Salient poles are key components in synchronous machines, characterized by their projecting poles that create a non-uniform air gap, enhancing magnetic flux distribution. These poles improve machine performance by increasing the machine's torque and stability under varying load conditions. Discover how salient poles influence your electrical systems by exploring the detailed insights in the rest of this article.

Table of Comparison

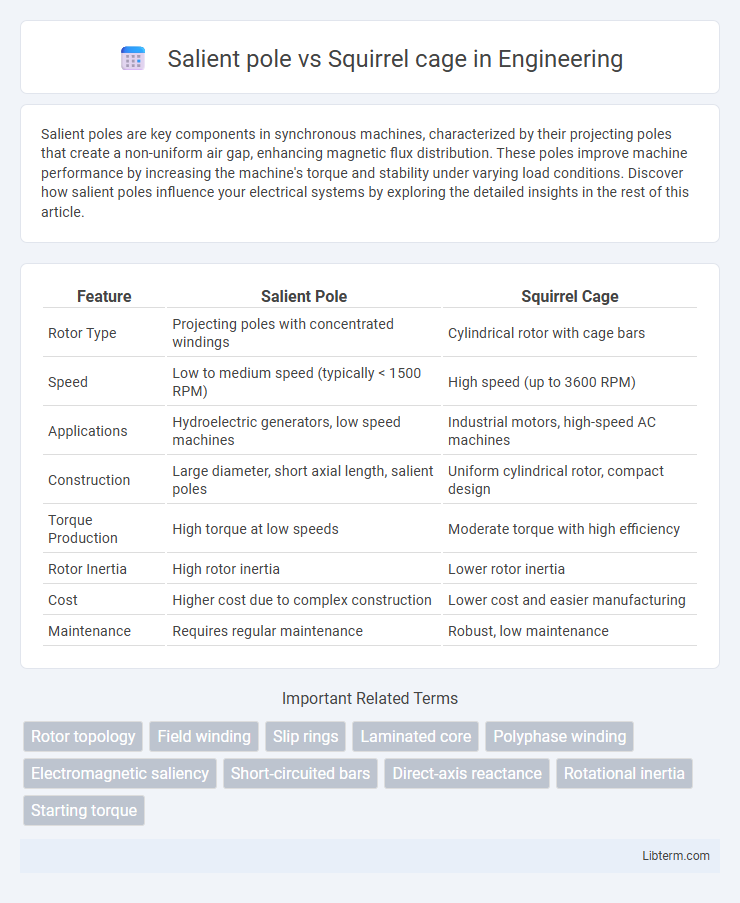

| Feature | Salient Pole | Squirrel Cage |

|---|---|---|

| Rotor Type | Projecting poles with concentrated windings | Cylindrical rotor with cage bars |

| Speed | Low to medium speed (typically < 1500 RPM) | High speed (up to 3600 RPM) |

| Applications | Hydroelectric generators, low speed machines | Industrial motors, high-speed AC machines |

| Construction | Large diameter, short axial length, salient poles | Uniform cylindrical rotor, compact design |

| Torque Production | High torque at low speeds | Moderate torque with high efficiency |

| Rotor Inertia | High rotor inertia | Lower rotor inertia |

| Cost | Higher cost due to complex construction | Lower cost and easier manufacturing |

| Maintenance | Requires regular maintenance | Robust, low maintenance |

Introduction to Salient Pole and Squirrel Cage Machines

Salient pole machines feature large, projecting poles mounted on the rotor, designed to provide high torque at low speeds, making them ideal for hydroelectric generators and applications requiring variable speed. Squirrel cage machines have a rotor composed of conductive bars short-circuited by end rings, producing a robust and maintenance-free design preferred for industrial motors operating at constant speed. Both types serve distinct roles in electrical engineering, with salient pole machines excelling in low-speed high-torque contexts and squirrel cage machines dominating in reliable, high-speed applications.

