Steel reinforcement enhances concrete structures by providing tensile strength and improving durability under stress. It prevents cracking and structural failure, ensuring longevity in buildings, bridges, and other infrastructure. Discover how incorporating steel reinforcement can elevate the performance and safety of your construction projects in the rest of this article.

Table of Comparison

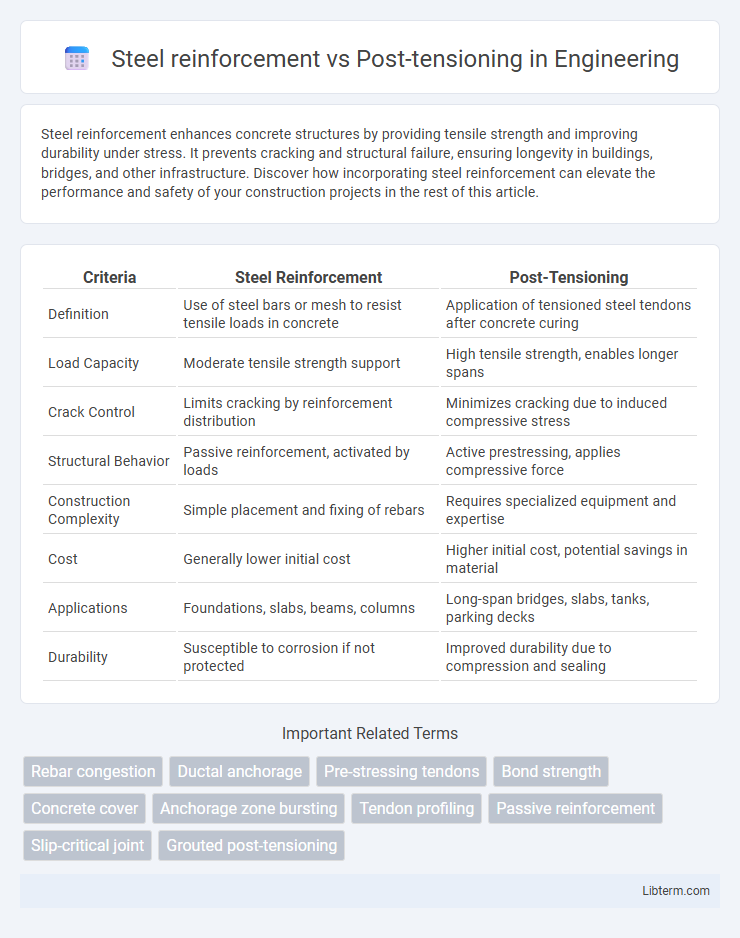

| Criteria | Steel Reinforcement | Post-Tensioning |

|---|---|---|

| Definition | Use of steel bars or mesh to resist tensile loads in concrete | Application of tensioned steel tendons after concrete curing |

| Load Capacity | Moderate tensile strength support | High tensile strength, enables longer spans |

| Crack Control | Limits cracking by reinforcement distribution | Minimizes cracking due to induced compressive stress |

| Structural Behavior | Passive reinforcement, activated by loads | Active prestressing, applies compressive force |

| Construction Complexity | Simple placement and fixing of rebars | Requires specialized equipment and expertise |

| Cost | Generally lower initial cost | Higher initial cost, potential savings in material |

| Applications | Foundations, slabs, beams, columns | Long-span bridges, slabs, tanks, parking decks |

| Durability | Susceptible to corrosion if not protected | Improved durability due to compression and sealing |

Introduction to Structural Reinforcement Methods

Steel reinforcement involves embedding steel bars or mesh within concrete to enhance tensile strength, commonly used in reinforced concrete structures. Post-tensioning applies tension to high-strength steel tendons after concrete curing, enabling longer spans and thinner slabs by compressing the concrete. Both methods improve load-bearing capacity and structural performance but differ in application, stress control, and flexibility in design.

Understanding Traditional Steel Reinforcement

Traditional steel reinforcement involves embedding steel bars or meshes within concrete to improve tensile strength and control cracking. This method relies on the steel's high ductility and bond with concrete to distribute loads effectively, making it suitable for various structural applications. While versatile and widely used, traditional reinforcement can lead to increased concrete volume and potential corrosion issues compared to post-tensioning systems.

