Milling is a precise machining process that removes material from a workpiece using rotary cutters to shape and finish parts with accuracy and efficiency. It is essential in manufacturing industries for creating complex components in metal, plastic, and other materials. Discover how milling can enhance your production quality and explore key techniques in the full article.

Table of Comparison

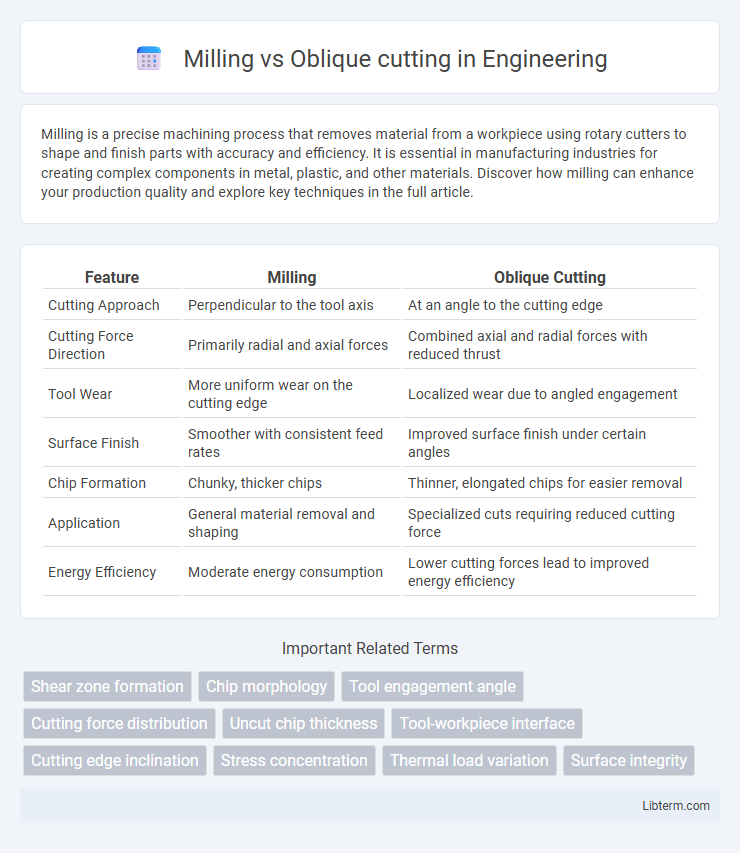

| Feature | Milling | Oblique Cutting |

|---|---|---|

| Cutting Approach | Perpendicular to the tool axis | At an angle to the cutting edge |

| Cutting Force Direction | Primarily radial and axial forces | Combined axial and radial forces with reduced thrust |

| Tool Wear | More uniform wear on the cutting edge | Localized wear due to angled engagement |

| Surface Finish | Smoother with consistent feed rates | Improved surface finish under certain angles |

| Chip Formation | Chunky, thicker chips | Thinner, elongated chips for easier removal |

| Application | General material removal and shaping | Specialized cuts requiring reduced cutting force |

| Energy Efficiency | Moderate energy consumption | Lower cutting forces lead to improved energy efficiency |

Introduction to Milling and Oblique Cutting

Milling involves the rotary cutting of a workpiece using multi-toothed cutters to remove material and shape surfaces with high precision. Oblique cutting is characterized by the cutting edge being inclined at an angle to the direction of the workpiece feed, resulting in a helical shear deformation that enhances surface finish and chip flow. Understanding the differences in tool geometry and cutting mechanics between milling and oblique cutting is essential for optimizing machining processes and improving tool life.

Fundamentals of Milling Processes

Milling involves rotating multi-point cutting tools to remove material from a workpiece, enabling complex shapes and high precision. Oblique cutting occurs when the cutting edge is inclined relative to the direction of workpiece motion, producing a shearing action that reduces cutting forces and improves surface finish. Understanding chip formation, tool geometry, and cutting mechanics is fundamental to optimizing milling process efficiency and tool life.