Design and Construction Differences

Salient pole rotors feature projecting poles with concentrated windings, typically used in low-speed synchronous machines, allowing efficient magnetic flux paths with laminated cores to reduce eddy current losses. Squirrel cage rotors consist of a cylindrical core with embedded conductors forming a cage-like structure, designed for high-speed induction motors, providing ruggedness and simplicity in construction without winding connections. The salient pole design emphasizes magnetic pole shapes and separate field coils, whereas the squirrel cage design integrates rotor bars short-circuited by end rings for induced current generation.

Working Principle and Operation

Salient pole machines operate on the principle of electromagnetic induction with distinct field poles projecting out from the rotor, creating a non-uniform air gap that enhances magnetic flux concentration and torque production at low speeds. Squirrel cage rotors use a cage-like structure made of conductive bars short-circuited by end rings, producing current and magnetic fields that induce rotor torque through relative motion between stator magnetic fields and rotor conductors. The salient pole's slow speed, high-pole design suits synchronous machines, while squirrel cage rotors enable efficient induction motor operation at higher speeds with simple, rugged construction.

Efficiency and Performance Comparison

Salient pole rotors exhibit lower efficiency due to higher windage and friction losses, making them suitable for low-speed applications but less optimal for high-performance requirements. Squirrel cage rotors offer superior efficiency with reduced maintenance and better performance at high speeds, thanks to their robust construction and uniform air gap. In industrial settings, squirrel cage motors deliver enhanced power factor and torque characteristics, resulting in improved overall operational efficiency compared to salient pole motors.

Applications in Industry

Salient pole rotors are extensively used in hydroelectric generators and low-speed applications due to their robust construction and excellent torque characteristics. Squirrel cage rotors dominate in industrial induction motors, favored for their simple design, durability, and efficient operation in high-speed machinery such as pumps, compressors, and conveyors. The choice depends on operating speed, load conditions, and maintenance requirements within sectors like manufacturing, power generation, and automotive industries.

Advantages of Salient Pole Machines

Salient pole machines offer superior low-speed torque and enhanced magnetic flux control due to their large, projecting poles, making them ideal for hydroelectric and slow-speed applications. Their robust construction ensures efficient operation with minimal noise and vibration, increasing reliability and reducing maintenance costs in industrial settings. These machines also provide higher excitation flexibility, enabling better performance customization compared to squirrel cage induction motors.

Advantages of Squirrel Cage Machines

Squirrel cage machines offer higher mechanical robustness and simpler construction compared to salient pole machines, resulting in lower maintenance requirements and increased reliability in industrial applications. Their design enables efficient operation at high speeds and better thermal performance, enhancing overall efficiency and longevity. The squirrel cage rotor's inherent short-circuiting capability provides improved starting torque and smooth operation under varying load conditions.

Maintenance and Reliability

Salient pole rotors require regular inspection and maintenance to ensure rotor winding integrity and pole shoe condition, as their construction is more prone to mechanical wear and insulation degradation. Squirrel cage rotors are known for higher reliability and lower maintenance needs due to their rugged design and absence of slip rings or brushes, reducing the risk of electrical faults. In terms of long-term operation, squirrel cage motors are preferred in applications demanding minimal downtime and consistent performance.

Cost and Economic Considerations

Salient pole rotors generally cost less to manufacture due to their simpler construction and use of laminated steel poles, making them economically advantageous for low-speed, high-torque applications such as hydroelectric generators. Squirrel cage rotors involve higher initial costs because of their solid aluminum or copper bars and end rings but offer superior durability and reduced maintenance expenses, leading to lower long-term operational costs in industrial settings. When evaluating total cost of ownership, salient pole rotors favor upfront affordability, whereas squirrel cage rotors deliver better economic efficiency over extended service life.

Choosing Between Salient Pole and Squirrel Cage Machines

Choosing between salient pole and squirrel cage machines depends on application requirements like speed, power, and efficiency. Salient pole machines excel in low-speed, high-torque scenarios such as hydroelectric generators due to their large pole construction and excellent magnetic flux characteristics. Squirrel cage machines suit high-speed industrial applications, offering robustness, minimal maintenance, and efficient performance in induction motors.

Salient pole Infographic

libterm.com

libterm.com