right Filter for Your Application

Mechanical filters offer high reliability and durability for vibration and noise attenuation in harsh environments, making them ideal for industrial machinery and automotive applications. Active filters provide greater precision and flexibility by electronically adjusting filter parameters to cater to varying signal frequencies, commonly used in audio processing and telecommunications. Selecting the right filter requires evaluating the application's frequency range, signal integrity requirements, environmental conditions, and cost constraints to determine whether passive mechanical robustness or dynamic electronic control is more suitable.

Mechanical filter Infographic

libterm.com

libterm.com