An outside circle is a circle that passes through all vertices of a polygon, encompassing it perfectly. Understanding its properties helps in solving geometric problems related to angles and distances. Explore the rest of the article to learn how the outside circle applies to various shapes and enhances your geometry skills.

Table of Comparison

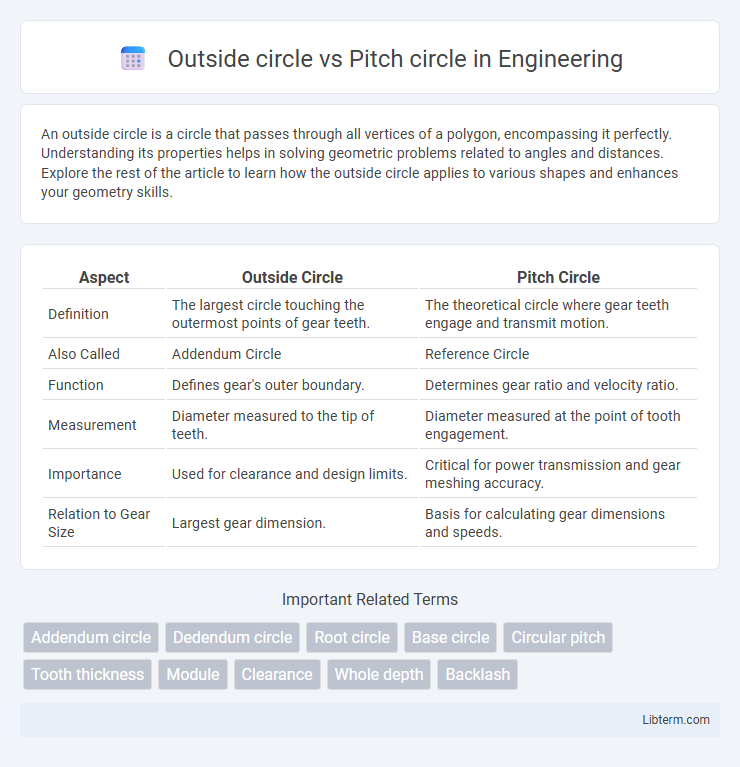

| Aspect | Outside Circle | Pitch Circle |

|---|---|---|

| Definition | The largest circle touching the outermost points of gear teeth. | The theoretical circle where gear teeth engage and transmit motion. |

| Also Called | Addendum Circle | Reference Circle |

| Function | Defines gear's outer boundary. | Determines gear ratio and velocity ratio. |

| Measurement | Diameter measured to the tip of teeth. | Diameter measured at the point of tooth engagement. |

| Importance | Used for clearance and design limits. | Critical for power transmission and gear meshing accuracy. |

| Relation to Gear Size | Largest gear dimension. | Basis for calculating gear dimensions and speeds. |

Understanding the Basics: Outside Circle vs Pitch Circle

The outside circle, or outer diameter, represents the total outer boundary of a gear or wheel, defining its maximum physical size. The pitch circle is an imaginary circle where gear teeth engage and transmit motion, crucial for calculating gear ratios and ensuring proper meshing. Understanding the distinction between the outside circle and pitch circle is essential for accurate gear design and mechanical compatibility.

Defining Outside Circle in Mechanical Design

The outside circle in mechanical design refers to the largest diameter that can encompass a gear or a circular object, defining its maximum external boundary. It is crucial for determining the overall size and clearance requirements of components in assemblies. Unlike the pitch circle, which represents the theoretical contact point for meshing gears, the outside circle defines the physical outer edge and impacts spatial constraints in mechanical systems.

What is a Pitch Circle?

A pitch circle refers to an imaginary circle that passes through the centers of the gear teeth where meshing occurs, crucial for defining gear geometry and ensuring proper engagement. Unlike the outside circle, which represents the outermost boundary of a gear, the pitch circle determines the effective diameter used for calculating gear ratios and velocities. Accurate measurement of the pitch circle diameter is essential for designing compatible gears and maintaining transmission efficiency in mechanical systems.

Key Differences Between Outside Circle and Pitch Circle

The outside circle refers to the outermost boundary of a gear or circular object, defining its maximum diameter, while the pitch circle is an imaginary circle that represents the effective contact point between mating gears for transmitting motion. The pitch circle diameter is crucial for gear calculations, tooth spacing, and synchronization, whereas the outside circle diameter determines the physical size and clearance requirements of the gear. Understanding the distinction is essential for accurate gear design, ensuring proper meshing and efficient power transmission.

Importance of Pitch Circle in Gear Systems

The pitch circle is a fundamental concept in gear systems, representing the imaginary circle where two gears effectively engage, ensuring accurate transmission of motion and torque. Unlike the outside circle, which marks the physical boundary of a gear, the pitch circle determines gear ratio, center distance, and smooth operation. Precise calculation of the pitch circle diameter is crucial for maintaining gear mesh efficiency and minimizing wear in mechanical transmissions.

Applications of Outside Circle in Engineering

The outside circle, defined as the circle passing through the outermost points of a gear's teeth, is crucial in engineering applications where precise gear meshing and clearance are required, such as in high-speed machinery and automotive transmissions. Its measurement ensures that gears maintain proper interference levels and avoid contact beyond the pitch circle, reducing wear and enhancing durability. Engineers rely on the outside circle dimension to design gear housings and verify tolerances in manufacturing processes for optimal mechanical performance.

Measurement Techniques for Both Circles

Outside circle measurement involves determining the maximum diameter of a gear or wheel by using tools like calipers or micrometers to capture the outermost points. Pitch circle measurement requires specialized instruments such as gear tooth calipers or coordinate measuring machines (CMM) to accurately assess the imaginary circle passing through the gear teeth's pitch points. Accurate measurement of both circles is essential for gear design, ensuring proper meshing and performance in mechanical systems.

Impacts on Performance: Outside Circle vs Pitch Circle

The outside circle diameter influences the overall size and fits of gears, impacting the gear mesh engagement and clearance more significantly than the pitch circle, which primarily determines the theoretical point of contact and velocity ratio between gears. Variations in outside circle can lead to increased radial forces and potential vibration, affecting smoothness and noise levels during operation. In contrast, pitch circle accuracy ensures proper power transmission and load distribution, directly affecting gear efficiency and lifespan.

Common Mistakes in Identifying Circles

Confusing the outside circle with the pitch circle often leads to measurement errors in gear and bolt analysis, as the outside circle refers to the outermost edge while the pitch circle lies centrally between the gear's teeth. Misidentifying these circles can cause incorrect calculations in gear ratios, torque transmission, and bolt hole positions. Precise identification requires understanding that the pitch circle diameter (PCD) is the standard reference for mechanical fitting, whereas the outside circle diameter (OCD) is used for overall size assessment.

Choosing the Right Circle for Your Application

Choosing the right circle--outside circle or pitch circle--depends on the specific engineering requirements of your application, such as load distribution and rotational accuracy. The pitch circle represents the effective diameter where gear teeth engage, essential for proper meshing and efficiency, while the outside circle defines the maximum diameter, impacting clearance and housing design. Prioritizing pitch circle diameter ensures optimal gear performance, whereas the outside circle is critical for spatial fit within assemblies.

Outside circle Infographic

libterm.com

libterm.com