Fatigue originates from prolonged physical or mental exertion, leading to a decline in energy levels and impaired performance. It can also stem from underlying medical conditions, poor sleep quality, or chronic stress, affecting your overall well-being. Explore the rest of the article to understand the causes and effective strategies to combat fatigue.

Table of Comparison

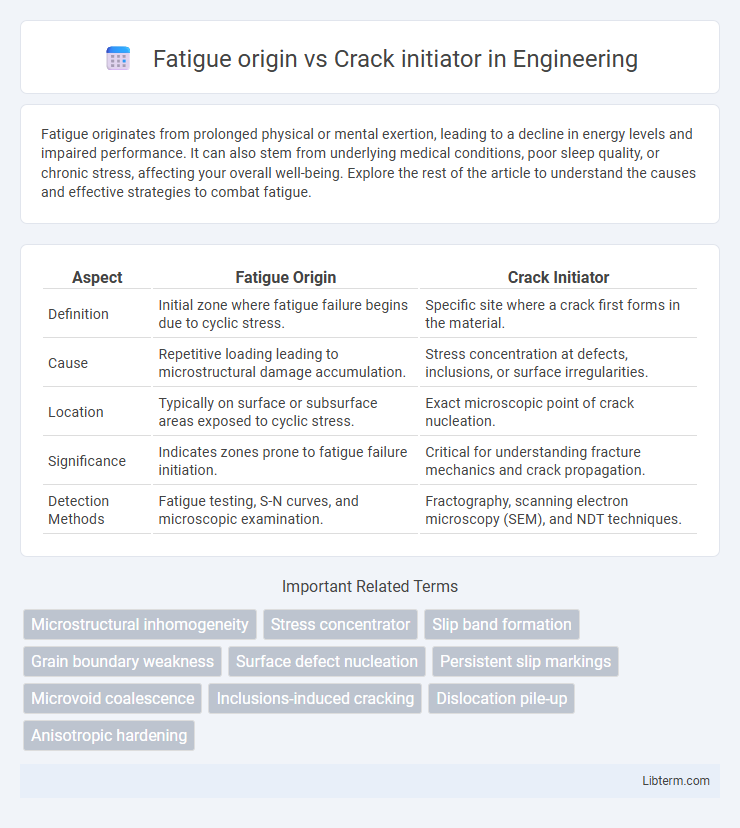

| Aspect | Fatigue Origin | Crack Initiator |

|---|---|---|

| Definition | Initial zone where fatigue failure begins due to cyclic stress. | Specific site where a crack first forms in the material. |

| Cause | Repetitive loading leading to microstructural damage accumulation. | Stress concentration at defects, inclusions, or surface irregularities. |

| Location | Typically on surface or subsurface areas exposed to cyclic stress. | Exact microscopic point of crack nucleation. |

| Significance | Indicates zones prone to fatigue failure initiation. | Critical for understanding fracture mechanics and crack propagation. |

| Detection Methods | Fatigue testing, S-N curves, and microscopic examination. | Fractography, scanning electron microscopy (SEM), and NDT techniques. |

Understanding Fatigue Origin and Crack Initiation

Fatigue origin refers to the specific site on a material or component where cyclic stress first causes microscopic damage, leading to crack initiation. Crack initiators often include surface defects, inclusions, or stress concentrators that serve as focal points for crack nucleation under repeated loading. Understanding the microstructural characteristics and stress distribution at the fatigue origin is crucial for predicting fatigue life and improving material resistance to crack initiation.

Distinguishing Fatigue Origins from Crack Initiators

Fatigue origins refer to the initial microscopic region where cyclic stress causes irreversible damage, whereas crack initiators are the specific sites where a macroscopic crack begins to propagate. Fatigue origins often involve microstructural features like inclusions or slip bands, while crack initiators correspond to the surface or subsurface points where stress concentration leads to crack growth. Distinguishing these two is essential in failure analysis to accurately identify the root cause of fatigue failure and improve material design.

Key Factors in Fatigue Crack Initiation

Fatigue crack initiation primarily originates from microstructural discontinuities such as inclusions, grain boundaries, and persistent slip bands that serve as stress concentrators. Key factors influencing fatigue crack initiation include cyclic stress amplitude, material microstructure, surface roughness, and environmental conditions like corrosion or temperature. Understanding the interplay between these factors helps predict fatigue life and improve materials engineering for enhanced durability.

Microstructural Influences on Fatigue Origins

Microstructural features such as grain boundaries, inclusions, and phase distributions significantly influence fatigue origin by acting as stress concentrators and interaction sites that accelerate crack initiation. Crack initiators often emerge from localized microstructural heterogeneities, including persistent slip bands and microvoids, which intensify cyclic stress and strain. Understanding the role of microstructural characteristics enables targeted material design to enhance fatigue resistance and delay crack initiation.

Surface Defects as Crack Initiators

Surface defects such as scratches, pits, and inclusions act as primary crack initiators in fatigue failure by concentrating stress and facilitating microcrack formation. These imperfections degrade the material's resistance to cyclic loading, promoting early crack nucleation at or near the surface. Understanding the size, shape, and distribution of surface defects is critical for predicting fatigue life and improving material design.

Stress Concentration and Fatigue Initiation

Stress concentration significantly influences fatigue initiation by creating localized regions with elevated stress levels that exceed the material's fatigue limit. Fatigue origin often coincides with these stress concentrators such as notches, sharp corners, or microstructural inhomogeneities, serving as crack initiators under cyclic loading conditions. Understanding the interplay between stress concentration factors and microstructural features is crucial for predicting fatigue life and preventing premature crack propagation.

Environmental Effects on Crack Initiation

Environmental effects significantly influence crack initiation during fatigue by accelerating microstructural degradation and promoting localized corrosion mechanisms. Factors such as humidity, temperature, and corrosive media alter the surface chemistry and stress distribution, enhancing crack nucleation sites and reducing fatigue life. Understanding these interactions between environmental conditions and material properties is crucial for predicting fatigue performance in service environments.

Inspection Methods for Identifying Fatigue Origins

Inspection methods for identifying fatigue origins primarily include non-destructive testing techniques such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods detect surface and subsurface discontinuities, corrosion pits, or inclusions that act as crack initiators. Advanced imaging techniques like scanning electron microscopy (SEM) provide detailed analysis of fracture surfaces to distinguish fatigue origins from crack initiation sites, enabling accurate failure assessment.

Common Materials and Their Crack Initiation Mechanisms

Fatigue origin and crack initiator are critical concepts in failure analysis of common materials such as steel, aluminum alloys, and titanium. In steels, crack initiation often occurs at microstructural inhomogeneities like inclusions or persistent slip bands, while aluminum alloys typically exhibit crack origin at surface scratches or corrosion pits; titanium alloys commonly initiate cracks at alpha/beta phase boundaries or grain orientations. Understanding these mechanisms allows engineers to improve material processing and surface treatments to delay crack initiation and extend fatigue life.

Prevention Strategies for Fatigue and Crack Initiation

Fatigue originates from cyclic stress leading to microscopic damage accumulation, whereas crack initiators are specific sites such as surface defects, inclusions, or corrosion pits where cracks form. Prevention strategies focus on material selection with high fatigue strength, surface treatments like shot peening to induce compressive residual stress, and avoiding stress concentrators through careful design and manufacturing processes. Regular inspections and controlled loading conditions further minimize the risk of fatigue crack initiation by detecting early damage and maintaining operational limits.

Fatigue origin Infographic

libterm.com

libterm.com