Mass production revolutionizes manufacturing by producing large quantities of standardized products efficiently and at reduced costs. It leverages assembly lines, automation, and specialized machinery to maintain consistent quality while meeting high consumer demand. Discover how mastering mass production can enhance your business operations in the detailed insights ahead.

Table of Comparison

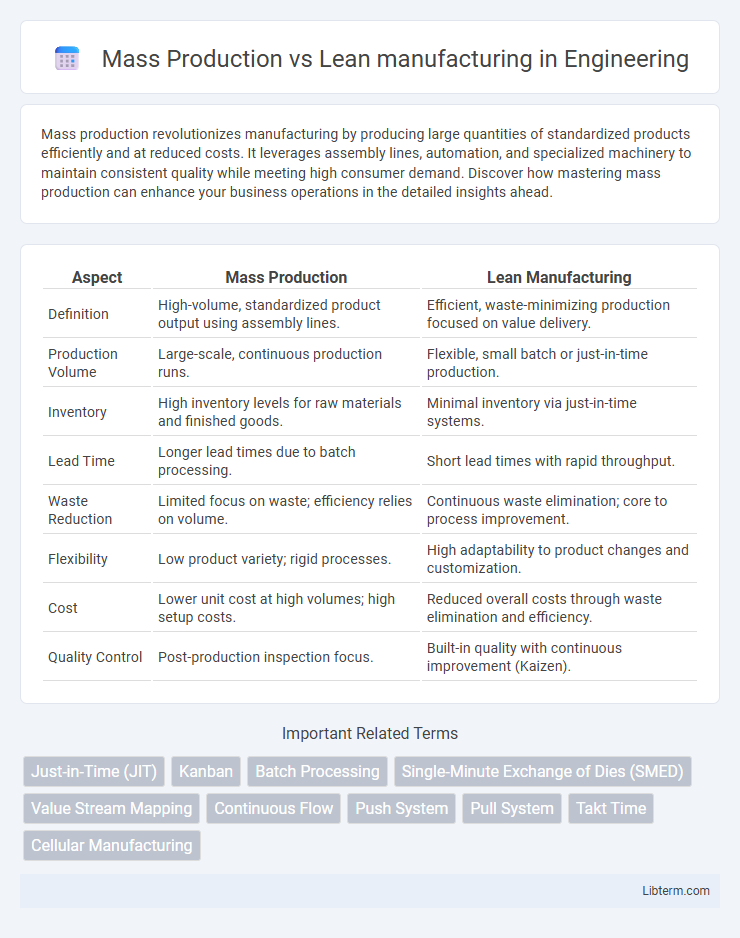

| Aspect | Mass Production | Lean Manufacturing |

|---|---|---|

| Definition | High-volume, standardized product output using assembly lines. | Efficient, waste-minimizing production focused on value delivery. |

| Production Volume | Large-scale, continuous production runs. | Flexible, small batch or just-in-time production. |

| Inventory | High inventory levels for raw materials and finished goods. | Minimal inventory via just-in-time systems. |

| Lead Time | Longer lead times due to batch processing. | Short lead times with rapid throughput. |

| Waste Reduction | Limited focus on waste; efficiency relies on volume. | Continuous waste elimination; core to process improvement. |

| Flexibility | Low product variety; rigid processes. | High adaptability to product changes and customization. |

| Cost | Lower unit cost at high volumes; high setup costs. | Reduced overall costs through waste elimination and efficiency. |

| Quality Control | Post-production inspection focus. | Built-in quality with continuous improvement (Kaizen). |

Introduction to Mass Production and Lean Manufacturing

Mass production emphasizes high-volume output through standardized processes, reducing costs by minimizing unit time and labor variability. Lean manufacturing targets waste elimination and continuous improvement, optimizing resources by focusing on value-added activities in production. Both methods address manufacturing efficiency but differ in approach: mass production prioritizes scale, while lean manufacturing prioritizes flexibility and quality.

