Internal combustion engines convert the energy from fuel into mechanical power through controlled explosions within the engine's cylinders. This process is fundamental to the operation of most vehicles, powering everything from cars to motorcycles with efficiency and reliability. Explore the article to understand how internal combustion engines work and their impact on transportation technology.

Table of Comparison

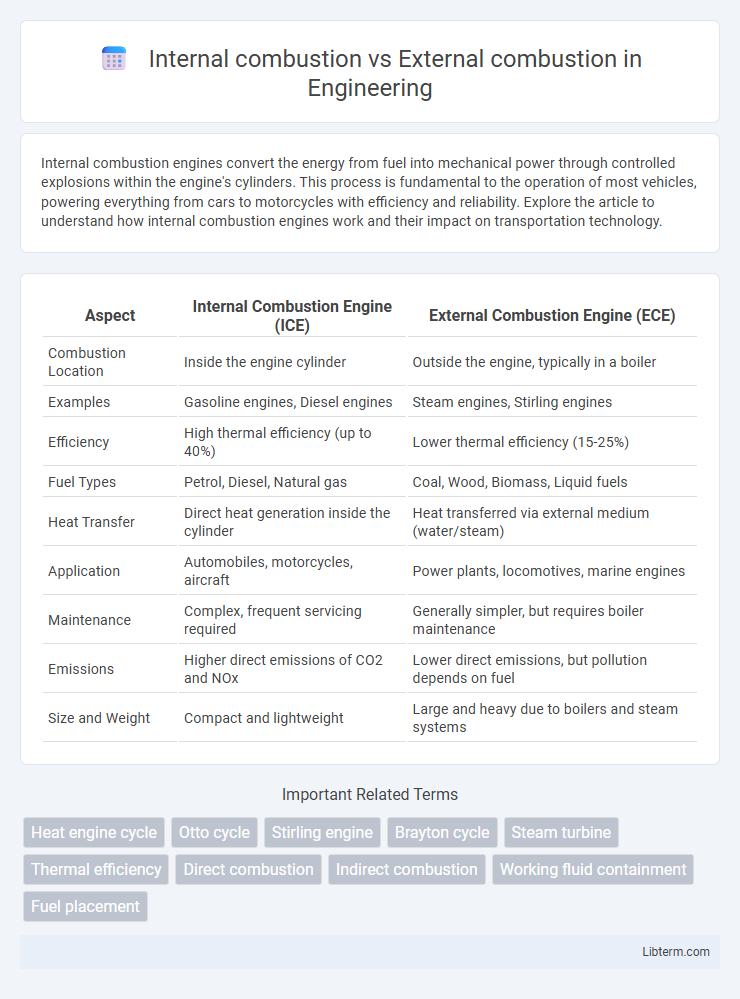

| Aspect | Internal Combustion Engine (ICE) | External Combustion Engine (ECE) |

|---|---|---|

| Combustion Location | Inside the engine cylinder | Outside the engine, typically in a boiler |

| Examples | Gasoline engines, Diesel engines | Steam engines, Stirling engines |

| Efficiency | High thermal efficiency (up to 40%) | Lower thermal efficiency (15-25%) |

| Fuel Types | Petrol, Diesel, Natural gas | Coal, Wood, Biomass, Liquid fuels |

| Heat Transfer | Direct heat generation inside the cylinder | Heat transferred via external medium (water/steam) |

| Application | Automobiles, motorcycles, aircraft | Power plants, locomotives, marine engines |

| Maintenance | Complex, frequent servicing required | Generally simpler, but requires boiler maintenance |

| Emissions | Higher direct emissions of CO2 and NOx | Lower direct emissions, but pollution depends on fuel |

| Size and Weight | Compact and lightweight | Large and heavy due to boilers and steam systems |

Introduction to Combustion Engines

Internal combustion engines generate power by igniting fuel-air mixtures directly within the engine cylinder, resulting in rapid expansion of gases that drive pistons. External combustion engines, such as steam engines, burn fuel outside the engine to produce steam, which then transfers energy to mechanical components. The efficiency and compact design of internal combustion engines have made them predominant in automotive applications, while external combustion engines are often used in industrial settings and power plants.

