Compressed air is a versatile energy source used in various industries for powering tools, controlling automation systems, and cleaning processes. Efficient management of compressed air systems can significantly reduce energy consumption and operational costs in your facility. Discover practical tips and best practices for optimizing compressed air use throughout this article.

Table of Comparison

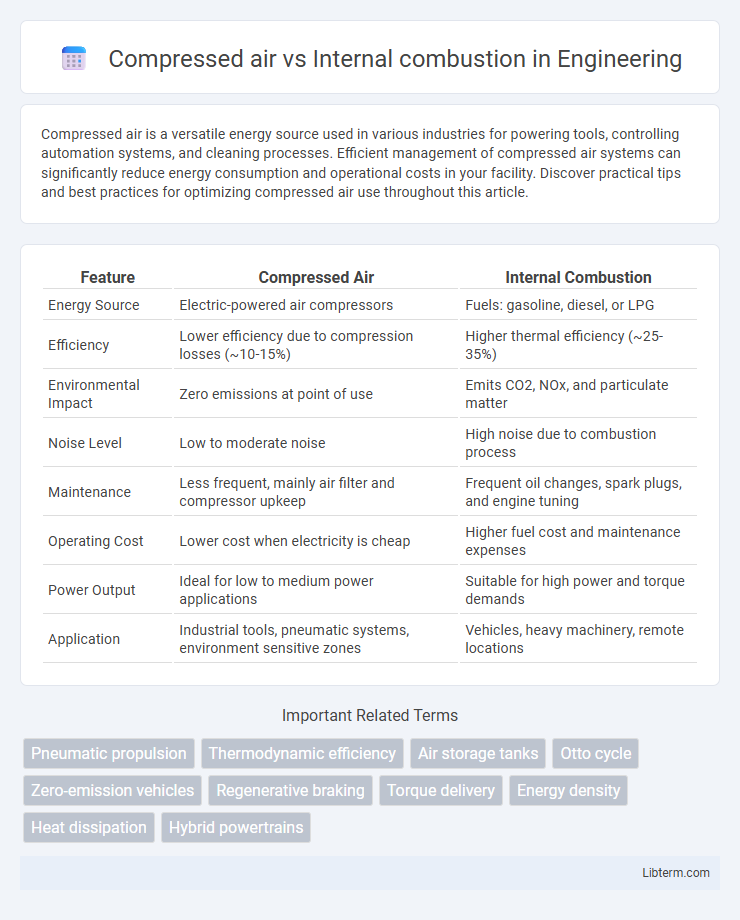

| Feature | Compressed Air | Internal Combustion |

|---|---|---|

| Energy Source | Electric-powered air compressors | Fuels: gasoline, diesel, or LPG |

| Efficiency | Lower efficiency due to compression losses (~10-15%) | Higher thermal efficiency (~25-35%) |

| Environmental Impact | Zero emissions at point of use | Emits CO2, NOx, and particulate matter |

| Noise Level | Low to moderate noise | High noise due to combustion process |

| Maintenance | Less frequent, mainly air filter and compressor upkeep | Frequent oil changes, spark plugs, and engine tuning |

| Operating Cost | Lower cost when electricity is cheap | Higher fuel cost and maintenance expenses |

| Power Output | Ideal for low to medium power applications | Suitable for high power and torque demands |

| Application | Industrial tools, pneumatic systems, environment sensitive zones | Vehicles, heavy machinery, remote locations |

Introduction: Compressed Air vs Internal Combustion

Compressed air engines operate by expanding stored pressurized air to generate mechanical power, offering zero-emission energy conversion compared to traditional internal combustion engines that rely on fuel combustion producing CO2 and pollutants. Internal combustion engines dominate automotive and industrial sectors due to high energy density and established infrastructure, while compressed air systems prioritize environmental sustainability and reduced lifecycle costs. Efficiency challenges and storage limitations remain critical factors differentiating compressed air technology from the widespread internal combustion engine applications.