Historical Context and Evolution

Mass production originated in the early 20th century, popularized by Henry Ford's assembly line that revolutionized automobile manufacturing by producing large quantities at low cost. Lean manufacturing evolved from the Toyota Production System in post-World War II Japan, focusing on eliminating waste, improving efficiency, and responding flexibly to customer demand. The transition from mass production to lean manufacturing reflects a shift from volume-driven, standardized output toward value-driven, continuous improvement processes.

Core Principles of Mass Production

Mass production relies on standardized processes, high volume output, and repetitive operations to maximize efficiency and reduce per-unit costs. The core principles emphasize strict division of labor, specialized machinery, and product uniformity to achieve consistent quality at scale. This method prioritizes economies of scale through continuous production runs and minimal product variation.

Fundamental Concepts of Lean Manufacturing

Lean manufacturing centers on eliminating waste, optimizing processes, and delivering maximum customer value by using techniques such as Just-In-Time production and continuous improvement (Kaizen). Unlike mass production, which emphasizes high volume and economies of scale, lean manufacturing prioritizes flexibility, quality, and efficiency through value stream mapping and pull systems. Fundamental concepts include reducing inventory, minimizing defects, and fostering a culture of employee involvement to streamline production flow and reduce lead times.

Efficiency and Productivity Comparison

Mass production emphasizes high output through standardized processes and economies of scale, maximizing efficiency by producing large volumes of uniform products. Lean manufacturing prioritizes minimizing waste and continuous improvement, enhancing productivity with flexible workflows tailored to customer demand and quality optimization. Efficiency in mass production hinges on repetitive tasks and machinery utilization, while lean manufacturing drives productivity by reducing cycle times and eliminating non-value-added activities.

Cost Implications and Resource Utilization

Mass production reduces unit costs through high-volume output and standardized processes, leading to significant economies of scale but often incurs higher upfront capital investment in machinery and facilities. Lean manufacturing minimizes waste and enhances resource utilization by streamlining workflows and focusing on continuous improvement, resulting in lower operating costs and improved efficiency. While mass production emphasizes cost reduction via volume, lean manufacturing prioritizes cost savings through optimized labor, materials, and time allocation.

Quality Control and Waste Reduction

Mass production emphasizes high output with standardized quality control processes to maintain consistency, but often results in significant waste due to overproduction and inventory surplus. Lean manufacturing prioritizes continuous quality improvement and minimizes waste by implementing just-in-time production, rigorous defect prevention, and real-time feedback mechanisms. This approach reduces unnecessary costs and enhances product quality through streamlined workflows and employee involvement in identifying process inefficiencies.

Flexibility and Scalability in Operation

Mass production emphasizes high output with standardized processes, offering limited flexibility but excellent scalability for large volumes. Lean manufacturing prioritizes minimizing waste and optimizing workflow, enhancing operational flexibility to adapt quickly to changes in demand. Scalability in lean systems focuses on incremental improvements and resource efficiency, enabling smoother adjustments during production scale changes.

Impact on Workforce and Company Culture

Mass production emphasizes standardized tasks and repetitive work, often leading to a segmented workforce with limited skill development and reduced employee autonomy. Lean manufacturing fosters continuous improvement and employee involvement, promoting a collaborative culture where workers contribute to process innovation and take ownership of quality. This shift enhances job satisfaction, accountability, and a proactive mindset throughout the organization, driving greater operational agility.

Choosing the Right Approach for Your Business

Choosing the right manufacturing approach depends on business goals, product complexity, and market demand; mass production excels in high-volume, standardized goods with low unit costs, while lean manufacturing prioritizes waste reduction and flexibility for customized or variable products. Companies with stable demand and simplified product lines benefit from mass production's economies of scale, whereas those facing fluctuating orders or requiring fast turnaround gain from lean methods including continuous improvement (Kaizen) and just-in-time inventory. Analyzing factors such as production scale, cost constraints, and customer requirements helps determine whether mass production or lean manufacturing aligns better with operational efficiency and competitive advantage.

Mass Production Infographic

libterm.com

libterm.com