Defining Internal Combustion Engines

Internal combustion engines (ICE) generate power through the combustion of fuel directly inside the engine's cylinders, producing high-pressure gases that move pistons. These engines are characterized by rapid energy conversion and compact design, commonly used in automobiles, motorcycles, and small aircraft. In contrast, external combustion engines burn fuel outside the engine, transferring heat to a working fluid, as seen in steam engines and power plants.

Overview of External Combustion Engines

External combustion engines operate by burning fuel outside the engine cylinder, converting heat into mechanical energy through a working fluid like steam. These engines typically exhibit higher fuel flexibility and lower emissions compared to internal combustion engines, making them suitable for applications such as power plants and marine propulsion. Steam turbines and Stirling engines exemplify efficient external combustion technologies, utilizing external heat sources to generate continuous and reliable power output.

Key Differences Between Internal and External Combustion

Internal combustion engines burn fuel directly inside the engine cylinders, resulting in high thermal efficiency and rapid power generation, whereas external combustion engines combust fuel outside the engine, typically in a boiler, transferring heat to a working fluid like steam. Internal combustion engines are generally more compact and suitable for automobiles, while external combustion engines, such as steam engines, are larger and primarily used in power plants. The key differences lie in combustion location, heat transfer method, engine size, and typical applications.

Historical Development of Combustion Technologies

Internal combustion engines emerged prominently in the 19th century with Nikolaus Otto's four-stroke engine in 1876, revolutionizing transportation by converting fuel combustion directly into mechanical energy within the engine cylinder. External combustion engines, originating in the late 17th century with Thomas Newcomen's steam engine, utilized external heat sources to generate steam that powered mechanical work, dominating industrial applications through the 18th and early 19th centuries. The transition from steam-powered external combustion to more efficient, compact internal combustion engines marked a pivotal shift in engine technology driven by advancements in fuel technology and thermodynamics.

Efficiency Comparison: Internal vs External

Internal combustion engines typically achieve higher thermal efficiency, often ranging between 25% to 30%, due to direct fuel combustion within the engine's cylinders, which minimizes energy loss. External combustion engines, such as steam engines, generally exhibit lower efficiency levels around 10% to 20%, as heat transfer through a boiler and heat exchanger introduces additional energy dissipation. Advances in internal combustion technology, including turbocharging and fuel injection, further enhance efficiency, outpacing the largely limited improvements in external combustion systems.

Applications and Real-World Uses

Internal combustion engines dominate automotive and aviation industries due to their high power-to-weight ratio and rapid response, powering cars, motorcycles, airplanes, and marine vessels. External combustion engines, including steam turbines and steam engines, find extensive use in power generation plants, industrial machinery, and historical railway locomotives, benefiting from fuel flexibility and sustained energy output. Both engine types contribute to transportation and energy sectors, with internal combustion preferred for mobility and external combustion favored for steady, large-scale power production.

Environmental Impact Assessment

Internal combustion engines produce higher levels of greenhouse gases such as CO2 and NOx due to the direct burning of fossil fuels within the engine cylinders, contributing significantly to air pollution and climate change. External combustion engines, like steam turbines, burn fuel externally, allowing for more controlled combustion processes and potentially lower emissions when combined with efficient filtration systems. Environmental Impact Assessments (EIA) highlight that internal combustion engines generally have a larger carbon footprint and pollutant output, whereas external combustion systems may offer better opportunities for emission control and integration with renewable energy sources.

Future Trends in Combustion Engine Design

Future trends in combustion engine design emphasize hybrid systems integrating internal combustion engines (ICE) with electric power to reduce emissions and improve efficiency. Advances in internal combustion focus on direct fuel injection, variable valve timing, and alternative fuels like hydrogen to enhance performance and sustainability. External combustion engines may see renewed interest through developments in Stirling and Rankine cycles for micro combined heat and power (CHP) systems, supporting decarbonization goals in industrial applications.

Conclusion: Choosing the Right Engine Type

Internal combustion engines excel in efficiency and compact design, making them ideal for vehicles and portable machinery requiring quick power delivery. External combustion engines, such as steam turbines, provide greater fuel flexibility and lower emissions, suitable for stationary power plants and industrial applications. Selecting the right engine depends on factors like energy efficiency, application purpose, fuel availability, and environmental impact.

Internal combustion Infographic

libterm.com

libterm.com