Overview of Oblique Cutting Techniques

Oblique cutting techniques involve tool edges engaging the workpiece at an angle, which reduces cutting forces and improves surface finish compared to conventional milling. This method enhances chip flow and heat dissipation, leading to extended tool life and better dimensional accuracy in machining operations. It is widely used in applications requiring high precision and efficient material removal, such as aerospace and automotive component manufacturing.

Key Differences Between Milling and Oblique Cutting

Milling involves a rotating cutter removing material along multiple axes, enabling the creation of complex shapes and profiles, while oblique cutting uses a single-point cutting tool with the cutting edge set at an angle to the workpiece. The primary difference lies in tool geometry and motion: milling uses multi-tooth cutters rotating perpendicular or at an angle to the surface, whereas oblique cutting employs an angled approach to reduce cutting forces and improve surface finish. Milling typically processes larger workpieces with various materials, whereas oblique cutting is suited for more precise, controlled operations on smaller sections.

Tool Geometry Comparison: Milling vs Oblique Cutting

Milling tools typically feature multiple cutting edges arranged on a rotating cylindrical body, optimized for transverse cutting and high material removal rates. In contrast, oblique cutting tools possess a single cutting edge with a specific helix angle, allowing the cutting force to be distributed over a longer tool-chip interface, reducing cutting forces and improving surface finish. The geometry differences impact chip flow, cutting force direction, and tool wear, with milling favoring versatility and oblique cutting enhancing energy efficiency and tool life.

Chip Formation Dynamics

Milling produces segmented, discontinuous chips due to intermittent cutting, which enhances heat dissipation and reduces tool wear, while oblique cutting generates continuous or semi-continuous chips with shear forces acting at an angle, leading to smoother chip flow and improved surface finish. The chip formation dynamics in milling involve cyclic stresses that promote chip breakage, contrasting with the steady-state shear zone in oblique cutting that allows consistent chip thickness reduction. Understanding these differences is crucial for optimizing cutting parameters, tool geometry, and coolant application to maximize machining efficiency and tool life.

Surface Finish and Quality Outcomes

Milling typically produces a smoother surface finish due to its continuous cutting action and consistent chip formation, resulting in higher dimensional accuracy and reduced tool marks. Oblique cutting, characterized by an angled cutting edge, can cause variable surface roughness and may introduce residual stresses that affect overall quality outcomes. Optimizing cutting parameters in milling enhances surface integrity, while oblique cutting demands precise control to minimize surface defects and maintain finish quality.

Applications in Modern Manufacturing

Milling is widely used in modern manufacturing for creating complex shapes, slots, and intricate parts through rotary cutters, primarily in metalworking, aerospace, and automotive industries. Oblique cutting, characterized by angled chip flow, is essential in processes like turning and shaping to improve surface finish and tool life, commonly applied in high-speed machining and precision component production. Both methods optimize material removal rates and dimensional accuracy, crucial for advanced manufacturing of turbine blades, engine components, and precision molds.

Advantages and Limitations of Each Method

Milling offers high precision and versatility, enabling complex shapes and smooth surface finishes, but it often requires more setup time and specialized equipment. Oblique cutting allows for efficient material removal with reduced cutting force and improved chip flow, making it suitable for heavy-duty operations, though it may produce less accurate surface textures compared to milling. Selecting between these methods depends on the specific application requirements, balancing speed, accuracy, and tool wear considerations.

Choosing the Right Cutting Process for Your Needs

Milling offers precise material removal with versatile shapes, ideal for high-volume production and complex geometries, while oblique cutting provides smoother surface finishes and reduced cutting forces, suitable for delicate or fine finishing tasks. Selecting the right cutting process depends on factors such as material type, desired surface quality, production volume, and tool accessibility. Understanding these variables ensures optimized efficiency, cost-effectiveness, and product quality in manufacturing operations.

Milling Infographic

libterm.com

libterm.com