Regenerators improve energy efficiency by capturing and reusing heat from exhaust gases in industrial processes, reducing fuel consumption and emissions. These devices are essential in high-temperature operations such as steel production and glass manufacturing, ensuring optimal thermal recovery. Discover how regenerators can enhance your system's performance and sustainability by reading the full article.

Table of Comparison

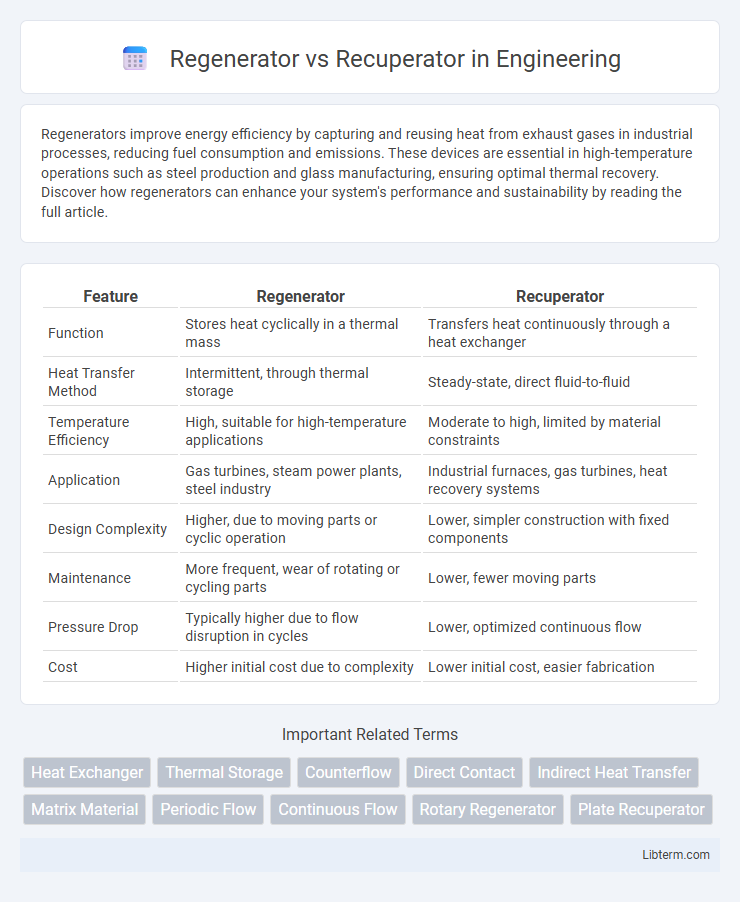

| Feature | Regenerator | Recuperator |

|---|---|---|

| Function | Stores heat cyclically in a thermal mass | Transfers heat continuously through a heat exchanger |

| Heat Transfer Method | Intermittent, through thermal storage | Steady-state, direct fluid-to-fluid |

| Temperature Efficiency | High, suitable for high-temperature applications | Moderate to high, limited by material constraints |

| Application | Gas turbines, steam power plants, steel industry | Industrial furnaces, gas turbines, heat recovery systems |

| Design Complexity | Higher, due to moving parts or cyclic operation | Lower, simpler construction with fixed components |

| Maintenance | More frequent, wear of rotating or cycling parts | Lower, fewer moving parts |

| Pressure Drop | Typically higher due to flow disruption in cycles | Lower, optimized continuous flow |

| Cost | Higher initial cost due to complexity | Lower initial cost, easier fabrication |

Introduction to Heat Exchangers

Regenerators and recuperators are two primary types of heat exchangers used to recover heat from exhaust gases in industrial processes and power plants. A regenerator temporarily stores heat in a thermal storage medium and transfers it cyclically between hot and cold fluids, making it suitable for applications with periodic flow. Recuperators use a continuous flow arrangement with a stationary heat transfer surface, enabling direct heat exchange between hot and cold streams for steady-state operations.