Principle of Operation

Compressed air engines operate by releasing stored high-pressure air to drive pistons or turbines, converting potential energy into mechanical work without combustion. Internal combustion engines rely on the ignition of fuel-air mixtures within cylinders, generating expanding gases that push pistons and produce power. The fundamental difference lies in energy source, where compressed air uses mechanical compression and release, while internal combustion depends on chemical energy from fuel combustion.

Energy Efficiency Comparison

Compressed air engines convert stored air pressure into mechanical work with an energy efficiency typically between 10-25%, largely due to losses during air compression and expansion. Internal combustion engines (ICEs) achieve higher energy efficiency, generally around 25-30% for gasoline and up to 40% for diesel engines, by directly converting chemical energy from fuel combustion into mechanical power. The lower thermal efficiency and energy storage challenges limit compressed air engines compared to the more mature and efficient combustion processes in ICEs.

Environmental Impact and Emissions

Compressed air engines produce zero direct emissions, making them environmentally friendly compared to internal combustion engines that emit significant levels of CO2, NOx, and particulate matter. The environmental impact of compressed air vehicles depends primarily on the electricity source used to compress the air, with renewable energy sources resulting in near-zero lifecycle emissions. Internal combustion engines contribute to air pollution and climate change due to fossil fuel combustion, whereas compressed air technology offers a cleaner alternative with reduced greenhouse gas emissions and improved air quality.

Performance and Power Output

Compressed air engines deliver lower power output and limited torque compared to internal combustion engines, making them less suitable for high-performance applications. Internal combustion engines offer higher energy density and rapid fuel combustion, resulting in significantly greater horsepower and acceleration capabilities. Efficiency of internal combustion engines in converting fuel energy to mechanical power generally outperforms compressed air systems, which suffer from energy losses during air compression and expansion.

Maintenance and Reliability

Compressed air engines typically require less maintenance than internal combustion engines due to fewer moving parts and no need for lubrication or fuel systems. Internal combustion engines experience higher wear and tear from combustion heat and pressure, necessitating regular oil changes, filter replacements, and complex engine tuning. Reliability of compressed air systems is enhanced by lower risk of mechanical failure and simpler component design, whereas internal combustion engines depend on fuel quality and frequent maintenance schedules to ensure consistent performance.

Cost Analysis: Initial and Long-Term

Compressed air vehicles typically have lower initial costs due to simpler engine designs and fewer moving parts compared to internal combustion engines. Long-term expenses favor compressed air systems with reduced fuel costs, lower maintenance requirements, and fewer emissions-related issues, although energy storage efficiency and infrastructure can affect total cost of ownership. Internal combustion engines incur higher fuel costs and frequent maintenance, contributing to increased lifetime expenses despite widespread refueling infrastructure.

Common Applications and Use Cases

Compressed air systems are widely used in industrial automation, pneumatic tools, and HVAC controls, providing clean, efficient energy for applications requiring moderate power and precise control. Internal combustion engines dominate transportation, construction machinery, and agriculture due to their high power density and portability in fuel-based energy conversion. Both technologies enable specific use cases, with compressed air excelling in environments demanding low emissions and safety, while internal combustion suits high-power, mobile applications.

Safety Considerations

Compressed air systems offer higher safety levels due to their non-flammable and non-toxic nature, significantly reducing risks of explosions or hazardous emissions compared to internal combustion engines. Internal combustion engines involve combustion of fuel, posing fire hazards, toxic exhaust emissions, and potential carbon monoxide poisoning risks, necessitating stringent ventilation and safety protocols. Proper maintenance and safety measures are critical for both technologies to prevent mechanical failures, but compressed air systems inherently minimize fire and toxicity dangers.

Future Prospects and Technological Advancements

Compressed air technology is advancing with enhanced energy storage efficiency and lightweight tank designs, positioning it as a potential sustainable alternative to internal combustion engines (ICE) amid stricter emissions regulations. Innovations in high-pressure air compression, rapid refueling infrastructure, and hybrid systems integrating electric power are accelerating its feasibility in automotive and industrial applications. In contrast, ICE development increasingly focuses on fuel efficiency improvements and clean fuel adaptations, yet compressed air propulsion offers a zero-emission solution aligning with future environmental mandates and renewable energy integration.

Compressed air Infographic

libterm.com

libterm.com