Piezoelectric materials generate electric charge in response to mechanical stress, making them essential in sensors, actuators, and energy harvesting devices. Their unique properties enable precise control and efficient energy conversion in various applications. Discover how these materials can enhance your next project by exploring the full article.

Table of Comparison

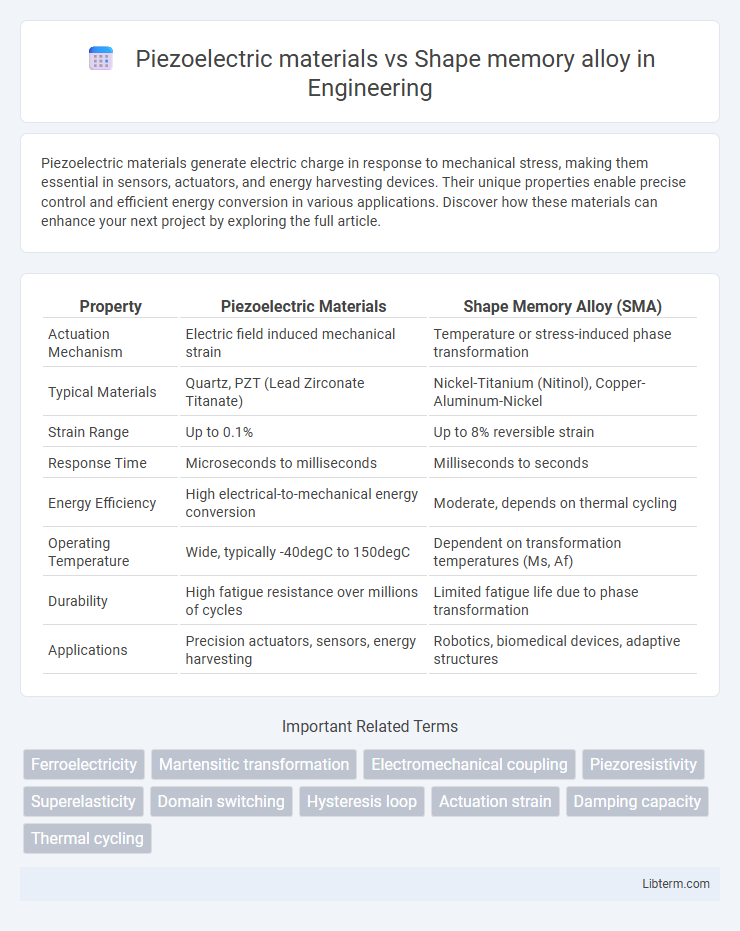

| Property | Piezoelectric Materials | Shape Memory Alloy (SMA) |

|---|---|---|

| Actuation Mechanism | Electric field induced mechanical strain | Temperature or stress-induced phase transformation |

| Typical Materials | Quartz, PZT (Lead Zirconate Titanate) | Nickel-Titanium (Nitinol), Copper-Aluminum-Nickel |

| Strain Range | Up to 0.1% | Up to 8% reversible strain |

| Response Time | Microseconds to milliseconds | Milliseconds to seconds |

| Energy Efficiency | High electrical-to-mechanical energy conversion | Moderate, depends on thermal cycling |

| Operating Temperature | Wide, typically -40degC to 150degC | Dependent on transformation temperatures (Ms, Af) |

| Durability | High fatigue resistance over millions of cycles | Limited fatigue life due to phase transformation |

| Applications | Precision actuators, sensors, energy harvesting | Robotics, biomedical devices, adaptive structures |

Introduction to Smart Materials

Smart materials, such as piezoelectric materials and shape memory alloys, exhibit unique properties that enable adaptive responses to external stimuli. Piezoelectric materials generate electric charge under mechanical stress, making them ideal for sensors and actuators, while shape memory alloys undergo reversible phase transformations to return to predetermined shapes, providing applications in actuators and biomedical devices. These distinct mechanisms highlight the versatility of smart materials in advanced engineering and responsive system design.

Overview of Piezoelectric Materials

Piezoelectric materials generate electric charge in response to mechanical stress, making them essential in sensors, actuators, and energy harvesting devices. Common piezoelectric materials include quartz, lead zirconate titanate (PZT), and barium titanate, known for high sensitivity and fast response times. These materials contrast with shape memory alloys, which rely on phase transformations to recover original shapes upon heating rather than converting mechanical energy directly to electrical signals.