Overview of Regenerators

Regenerators are heat recovery devices that temporarily store heat from hot exhaust gases and transfer it to incoming cold air in a cyclic process, enhancing thermal efficiency in power plants and industrial furnaces. They consist of a rotating or fixed matrix, such as ceramic or metallic material, designed to absorb and release heat efficiently during alternate flows of hot and cold gases. Compared to recuperators, regenerators offer higher effectiveness in applications with fluctuating temperatures and intermittent operation due to their ability to store heat rather than continuously transfer it.

Overview of Recuperators

Recuperators are heat exchangers designed to recover waste heat from exhaust gases and transfer it to incoming air or fluid, improving overall energy efficiency in industrial processes and HVAC systems. They utilize a continuous flow of heat exchange, where hot exhaust gases pass through a heat transfer surface before being expelled, enabling the preheating of the incoming fluid. Compared to regenerators, recuperators offer simpler construction, continuous operation, and lower maintenance requirements, making them ideal for applications requiring steady-state heat recovery.

Key Differences: Regenerator vs Recuperator

Regenerators store heat temporarily in a thermal storage medium, such as a rotating wheel or fixed matrix, transferring it cyclically between hot and cold fluids, while recuperators provide continuous heat exchange through separate channels without direct contact or thermal storage. Regenerators excel in applications with cyclic or intermittent flow due to their ability to handle high temperatures and improve efficiency, whereas recuperators are suited for steady-state processes with lower temperature differences and lower pressure drops. Material selection for regenerators often emphasizes thermal capacity and durability against thermal stress, whereas recuperators prioritize corrosion resistance and compactness for effective heat transfer.

Working Principles Compared

A regenerator stores heat from hot exhaust gases in a thermal storage medium and transfers it to the incoming cold air in a cyclic process, maximizing energy recovery through intermittent heat exchange. A recuperator utilizes a continuous heat exchanger with separate flow channels, allowing hot exhaust gases to transfer heat directly to the incoming air without mixing fluids. The key difference lies in the regenerator's cyclic heat storage mechanism versus the recuperator's steady-state, direct heat transfer approach.

Applications and Industry Uses

Regenerators find extensive use in industries like steel manufacturing and glass production, where high-temperature heat recovery enhances energy efficiency by cyclically storing and releasing heat. Recuperators are commonly applied in gas turbines, furnaces, and waste heat recovery systems in power plants, optimizing continuous heat exchange between exhaust gases and incoming air. Both heat exchangers are vital in chemical processing and HVAC systems, with regenerators typically favored for batch processes and recuperators for continuous flow applications.

Advantages of Regenerators

Regenerators offer higher thermal efficiency by storing heat in a thermal storage medium and transferring it back to the process fluid, significantly reducing energy losses. They are particularly effective in applications with fluctuating temperatures and cyclical operations, where the intermittent heat transfer boosts overall system performance. Their compact design and ability to handle high-temperature gases make regenerators advantageous over recuperators in heavy-duty industrial processes.

Advantages of Recuperators

Recuperators offer significant energy efficiency by continuously transferring heat between exhaust gases and incoming air, reducing fuel consumption and lowering operational costs. Their compact design and low maintenance requirements make them ideal for industrial applications with space constraints and long-term performance needs. Enhanced heat recovery in recuperators also contributes to reduced emissions, supporting sustainability goals across manufacturing sectors.

Efficiency and Performance Analysis

Regenerators typically achieve higher thermal efficiency by temporarily storing heat in a thermal mass and then transferring it to the incoming cold fluid, making them ideal for applications with cyclic processes and fluctuating heat loads. Recuperators, using a continuous flow heat exchanger design, offer consistent performance with lower pressure drops and are preferred in steady-state operations where compactness and durability are crucial. Performance analysis reveals regenerators excel in maximizing energy recovery in batch systems, while recuperators provide superior efficiency in continuous flow scenarios due to their lower maintenance and operational stability.

Choosing Between a Regenerator and Recuperator

Choosing between a regenerator and recuperator depends on factors such as temperature ranges, application type, and efficiency requirements. Regenerators excel in high-temperature applications by cyclically storing and releasing heat through a thermal mass, making them ideal for steel mills and glass furnaces. Recuperators offer continuous heat exchange with less maintenance, suitable for moderate temperatures and applications like gas turbines and heat recovery boilers.

Regenerator Infographic

libterm.com

libterm.com