Fundamentals of Post-tensioning Technology

Post-tensioning technology involves the application of high-strength steel tendons tensioned after concrete placement, creating compressive forces that enhance structural performance and reduce cracking compared to traditional steel reinforcement. Unlike conventional steel reinforcement, which relies on embedded rebar to resist tensile stresses, post-tensioning actively induces prestress, allowing for longer spans, thinner slabs, and improved load distribution. This method optimizes material usage and extends the durability of concrete structures by minimizing tensile stresses and controlling deflections effectively.

Material Composition and Properties

Steel reinforcement consists primarily of carbon steel bars or mesh with high tensile strength and ductility, enabling them to resist cracking and withstand tensile stresses in concrete structures. Post-tensioning uses high-strength steel tendons or cables, typically made from strands of cold-drawn steel wire, characterized by superior tensile capacity and elasticity, allowing controlled compression in concrete after curing. The key difference lies in carbon steel's conventional reinforcement role versus post-tensioning's use of prestressed steel to enhance load-bearing performance and minimize concrete deflection.

Installation Techniques Compared

Steel reinforcement typically involves placing pre-cut steel bars or meshes within concrete forms, secured with ties and spacers before concrete pouring, ensuring uniform coverage and stress distribution. Post-tensioning requires installing high-strength steel tendons within ducts, which are later tensioned using hydraulic jacks after concrete has reached its initial strength, allowing active load counteraction. Compared to conventional steel reinforcement, post-tensioning demands specialized equipment and skilled labor for tensioning operations, resulting in thinner slabs and longer spans with reduced cracking.

Load-Bearing Capacity and Performance

Steel reinforcement provides high tensile strength by embedding steel bars within concrete, enhancing load-bearing capacity primarily through resistance to tension and cracking. Post-tensioning introduces controlled compression to concrete by tensioning steel tendons after curing, significantly increasing structural performance and allowing for longer spans with reduced material usage. Post-tensioned systems offer superior load distribution, minimized deflections, and enhanced durability compared to conventional steel-reinforced concrete.

Cost Implications and Economic Analysis

Steel reinforcement involves higher initial material costs due to the extensive use of steel bars, but generally requires less specialized labor and equipment, leading to moderate overall expenses in conventional construction. Post-tensioning significantly reduces steel quantity and concrete thickness, offering substantial material savings and enhanced structural performance, although it demands specialized labor, equipment, and rigorous quality control, increasing upfront costs. Economic analysis indicates post-tensioned systems provide long-term cost benefits through reduced maintenance, lower concrete volume, and improved load efficiency, making them economically advantageous in large-scale or complex projects despite higher initial investment.

Durability and Long-term Maintenance

Steel reinforcement offers proven durability with straightforward inspection and routine maintenance, ensuring structural integrity over time in various environmental conditions. Post-tensioning enhances durability by minimizing concrete cracking and reducing corrosion risks, leading to lower long-term maintenance costs and extended service life. Both methods require proper design and quality control to maximize lifespan and performance in construction applications.

Applications in Construction Projects

Steel reinforcement is widely used in construction projects for enhancing the tensile strength of concrete structures, making it ideal for slabs, beams, columns, and foundations in residential and commercial buildings. Post-tensioning is favored in large-scale infrastructure such as long-span bridges, parking garages, and high-rise buildings, where it reduces concrete cracking and allows for thinner slabs and longer spans. Both methods improve structural integrity, but post-tensioning offers greater flexibility and durability in complex engineering designs requiring high performance and reduced maintenance.

Steel Reinforcement vs Post-tensioning: Pros & Cons

Steel reinforcement offers high tensile strength and ease of construction, making it ideal for conventional concrete structures with predictable loads. Post-tensioning provides enhanced structural performance with reduced material usage and improved crack control but involves higher upfront costs and specialized labor. Choosing between steel reinforcement and post-tensioning depends on factors like project complexity, budget, span requirements, and long-term durability needs.

Steel reinforcement Infographic

libterm.com

libterm.com