Fundamentals of Shape Memory Alloys

Shape memory alloys (SMAs) are metallic materials that can recover their original shape after deformation through a reversible phase transformation between martensite and austenite structures. Unlike piezoelectric materials, which generate electric charge under mechanical stress, SMAs rely on thermomechanical effects to exhibit shape memory and superelasticity properties. The fundamental mechanism of SMAs involves temperature-dependent phase changes that enable actuation without the need for electrical input, making them ideal for applications requiring large, recoverable strains.

Comparison of Working Mechanisms

Piezoelectric materials generate electric charge in response to mechanical stress through the direct piezoelectric effect, relying on crystalline lattice deformation to convert mechanical energy into electrical energy. Shape memory alloys function via a reversible phase transformation between austenite and martensite structures, allowing them to recover predefined shapes after deformation upon heating or mechanical unloading. While piezoelectric materials operate based on electro-mechanical coupling at the atomic lattice level, shape memory alloys depend on thermo-mechanical phase transformation for their actuation mechanism.

Key Material Properties

Piezoelectric materials exhibit the ability to generate an electric charge in response to mechanical stress, characterized by high sensitivity and fast response times, making them ideal for sensors and actuators. Shape memory alloys (SMAs) possess unique superelasticity and shape recovery properties due to phase transformations between martensite and austenite, enabling large deformation and actuation capabilities. While piezoelectric materials typically have high piezoelectric coefficients (d33 values up to 1000 pC/N), SMAs offer recovery strains up to 8-10% and operate effectively under different mechanical and thermal stimuli.

Applications in Engineering and Technology

Piezoelectric materials are widely used in precision sensors, actuators, and energy harvesting devices due to their ability to convert mechanical stress into electrical signals. Shape memory alloys (SMAs) find applications in aerospace, robotics, and biomedical devices, leveraging their unique ability to undergo reversible deformation and return to their original shape upon heating. Engineering applications often combine both materials to optimize performance in adaptive structures and smart systems.

Response Speed and Efficiency

Piezoelectric materials exhibit ultra-fast response speeds in the microsecond to millisecond range, making them ideal for high-frequency applications and precise actuation with high energy conversion efficiency over short cycles. Shape memory alloys (SMAs) respond more slowly, typically in the range of milliseconds to seconds, due to thermal phase transformation processes that incur higher hysteresis and energy loss, resulting in lower efficiency for rapid actuation. The high response speed and efficient energy conversion of piezoelectric materials surpass the relatively slower and less energy-efficient actuation of shape memory alloys in dynamic performance-critical applications.

Durability and Lifespan

Piezoelectric materials exhibit high durability with lifespans often exceeding 100 million cycles due to their robust crystalline structure, making them ideal for long-term sensing applications. Shape memory alloys (SMAs) generally have shorter lifespans, typically ranging from 10,000 to 1,000,000 cycles, as repeated phase transformations induce material fatigue. The inherent brittleness of piezoelectric ceramics contrasts with the fatigue-prone nature of SMAs, dictating application-specific durability considerations.

Cost and Availability

Piezoelectric materials generally offer lower upfront costs and are widely available in commercial markets due to their extensive use in sensors and actuators. Shape memory alloys tend to be more expensive because of complex manufacturing processes and limited raw material sources, such as nickel-titanium (Nitinol). The availability of shape memory alloys is more restricted, often requiring specialized suppliers, while piezoelectric ceramics like PZT are mass-produced and readily accessible.

Future Trends and Research Directions

Piezoelectric materials are evolving with advancements in flexible electronics and energy harvesting, emphasizing nanostructured composites and enhanced sensitivity for wearable and biomedical applications. Shape memory alloys (SMAs) focus on improving fatigue life, response speed, and biocompatibility, while exploring novel alloy compositions like high-entropy and titanium-based SMAs for aerospace and robotic actuators. Future research highlights integrating piezoelectric materials with SMAs for multifunctional smart systems, leveraging AI-driven design and additive manufacturing for customized, efficient, and durable actuators and sensors.

Piezoelectric materials Infographic

libterm.com

libterm.com